Introduction

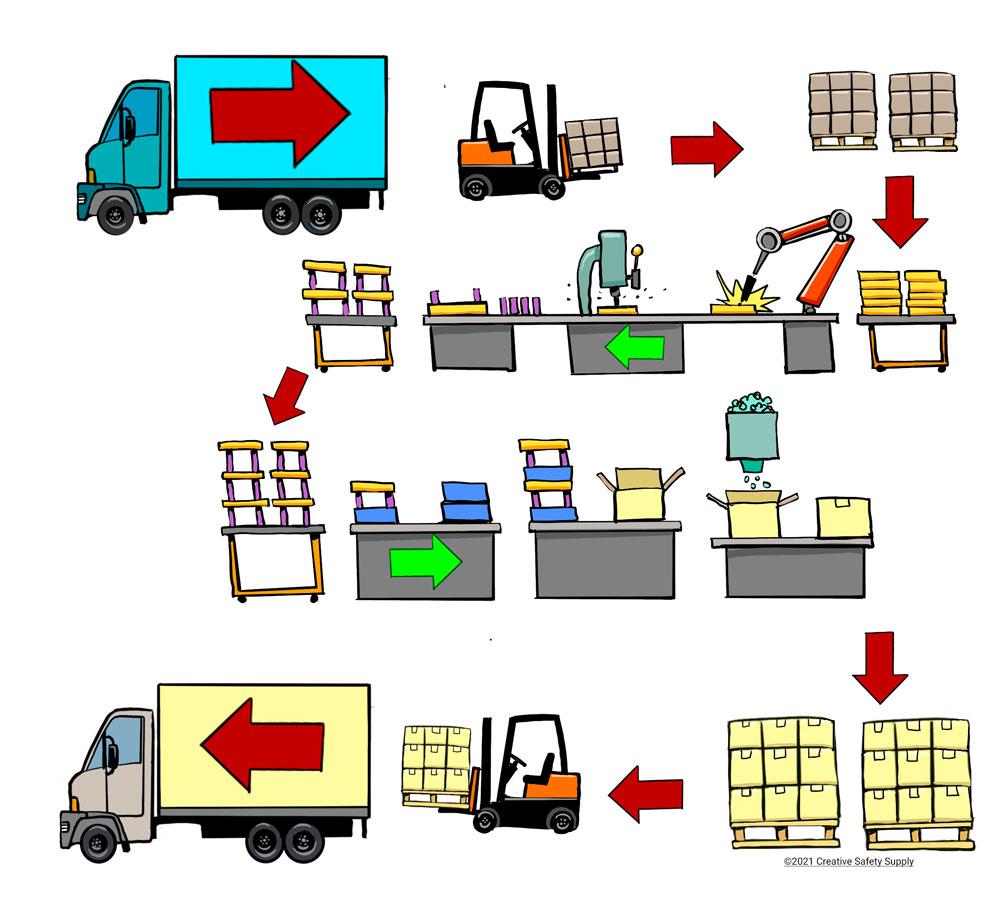

In the rapidly evolving landscape of the automotive manufacturing sector, optimizing material flow stands as a pivotal challenge and prospect. As manufacturers strive to enhance production efficiency and reduce costs, the integration of Autonomous mobile Robots (AMRs) and Programmable Logic Controllers (PLCs) emerges as a sophisticated solution. This technical discourse delves into the synchronization of AMRs and PLCs to streamline material handling, offering an authoritative guide to achieving operational excellence.

Why AMR and PLC Synchronization?

- Enhanced Automation and Flexibility: By integrating AMRs with PLCs, automotive production facilities can achieve a seamless material flow, reducing manual handling and increasing responsiveness to changes in production demands.

- Minimized Downtime: Proper synchronization between AMRs and PLCs allows for real-time adjustments in material transport, mitigating bottlenecks and ensuring continuous production.

- Boosted Efficiency and Throughput: Coordinated operation improves the precision and timeliness of material delivery, directly impacting production line efficiency and output.

