Introduction

In the fast-paced arena of modern manufacturing, where every second counts, the efficiency of assembly lines can be the linchpin between success and stagnation. Downtime,that silent thief of productivity,looms as an ever-present challenge,costing industries not just in lost revenue but in potential growth and innovation.As technology continues to evolve, the integration of Supervisory Control and Data Acquisition (SCADA) dashboards is emerging as a beacon of hope for manufacturers seeking to streamline operations and enhance real-time decision-making. By harnessing the power of data visualization, these complex tools provide operators with critical insights, enabling them to identify bottlenecks, predict failures, and respond proactively to issues on the shop floor. In this article,we will explore how the strategic utilization of SCADA dashboards can transform assembly line operations,reduce downtime,and ultimately pave the way for a more resilient and responsive manufacturing environment. Join us as we delve into the synergies of technology and efficiency, uncovering best practices and innovative approaches that can redefine the very framework of industrial productivity.

Maximizing Efficiency Through Real-Time Data Visualization

Real-time data visualization through SCADA dashboards empowers assembly line operators and managers to make swift, informed decisions that radically reduce downtime. By presenting crucial metrics at a glance, these dashboards illuminate patterns and anomalies, enabling teams to react proactively rather than reactively. For example, operators can quickly identify bottlenecks in production, material shortages, or equipment failures, allowing them to implement corrective actions without delay. This immediacy not only fosters smoother operational flows but also enhances overall productivity.

Moreover, integrating real-time data visualization into existing systems can streamline interaction between different departments. consider the benefits of using real-time metrics to facilitate cross-departmental collaboration:

- Instant Alerts: Notifications of issues directly sent to relevant personnel.

- Trend Analysis: Visual portrayal of performance over time to spot recurring problems.

- Resource Allocation: Dynamic adjustments based on the current operational status.

| Metric | Before Implementation | After Implementation |

|---|---|---|

| Downtime (Hours/Week) | 20 | 5 |

| Production Rate (Units/Hour) | 50 | 80 |

| Operational Costs (USD/Week) | 5000 | 3000 |

Identifying Bottlenecks and proactive Problem Solving

In the realm of assembly line operations, recognizing bottlenecks is crucial for maintaining efficiency and minimizing downtime. SCADA dashboards serve as a powerful tool for operators, presenting real-time data that highlights inefficiencies and anomalies in the production process. By analyzing patterns in machinery performance, labor productivity, and material flow, teams can pinpoint exactly where delays are occurring. Key indicators to monitor include:

- Machine utilization rates – Understanding how often and effectively machines are being used can reveal potential overuse or underuse issues.

- Cycle times – Analyzing the time it takes to complete a specific task can help identify prolonged durations that suggest process improvements.

- Downtime events – Tracking the frequency and duration of downtime incidents allows for a focused approach to mitigating issues that disrupt workflow.

Proactive problem-solving techniques become highly effective when issues are surfaced early on through these dashboards. Implementing predictive maintenance strategies can avert machine failures before they occur, saving costly production hours. Additionally, fostering a culture of continuous improvement within the team encourages operators to communicate insights gathered from dashboard readings, leading to innovative solutions. In order to prioritize response actions, teams can employ a simple prioritization table:

