Introduction: Navigating Regulatory Compliance with Ignition SCADA in Plastic Manufacturing

In the ever-evolving landscape of plastic manufacturing,regulatory compliance stands as a critical pillar for ensuring operational integrity,environmental responsibility,and consumer safety. As global standards become increasingly stringent, plastic plants face mounting pressure too meticulously manage and report operational data. Enter Ignition SCADA (Supervisory Control and Data Acquisition) – a comprehensive, cutting-edge solution that empowers facilities to efficiently monitor, control, and document processes in alignment with regulatory requirements.

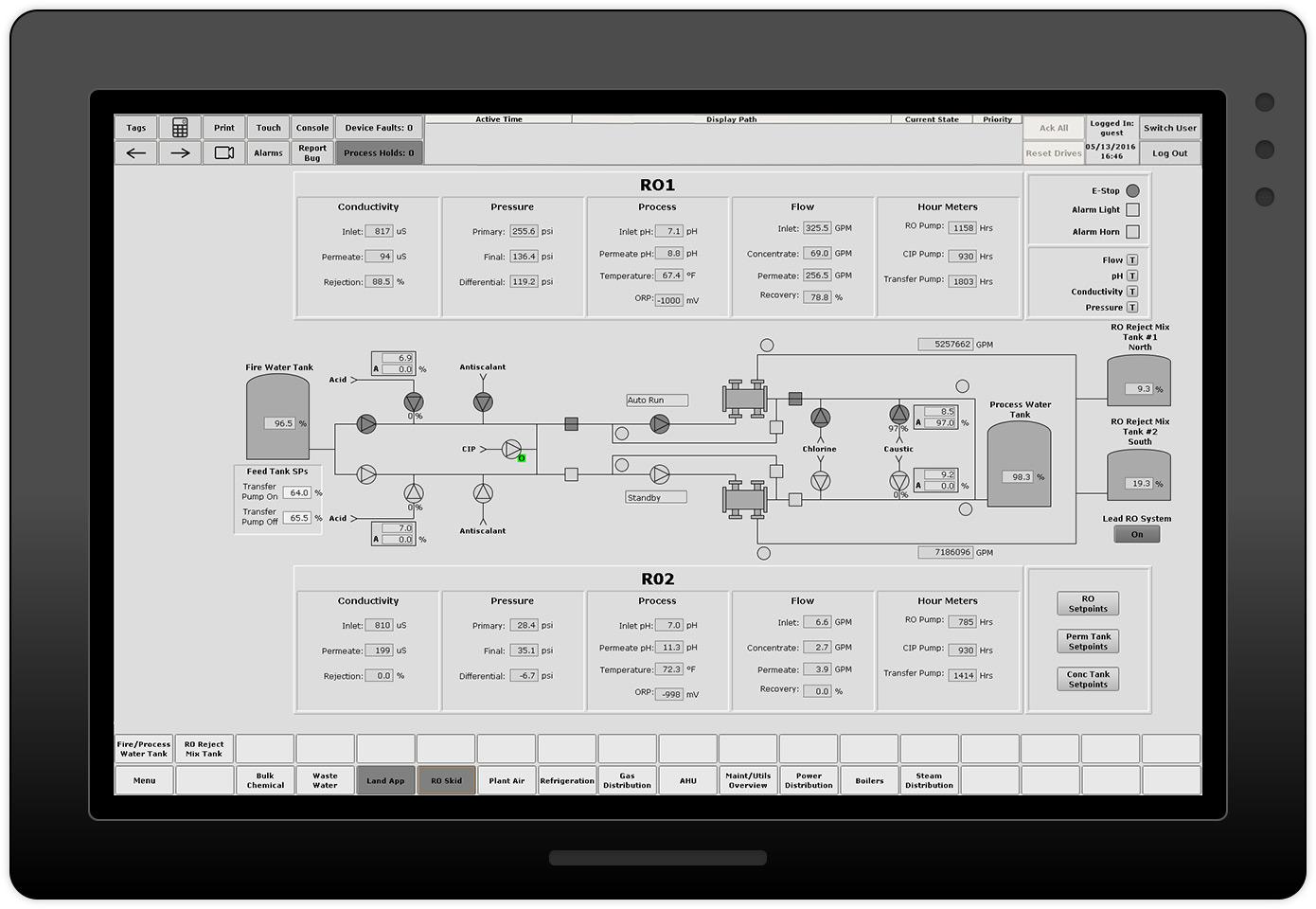

Ignition SCADA transforms the complex web of compliance into a streamlined, obvious, and manageable process. By harnessing its robust capabilities, plastic manufacturers can achieve and maintain compliance more effectively, while optimizing overall plant performance.Key areas where Ignition SCADA makes a substantial impact include:

- Real-Time data Monitoring and Reporting: Seamlessly track and record vital process parameters to ensure adherence to regulatory standards. for example, continuous monitoring of emission levels and waste disposal processes ensures environmental compliance with local and international standards.

- Automated Alerts and Notifications: Implement automated triggers and notifications for threshold breaches, enabling proactive management of potential compliance issues before thay escalate. This feature helps in maintaining consistent product quality and safety.

- Comprehensive Audit Trails: Generate detailed audit trails for processes and events, essential for regulatory reporting and inspections. This capability not only simplifies compliance audits but also enhances operational transparency and accountability.

- Scalable Integration with Existing Systems: Ignition SCADA offers seamless integration with a wide range of industrial control systems and databases, facilitating comprehensive data collection and management across all plant operations, nonetheless of scale.

Throughout this article,we will delve deeper into how Ignition SCADA serves as an indispensable ally in navigating the complex terrain of regulatory compliance in plastic manufacturing. Through practical examples and illustrative case studies, we’ll explore how this powerful tool not only aids in meeting today’s regulatory demands but also positions plastic plants as leaders in clean, efficient, and compliant production practices.

Real-time Monitoring and Reporting for Environmental Compliance

