Introduction

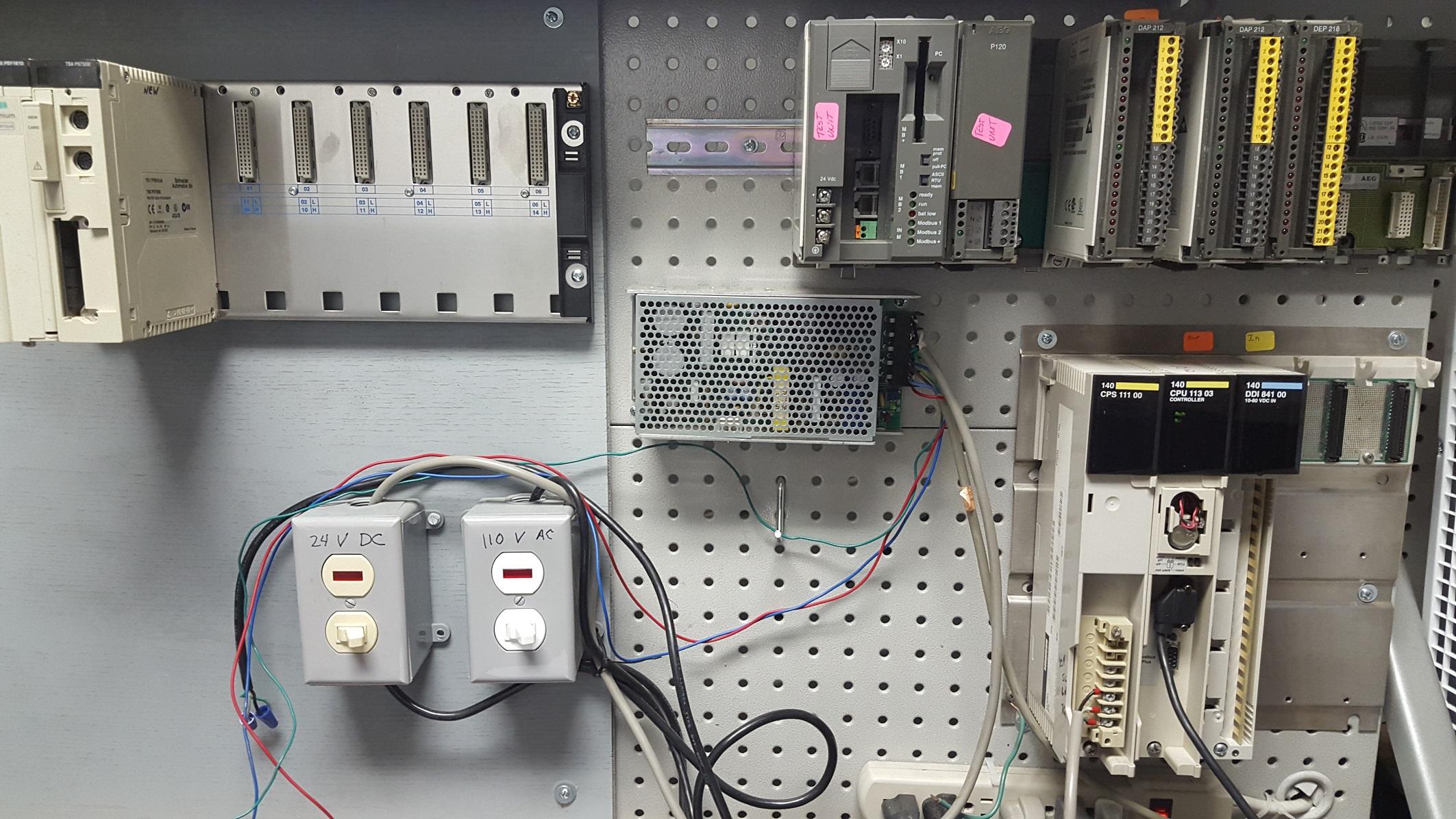

In the intricate landscape of the automotive industry, the integration of Programmable Logic Controllers (PLCs) and Manufacturing Execution Systems (MES) is a critical strategy for enhancing operational efficiency and ensuring seamless traceability. As automakers strive for greater productivity and quality in an increasingly competitive market, leveraging digital technologies becomes paramount. The convergence of PLC and MES technologies not only facilitates real-time monitoring and data analysis but also establishes a robust framework for traceability across the production cycle.

in this article, we will explore how this integration can propel automotive manufacturing to new heights by focusing on four key areas:

- Reducing Downtime: Automated alerts and real-time diagnostics enable quick responses to anomalies, minimizing production stoppages.