| Issue | Impact Level | Action Required |

|---|---|---|

| Frequent Equipment Failures | High | Immediate Inspection |

| Slow Production Speed | Medium | Process Review |

| Minor Material Shortages | Low | Inventory Check |

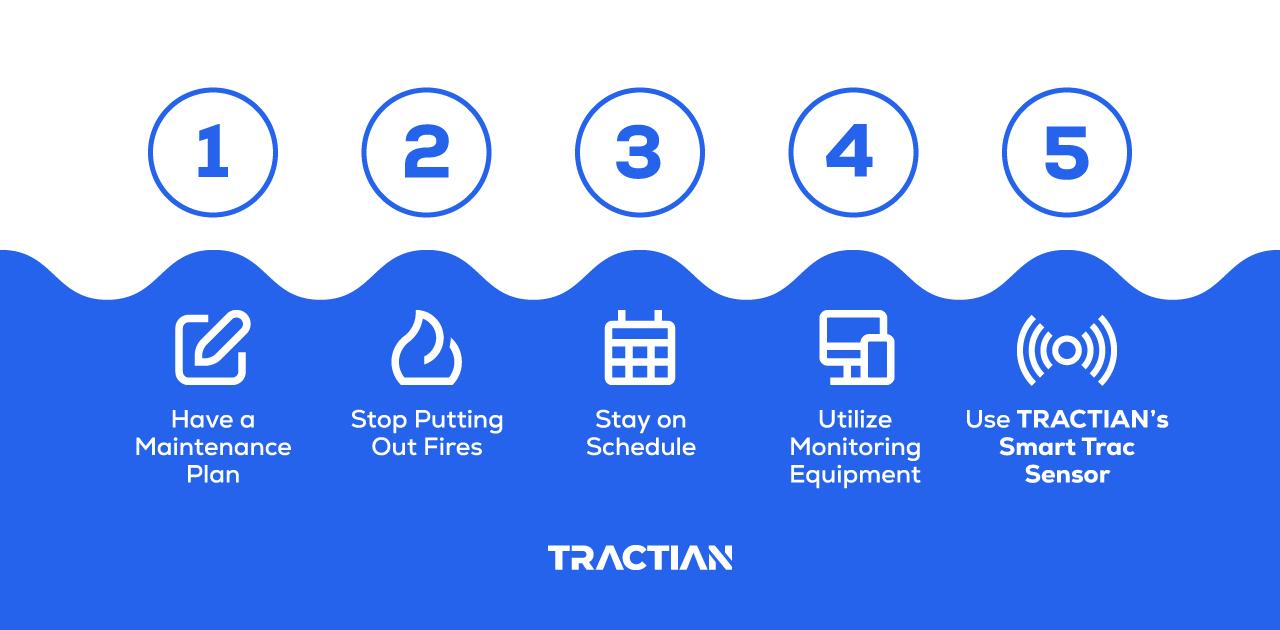

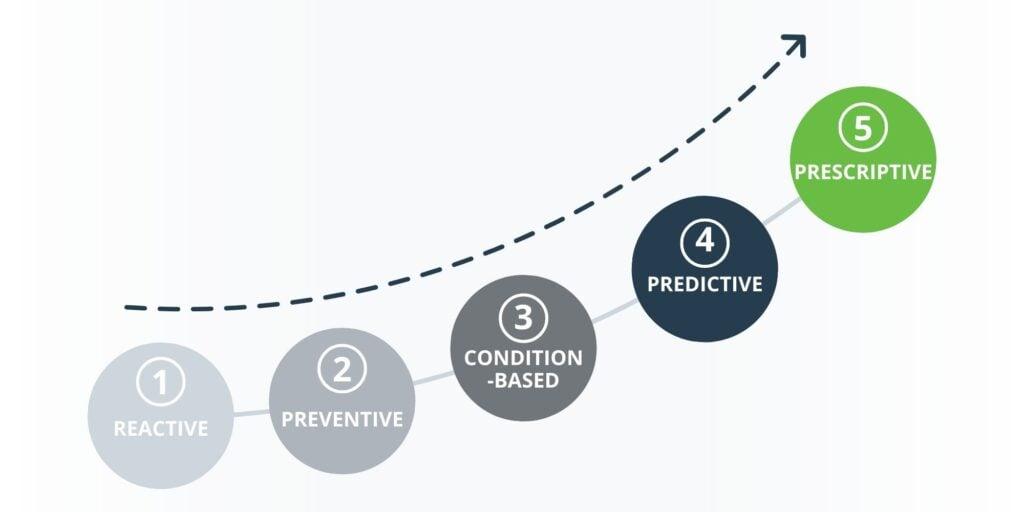

Implementing Predictive Maintenance Strategies for Longevity

Integrating predictive maintenance strategies within SCADA dashboards can profoundly enhance the lifespan of assembly line equipment.By leveraging real-time data analytics, operators can identify wear patterns and potential failures before they escalate into major breakdowns.This proactive approach not only minimizes costly downtimes but also ensures that the machinery operates at peak efficiency.Key benefits include:

- Early Detection: Monitor indicators like vibration and temperature to catch issues early.

- Data-Driven Decision Making: Use insights from ancient data to optimize maintenance schedules.

- Cost Efficiency: Reduce needless maintenance checks and associated costs.

Moreover, the integration of machine learning algorithms into SCADA systems can refine predictive models, allowing for more accurate forecasts of equipment performance. Consider setting up a feedback loop where the system learns from past maintenance records and adapts its predictions accordingly.A structured approach can include the following steps:

| Step | Description |

|---|---|

| Data Collection | Gather data from sensors and historical maintenance logs. |

| Analysis | Use analytics to identify patterns indicative of potential failures. |

| Action Plan | Develop and implement maintenance strategies based on predictive insights. |

Enhancing Collaboration and Communication Among Teams

Effective collaboration and seamless communication are the cornerstones of any successful manufacturing operation, especially when utilizing SCADA dashboards to monitor assembly lines. By integrating real-time data analytics, teams can access instant updates concerning equipment performance, production metrics, and potential bottlenecks. This shared access fosters a cohesive environment where all team members are aligned with the assembly line’s objectives, leading to informed decision-making that significantly reduces downtime. Teams can leverage this data to conduct regular huddles or status updates, ensuring that vital information is disseminated promptly.

Furthermore, incorporating digital communication tools enhances the overall workflow by bridging the gap between cross-functional teams. By establishing a unified communication platform, such as chat applications or dedicated project management tools, team members can easily share insights or escalate issues as they arise. The simplicity of access to data allows for more effective problem resolution, which is crucial in fast-paced assembly environments. Below is a comparative table showcasing conventional versus enhanced communication methods:

| Method | Traditional Communication | Enhanced Communication |

|---|---|---|

| Response Time | Delayed, reactive | Immediate, proactive |

| Information Sharing | Limited to meetings | Real-time updates |

| Problem Resolution | Reactive solutions | Collaborative approach |

In Conclusion

In the fast-paced world of manufacturing, every second counts.As we’ve explored in this article,the integration of SCADA dashboards serves as a pivotal strategy for minimizing downtime on assembly lines. By providing real-time insights, promoting proactive maintenance, and enabling swift decision-making, these dynamic tools empower organizations to maintain productivity and enhance operational efficiency.

As industries continue to evolve,the importance of harnessing technology to streamline processes becomes ever more pronounced.As we move forward, embracing innovative solutions like SCADA dashboards will not only keep assembly lines running smoothly but also pave the way for a more resilient manufacturing future. By investing in these digital enhancements,companies can unlock the potential for critically important cost savings and improved reliability,ensuring they stay competitive in an increasingly complex market landscape.

the journey toward reducing downtime is ongoing, and with the right tools at our disposal, we can navigate this path with greater confidence and clarity. Let us move forward, driven by data, and continue to transform our operations for a more efficient tomorrow.