Employing Ignition SCADA in plastic manufacturing facilities allows for comprehensive real-time environmental monitoring. By integrating state-of-the-art sensors with PLCs (Programmable Logic Controllers), facilities can continuously track volatile organic compounds (VOCs), particulate matter, and other emissions directly from extrusion or injection molding equipment. This data is collected and analyzed instantly, enabling the facility to maintain emissions within the preset regulatory thresholds.Real-time data visualization within Ignition dashboards assists plant operators in making informed decisions to adjust processing parameters on-the-fly, ensuring compliance and minimizing potential fines.

Moreover, custom report generation features within Ignition support regulatory preparedness through ancient data documentation. Facilities benefit from automated data logging and customizable report templates that can be set to meet specific regulatory body requirements. For example, reports on emissions fluctuations over time provide invaluable insights for compliance audits. With strategic use of Ignition’s built-in notification system, alerts can be set up to notify plant engineers and environmental compliance teams via email or SMS when emission levels approach or exceed thresholds, promoting proactive rather than reactive environmental management strategies.

Integrating Ignition SCADA with Existing ERP Systems for Seamless Data synchronization

Integrating Ignition SCADA with existing ERP systems allows plastic plants to achieve seamless data synchronization, thus enhancing their ability to meet regulatory compliance requirements. By employing Ignition’s robust connectivity capabilities, facilities can bridge the gap between operational and business data environments.this real-time connection ensures that critical production data, such as material usage, batch tracking, and quality parameters, flow effortlessly into ERP systems like SAP or Oracle. Such as, if a plant utilizes an Ignition platform to monitor extrusion processes, the system can automatically log data points indicative of production anomalies directly into the ERP for immediate action. This level of synchronized data not only maintains adherence to governmental and industry standards but also supports a proactive approach to operational efficiencies.

From a compliance perspective, key advantages include:

- Improved Traceability: Automated data transfer ensures that every step of the production process is recorded, providing comprehensive traceability which is vital for compliance audits.

- Enhanced Reporting: By integrating Ignition with ERP systems, plants can generate detailed compliance reports quickly, aiding in quicker response to regulatory inquiries.