- Digitizing Traceability: By capturing every step of the production process, companies can assure compliance and improve accountability while harnessing data for continuous improvements.

- Standardizing PLC/HMI Across Lines: Uniform interfaces across different lines facilitate training, reduce errors, and streamline maintenance, enhancing operator efficiency and promoting a consistent user experience.

- Improving Overall Equipment Effectiveness (OEE): Advanced analytics and visualization empower manufacturers to identify bottlenecks, optimize processes, and drive better operational KPIs.

Real-World Examples

- Reducing Downtime: A major automotive manufacturer implemented Ignition to connect PLCs across multiple assembly lines. By utilizing real-time alerts for machine malfunctions,they reduced average downtime by 20%,substantially improving production flow.

- Digitizing Traceability: Ford Motor Company integrated their MES with PLC systems to log data on every part from production to the assembly line. This enabled them to quickly trace defective parts back to specific machines, reducing recall risks and improving quality assurance.

- Standardizing PLC/HMI: general Motors adopted a standardized PLC and HMI approach across its global manufacturing plants, allowing them to train employees efficiently while ensuring consistent operational parameters, thereby reducing training time by 30%.

- Improving OEE: Toyota implemented a extensive MES alongside their existing PLC frameworks, which allowed for real-time data analytics on equipment performance, leading to an increase in OEE from 75% to 88%.

as industries pivot towards smart manufacturing, the integration of PLC and MES systems emerges as a vital solution for achieving operational excellence. The following sections will delve deeper into the methodologies and technologies that facilitate this integration, providing actionable insights for automotive manufacturers looking to enhance their production ecosystems.

Maximizing Operational Efficiency Through Standardized PLC and HMI Interfaces

Standardizing PLC (Programmable Logic Controller) and HMI (Human Machine Interface) interfaces across multiple production lines is critical for maximizing operational efficiency in the automotive sector.A well-designed standardization approach reduces complexity, minimizes training time for operators, and ensures faster troubleshooting processes. As an example,consider an automotive manufacturing plant where multiple lines produce different vehicle models. By implementing a standardized PLC and HMI system utilizing Ignition, operators can easily switch between lines without extensive training, as the interface remains consistent. This not only streamlines the operation but also enhances the responsiveness of the workforce during maintenance and upgrades, ultimately reducing downtime.

Moreover, integrating these standardized systems with a Manufacturing Execution System (MES) allows real-time data monitoring and enables seamless traceability of components throughout the production process. This was showcased by a leading automotive OEM that adopted a unified approach where each vehicle’s production data, such as assembly time, quality checks, and component histories, are captured automatically via standardized interfaces.Notable benefits included:

- Enhanced visibility: Immediate access to data reduced instances of defects and quality issues.

- Informed decision-making: Data-driven insights lead to optimizing production schedules based on real-time performance metrics.

- Streamlined compliance: Easier tracking and documentation of traceability data for regulatory compliance.

This integration not only bolstered overall equipment effectiveness (OEE) but also positioned the plant as a leader in operational excellence, capable of meeting the high standards of the automotive market while minimizing costs.

Enhancing Real-Time Data Visibility for Improved Decision Making

Enhancing real-time data visibility in automotive manufacturing can significantly streamline operations and foster informed decision-making. With the implementation of Integrated PLC and MES systems,manufacturers can achieve instant access to critical data,enabling operators and managers to respond proactively to production challenges. For instance, when a fault occurs on the assembly line, operators can immediately identify the cause by accessing real-time data from PLCs, substantially reducing response times. This means that instead of experiencing lengthy downtimes while investigating issues, teams can pinpoint problems related to specific machinery, track the performance of individual line segments, and implement corrective actions without delay.

utilizing tools like Ignition by Inductive Automation and other MES solutions, manufacturers can also visualize key performance indicators (KPIs) and operational metrics on comprehensive dashboards. This allows not only for immediate visibility but also for long-term trend analysis. Consider an automotive plant that has integrated its PLC outputs with MES systems; they are now able to monitor the Overall Equipment Effectiveness (OEE) in real-time, which consists of availability, performance, and quality metrics. This enables teams to identify underperforming areas and facilitates standardized processes across multiple production lines, ultimately enhancing responsiveness to market demands and improving quality assurance protocols. By providing operators with clear insights,automotive manufacturers can ensure that each vehicle’s traceability is tightly linked to quality checks throughout the production process,creating a robust framework for product integrity and operational excellence.

