Introduction: MES Integration in Multi-Line Food Production: Ignition as the Hub

In the dynamic landscape of food production, efficiency adn precision are paramount. Multi-line food production facilities, frequently enough dealing with intricate processes and diverse product portfolios, necessitate robust systems that can seamlessly manage and integrate these complexities.Manufacturing Execution Systems (MES) have emerged as pivotal tools, bridging the gap between enterprise-level planning and real-time production operations. At the heart of this change is Ignition by Inductive Automation—an innovative platform that serves as a central hub for MES integration, enhancing operational visibility and control.

Ignition stands out as a versatile solution,offering a myriad of features that cater specifically to the needs of multi-line food production facilities. It provides a holistic view of manufacturing processes, enabling seamless interaction and data flow across different production lines. In this technical article, we delve into the myriad ways Ignition can be leveraged to optimize MES integration, reduce manual errors, and elevate production standards.

Key discussion points include:

- Centralized Data Management: By acting as a central node,Ignition facilitates the collection,association,and analysis of data from multiple production lines,ensuring data consistency and accessibility.

- Real-Time Monitoring and control: Ignition’s powerful visualization tools enable real-time monitoring of production line performance, helping identify bottlenecks and inefficiencies.

- Scalability and Adaptability: Designed with flexibility in mind, Ignition supports the easy scaling of operations, adapting to expanding production needs without compromising on performance.

- Enhanced Traceability and Compliance: With thorough logging and reporting capabilities,Ignition ensures traceability and compliance with stringent food safety standards.

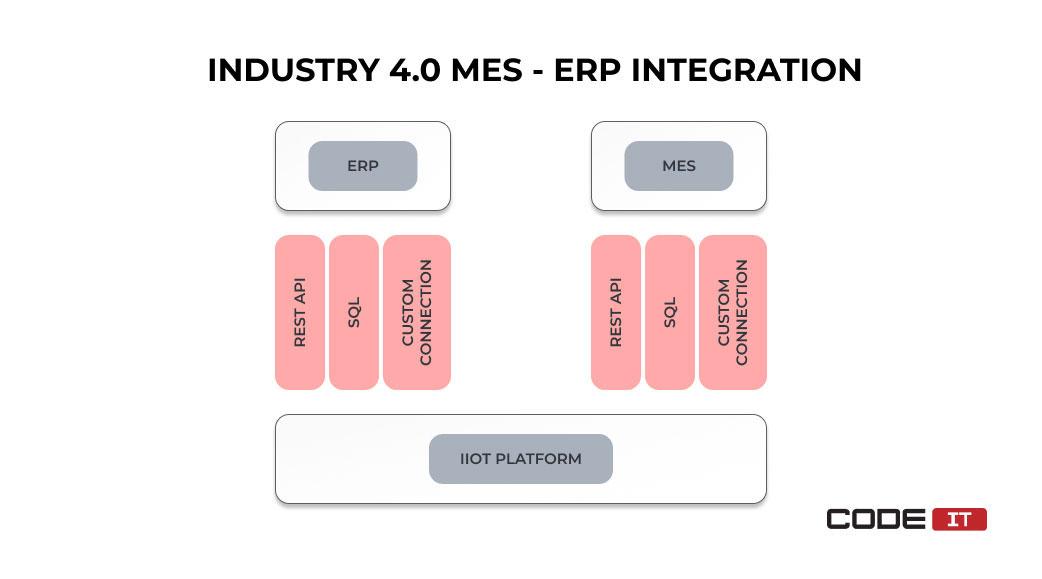

- Seamless Integration with Existing Systems: Ignition integrates effortlessly with existing ERP and SCADA systems, providing a unified platform for data exchange and operational control.

Through pertinent examples and technical insights, this article aims to equip facilities with the knowledge to harness the full potential of Ignition in their MES environments, driving innovation, safety, and sustainability in food production.

MES Integration Challenges and Opportunities in Multi-Line Food Production

Implementing a Manufacturing Execution System (MES) in a multi-line food production facility presents a unique set of challenges that require strategic overcoming to ensure smooth integration. one important challenge is achieving seamless data connectivity across diverse, often siloed, production lines. These lines may have varied machinery with different protocols, making standardization difficult. For instance, older packaging machines using legacy systems may not easily communicate with newer equipment employing modern IoT technology. Utilizing Ignition as a central hub allows for the integration of disparate systems through its wide selection of protocol support like OPC UA, modbus, and MQTT, ensuring that data flows cohesively throughout the facility.This interconnectivity minimizes manual data entry, thus reducing human error and improving traceability across all lines, thereby enhancing operational clarity.

Another notable opportunity in MES integration is the advancement of production scheduling and resource allocation. Multi-line operations can be complex, often leading to inefficiencies if not managed correctly. Ignition’s robust architecture supports real-time data analytics that aids in dynamic scheduling,optimizing resource use,and enhancing yield tracking. For example, an Ignition-driven yield tracking system can pinpoint yield loss occurrences such as overfills or waste, allowing production managers to make data-informed decisions swiftly. Enhanced visibility into production metrics not only improves the decision-making process but also facilitates faster responses to any compliance deviations. By providing a comprehensive view of the production landscape, businesses can cultivate a safer, more efficient operations habitat that is both resilient and agile.