Real-World Applications in Automotive Manufacturing

- Example 1: Just-In-Time (JIT) Delivery Systems: In a leading car manufacturing plant, AMRs synchronized with PLCs have revolutionized the JIT delivery of parts to assembly lines, drastically reducing wait times and excess inventory.

- Example 2: Dynamic Routing: A major automotive parts supplier utilizes AMRs guided by PLC inputs to dynamically adjust routes, avoiding congested paths and shortening delivery times, ensuring critical components arrive precisely when needed.

Key Considerations for implementation

- System Compatibility: Ensure AMRs are compatible with existing PLC infrastructure to facilitate seamless communication and coordination.

- Scalability and Modularity: Adopt solutions that can be scaled or modified in response to evolving production needs and capacities.

- Data Integration: Prioritize systems that enable robust data exchange between AMRs, PLCs, and overarching MES systems for improved decision-making.

In this article, we will explore the intricacies of AMR and PLC synchronization, analyzing technical nuances and providing actionable insights to empower automotive manufacturers in enhancing thier material flow processes. Through a comprehensive examination of real-world deployments and proven methodologies, this guide will serve as an indispensable resource for industry professionals seeking to harness the full potential of automated material handling solutions.

Optimizing workflow Efficiency through Advanced AMR Integration

Incorporating Advanced Mobile Robots (AMRs) into industrial settings presents transformative opportunities for workflow efficiency, particularly in synchronizing material flows with existing PLC-controlled processes. By integrating AMRs with PLC systems, automotive manufacturers can achieve real-time coordination that considerably streamlines operations. As an example, as parts reach specific dispatch points on the assembly line, a synchronized signal from the PLC can alert the AMR to deliver necessary components precisely when needed, minimizing downtime and eliminating bottlenecks. This synchronization is accomplished using Ignition and MES systems,which create a digital bridge between robots and the central control logic.Key benefits include:

- Reduced Material Handling Times: Automated conveyance directly to the point of use.

- Increased Flexibility: Swift adaptation to changes in production schedules and product variety.

- Improved Inventory Management: Real-time tracking and reduced stock levels.

- Minimized Human Error: automated systems with precise coordination.

Real-world examples, such as Tesla’s Gigafactory, demonstrate the power of AMR deployment when intrinsically linked with PLC systems. By integrating Autonomous Mobile Robots with Ignition-driven MES architectures, Tesla has redefined adaptability and efficiency in material handling. During peak production periods, AMRs efficiently reroute based on real-time data from PLCs, thus ensuring priority deliveries to areas with the greatest urgency. This responsive and agile methodology not only elevates production velocities but also enhances Overall equipment Effectiveness (OEE), as operations personnel can focus on system optimization rather than manual intervention. The synchronization between AMR and PLC forms the backbone for creating a nimble and resilient production environment that can swiftly respond to dynamic automotive manufacturing demands.

Leveraging PLC synchronization for Seamless Material Movement

- seamless Material Movement through Unified Protocols: The key to effective material movement within a modern automotive assembly line is the seamless synchronization of Automated Mobile Robots (AMRs) with Programmable Logic Controllers (PLCs). As a notable example, automating the delivery of just-in-time components directly to the production line requires precise communication among these systems. by leveraging industry-standard protocols like OPC UA, seamless data exchange can be achieved, enabling AMRs to interact and coordinate with PLCs in real-time. This synchronization ensures that when a PLC signals for a part replenishment, an AMR responds immediately, ensuring no production process is stalled. The impact is a continuous flow of materials, reducing bottlenecks, and enhancing overall production efficiency.

- Real-world Integration Scenarios: In practice, integrating amrs and PLCs has proven invaluable in reducing downtime and enhancing responsiveness.For example, an automotive plant might encounter frequent delays due to manual kitting processes which could be eliminated by deploying AMRs. These robots, equipped with sensors and synchronized with PLCs, navigate complex environments, delivering kits directly to the point of use. A real-world deployment at a leading car manufacturer’s facility demonstrated a 20% advancement in line efficiency after implementing synchronized AMR-PLC systems. Through this integration, manufacturers not only achieve substantial savings in labor costs but also significantly boost throughput, ensuring that production lines operate without interruption.