Leveraging Ignition and MES Systems for Comprehensive Traceability

Implementing Ignition alongside a robust MES system unlocks unparalleled capabilities for comprehensive traceability within automotive manufacturing. As an example, consider a well-known automotive manufacturer that integrated these systems to enhance their quality assurance processes. By utilizing real-time data from PLCs, they are now able to track every component—from raw materials to finished products—throughout the entire production cycle. This level of monitoring allows them to maintain detailed logs of each vehicle’s assembly history, which can be readily accessed in case of quality audits or recalls. The integration ensures that data flows seamlessly between systems, which not only improves response times during production but also significantly reduces the chances of errors that could arise from manual tracking.

the real strength of linking Ignition with your MES lies in the ability to standardize processes and reporting across multiple lines, improving your organization’s overall efficiency. Such as, a facility that manufactures electrical systems for vehicles adopted these technologies and created a unified dashboard that visualizes production metrics across all lines. Key performance indicators (KPIs) such as cycle times, defect rates, and inventory levels are now displayed clearly. This standardization enables immediate identification of inconsistencies and allows for rapid corrective actions, effectively minimizing downtime. As a result, not only has the company enhanced traceability, but they have also significantly improved their Overall Equipment Effectiveness (OEE), aligning with industry best practices.

Implementing Predictive Analytics to Minimize Downtime in Automotive Production

Integrating predictive analytics into automotive production offers a transformative approach for reducing downtime. Utilizing advanced data collected from various sensors across production lines, predictive analytics enables manufacturers to forecast potential equipment failures before they occur. For example, Ford implemented a predictive maintenance system on their assembly lines, which relies on machine learning algorithms analyzing historical performance data and real-time sensor readings. This proactive approach allows them to schedule maintenance activities during non-peak periods, thereby minimizing production interruptions. By leveraging tools such as Ignition and an integrated MES, Ford enhances its ability to monitor equipment health indicators, ensuring that any anomaly is detected and acted upon swiftly, thereby sustaining a continuous operation.

In addition to predicting failures, predictive analytics empowers automotive manufacturers with insights that can drive operational efficiency. For instance, Toyota employed predictive models to analyze production workflows and equipment utilization.By collecting data from PLC and MES systems, they identified bottlenecks in their processes that led to excessive downtime.this analytical approach enabled them to implement a standardized response framework that includes proactive adjustments or faster reconfigurations on the production floor. As a result, they not only enhance their overall equipment effectiveness (OEE) but also build a culture of continuous improvement—reducing scrap, improving product quality, and enhancing compliance with traceability requirements. The synergetic relationship between predictive analytics and integrated systems ensures that automotive production continues to evolve, becoming smarter and more resilient.

In Retrospect

integrating PLC and MES systems is pivotal for achieving seamless traceability in the automotive sector, ultimately enhancing operational efficiency and product quality. Key takeaways from this discussion include:

- Reduction of Downtime: Real-time data monitoring allows for proactive maintenance, reducing unplanned downtime by up to 30% based on industry case studies.

- Enhanced Traceability: Digital tracking of components and processes ensures compliance with industry standards, as seen in manufacturers like BMW utilizing MES for end-to-end traceability.

- Standardization Across Lines: Implementing uniform PLC and HMI designs simplifies training and boosts productivity, with Ford successfully standardizing its production lines to maintain consistent quality.

- Improved OEE: By leveraging Ignition and MES systems, automotive manufacturers report up to a 20% increase in Overall Equipment Effectiveness (OEE) through meticulous performance analytics.

As the automotive industry advances towards greater automation and digitization, now is the time to harness these technologies to remain competitive. We invite you to explore tailored solutions with Innorobix, where our team of experts can assist you in implementing these systems effectively. Contact us today to request a consultation or demo and take the first step towards revolutionizing your manufacturing processes.