Leveraging Ignition as a Centralized Hub for Seamless Communication and Data Flow

In the dynamic landscape of multi-line food production, Ignition stands out as a centralized hub, enabling seamless communication and data flow across different production lines. By acting as an operational nerve center,Ignition facilitates the integration of various equipment and systems,such as PLCs,HMIs,and databases,allowing them to communicate effortlessly. This streamlining is notably advantageous in environments where multiple product lines need synchronized updates and real-time adjustments. For example, if a batch recipe for a dairy product changes slightly due to seasonal ingredient availability, Ignition’s centralized control can dispatch these adjustments simultaneously to all production lines, ensuring consistency and compliance.Through real-time data collection and distribution, any potential issues such as equipment downtime or product line discrepancies can be promptly identified and addressed, significantly reducing the risk of costly production errors.

additionally, Ignition’s role as a central hub extends to comprehensive data integration and accessibility, transforming raw data into actionable insights. Imagine a scenario where a multi-line production facility aims to improve yield tracking and minimize wastage. Ignition collects data from each line, aggregates it, and presents it through intuitive dashboards and reports.This visibility allows operators and managers to monitor production KPIs in real-time, harness predictive analytics to preemptively identify equipment that may fail, and deploy resources more effectively.Furthermore, with automated recipe management, schedules can be dynamically adjusted based on current production demands and past data, accelerating decision-making processes. By grounding operations within a centralized, integrated system, Ignition not only reduces human error but also improves traceability and enhances both safety and quality control across the board.

Enhancing Production Efficiency and Minimized Downtimes through Ignition-Based Integration

Incorporating Ignition-based automation into multi-line food production plants transforms the way facilities handle production efficiency and minimize downtimes. By dynamically adjusting to production demands, Ignition allows seamless integration with legacy systems and modern machines, paving the way for a cohesive operational framework. As a notable example, consider a beverage production facility managing three separate production lines. Utilizing Ignition’s capabilities, line managers can gain real-time insights even during peak production hours without the necessity of physical intervention. This ensures that production runs smoothly by predicting equipment needs and scheduling maintenance automatically when the load on particular lines drops or when anomalies are detected, reducing instances of unscheduled downtimes.

Moreover, the integration with Manufacturing Execution systems (MES) via Ignition facilitates meticulous tracking of production processes. This is achieved by connecting diverse data points across the facility into a centralized dashboard that can be accessed anytime, anywhere. The impact is profound: operators can swiftly adapt to market changes by modifying production recipes without stopping the production lines, ensuring minimal disruption. Through features like automated alerts for equipment malfunction or operator input errors, Ignition prevents costly mistakes and maintains a high standard of product quality. Moreover, batch scheduling and shift management become fluid processes, optimizing resource use and aligning seamlessly with supply chain requirements for components like packaging materials and raw ingredients.

Best Practices and Technical Recommendations for Successful MES Implementation with Ignition

When implementing an MES in a multi-line food production environment using Ignition, it’s crucial to focus on standardization of data models and communication protocols across different lines. These standardization practices ensure that all data,regardless of its origin,is seamlessly integrated into ignition’s central hub,enabling consistent performance metrics and facilitating cross-line analysis. For example, consider a facility that processes both dairy and baked goods; standardizing alarms and PID loops can eliminate discrepancies and improve monitoring efficiency, ultimately reducing the risk of product contamination due to equipment malfunction. Adopting OPC UA as your primary communication standard in the MES environment simplifies system integration, allowing diverse equipment like mixers, ovens, and pasteurizers to communicate effectively within one unified platform.

Another technical recommendation for MES implementation involves leveraging Ignition’s modular architecture. By utilizing Ignition’s various modules like the Reporting, Vision, and Perspective modules, food and beverage facilities can create a highly customizable and scalable MES platform. This modular approach not only facilitates a phased implementation, minimizing operational disruption, but also allows facilities to tailor solutions to their specific production needs. As an example, a beverage manufacturer can start by integrating batch management and then sequentially enhance their system with real-time yield tracking using the Ignition Edge EAM module. Additionally, leveraging ignition’s robust scripting environment provides the flexibility to automate task scheduling and enhance traceability, reducing labor-intensive processes and promoting real-time decision-making capabilities.

Future Outlook

the integration of a Manufacturing Execution System (MES) within a multi-line food production environment, with Ignition serving as the central hub, presents numerous advantages that streamline operations and elevate productivity. Key takeaways from this exploration include:

- Enhanced Traceability and Compliance: Ignition enables meticulous tracking of products throughout the production line, ensuring adherence to regulatory standards and simplifying audits.

- Improved Data visibility and Decision-Making: With real-time data access, operators can make informed decisions, reducing downtime and optimizing production performance.

- Streamlined Operations and Reduced Errors: Automation of routine tasks through Ignition diminishes human error, resulting in consistent product quality and safety.

- Scalability and flexibility: Ignition’s robust platform allows seamless integration and expansion across multiple lines without disrupting existing operations.

- Cost Efficiency: By automating data collection and processing, Ignition reduces overhead costs and allocates resources more effectively.

We invite you to explore how these benefits can transform your production processes with Innorobix’s customized solutions. For a deeper dive into the integration possibilities or to request a consultation/demo,reach out to our team. Empower your production lines with ignition, and take the next step towards a smarter, more efficient food production environment.