- consistency in Quality Control: The unified systems ensure real-time alerts and automated corrective actions for any compliance breaches,minimizing human error and enhancing product conformity.

These capabilities also contribute to environmental sustainability practices by reducing paper-based reporting and improving energy efficiency through better-aligned business operations.

Leveraging Predictive Analytics for Proactive Maintenance and Reduced Non-compliance Risks

In the rapidly evolving landscape of plastic manufacturing, ensuring regulatory compliance is paramount not only for legal and financial reasons but also for environmental stewardship. Predictive analytics, powered by ignition SCADA, plays a crucial role in this by enabling proactive maintenance strategies that considerably reduce non-compliance risks.For instance, consider a scenario where a pump failure could potentially lead to excess plastic waste. By integrating Ignition’s advanced data collection capabilities, manufacturers can monitor real-time data and apply machine learning algorithms to predict when equipment is likely to fail. This proactive approach allows for maintenance schedules that prevent such failures, thereby reducing waste and ensuring that operations remain within regulated waste limits.

The implementation of these predictive analytics frameworks within a factory setting provides several advantages. Firstly, it supports the seamless integration with existing PLCs and sensors without extensive rewiring, making the transition smooth and minimally disruptive. Secondly, Ignition enables the analysis of historical data to identify patterns that might indicate future non-compliance risks. For example, by examining temperature fluctuations in injection molding processes over time, manufacturers can identify trends that might lead to deviations from standardized specifications. Additionally,operators benefit from customizable alerts and reports that pinpoint potential compliance breaches before they occur,ensuring prompt corrective actions.This approach not only upholds environmental standards but also enhances operational efficiency and reduces the likelihood of costly regulatory fines.

Best Practices for Secure Data Management and Regulatory Reporting in Plastic Manufacturing

In the plastic manufacturing industry, secure data management and regulatory reporting can be complex yet vital tasks. Utilizing Ignition SCADA,plants can streamline these processes by ensuring that all relevant data is captured,stored,and reported efficiently.Data encryption is essential for protecting sensitive information, and Ignition facilitates this by integrating seamless encryption protocols within its data handling features. This not only meets industry standards but also mitigates risks associated with cyber threats. Furthermore, automating data backup using Ignition ensures that information is consistently preserved without manual intervention, minimizing the chance of data loss and aiding in maintaining compliance with regulations such as ISO 9001.

Ignition SCADA also empowers plastic plants by delivering compliance-ready reports through customizable templates. These templates can be adapted to various regulatory standards, such as the Restriction of Hazardous Substances (RoHS) Directive, ensuring that every facet of the manufacturing process is recorded and easily retrievable. By integrating real-time alarms and notifications,Ignition allows operators to react promptly to any compliance breaches,thereby maintaining operational integrity. Role-based access control within Ignition ensures that only authorized personnel can access critical data, further enhancing secure data management. By employing these practices, plastic manufacturers not only uphold regulatory compliance but also demonstrate a commitment to responsible and sustainable production methods.

The Way Forward

the integration of Ignition SCADA into plastic manufacturing operations emerges as a pivotal strategy for ensuring regulatory compliance and advancing operational efficiency. By leveraging ignition SCADA’s robust data acquisition capabilities and real-time monitoring, plastic plants can meticulously track and report critical parameters such as emissions, material usage, and energy consumption, thereby aligning with stringent regulatory requirements.Key takeaways include:

- Real-Time Monitoring: Continuous observation of production metrics to ensure compliance thresholds are consistently met.

- Automated Reporting: Streamlined data collection processes to generate precise and timely reports for regulatory bodies.

- Enhanced Traceability: Comprehensive tracking of materials and processes, fostering transparency and accountability.

- Energy Optimization: Insights into energy consumption patterns to promote sustainable practices and reduce environmental impact.

These capabilities not only facilitate adherence to regulations but also enhance process efficiency and sustainability. We invite you to explore how Innorobix, as a partner in innovation and compliance, can elevate your operations to new standards of excellence. Contact us today for a personalized consultation or to schedule a live demonstration,and discover how our solutions can be tailored to meet your compliance and operational goals.