Insights into Real-World Automotive Applications of AMR and PLC

In the fast-paced world of automotive manufacturing, the synchronization of Autonomous Mobile robots (AMRs) and Programmable Logic Controllers (PLCs) is revolutionizing how materials are moved, tracked, and positioned. The seamless interaction between AMRs and PLC systems ensures a streamlined material flow, effectively reducing bottlenecks and increasing throughput. For instance, an automotive plant utilizing AMRs for just-in-time parts delivery is able to precisely coordinate their movement with existing PLC-controlled systems. This coordination is accomplished by using real-time data exchange facilitated through a unified communication protocol,ensuring AMRs deliver components exactly when needed during assembly,reducing wait times and idle periods on production lines.Real-world applications have shown notable advantages in aligning AMR capabilities with PLC systems. A prominent car manufacturer integrated AMRs equipped with sensors and IoT connectivity into their intralogistics. The AMRs communicate with PLCs to pick and deliver various components across several assembly stations. As they move, they automatically update their status and location in the PLC-managed system, allowing for dynamic routing and scheduling.This enables manufacturers to create an agile production environment, adaptable to changes in production schedules and demands, leading to enhanced production efficiency. Key benefits observed include:

- Increased flexibility to manage production changes in real-time.

- Reduction in manual handling of materials, which mitigates human error.

- Improved operational efficiency by maintaining precise inventory levels, reducing overproduction risks.

Recommended Strategies for Enhancing Material Flow and Reducing bottlenecks

Incorporating Automated Mobile Robots (AMRs) with synchronized Programmable Logic Controllers (PLCs) is a transformative strategy for enhancing material flow across automotive production lines. When AMRs are expertly integrated with PLC systems using advanced software protocols, they can dynamically respond to production needs, eliminating inefficiencies in material handling. As a notable example, consider a car manufacturing plant where AMRs equipped with real-time sensors and Bluetooth Low Energy (BLE) technology operate in harmony with PLCs to maneuver around moving machinery and workers. This precise synchronization mitigates risks of bottlenecks at critical junctures, such as assembly-line crossings, by ensuring that materials are delivered just-in-time, greatly enhancing line efficiency and safety.

Standardizing PLC interfaces and AMR fleet management offers additional layers of operational coherence and efficiency. Implementing an Ignition-based architecture allows for a unified platform where each AMR and PLC unit feeds real-time data into a centralized dashboard. This visibility enables operators to identify and rectify disruptions swiftly. benefits include:

- Seamless material handover between amrs and fixed stations, reducing waiting times.

- data-driven load balancing to optimize AMR dispatch sequences via MES systems,enhancing operational throughput.

- Predictive maintenance scheduling triggered by analytics from Ignition MES,minimizing unplanned downtime.

Such synchronization translates into improved Overall Equipment effectiveness (OEE) by ensuring a continuous flow of materials and consistent production output in the dynamic environment of an automotive assembly line.

Future Outlook

the synergy between Autonomous Mobile Robots (AMR) and Programmable Logic Controllers (PLC) heralds a new era of efficiency and precision in material flow management within the automotive industry. By seamlessly integrating these technologies, manufacturers can achieve remarkable improvements in operational efficiency, reduce bottlenecks, and ensure timely delivery of materials to the production lines. Key takeaways include:

- Enhanced Coordination: Synchronization of AMR with PLC systems leads to a streamlined material flow, minimizing idle times and enhancing production throughput.

- Increased Flexibility: The dynamic routing capabilities of amrs,coupled with PLC control,allow for quick adaptations to changing production schedules.

- Real-time Monitoring: Integrated systems provide real-time data and insights into material handling processes, enabling proactive decision-making and continuous improvements.

By adopting these methodologies, automotive manufacturers not only boost their competitiveness but also enhance their adaptability to Industry 4.0 standards. We invite you to explore these innovative solutions with Innorobix. Whether you’re looking to implement a new system or optimize your current setup, we offer tailored consultations and demonstrations to help you realize these advancements. reach out today to discover how our expertise can drive your operations forward.