In the rapidly advancing landscape of rubber and plastics manufacturing, maintaining a keen eye on process monitoring is paramount for ensuring both quality and efficiency. Ignition SCADA (Supervisory Control and Data Acquisition) emerges as a game-changing platform in this sector, offering unparalleled insights and control capabilities. This article delves into how Ignition SCADA enhances process monitoring in rubber and plastics plants, highlighting key functionalities and illustrating its impact through practical applications.

Ignition SCADA delivers a comprehensive suite of tools and features that cater too the diverse needs of manufacturing enterprises. Here’s a closer look at some of the ways it enhances process monitoring:

- Real-Time data Acquisition: Ignition SCADA facilitates seamless real-time data collection from various manufacturing processes, enabling operators to make informed decisions swiftly.

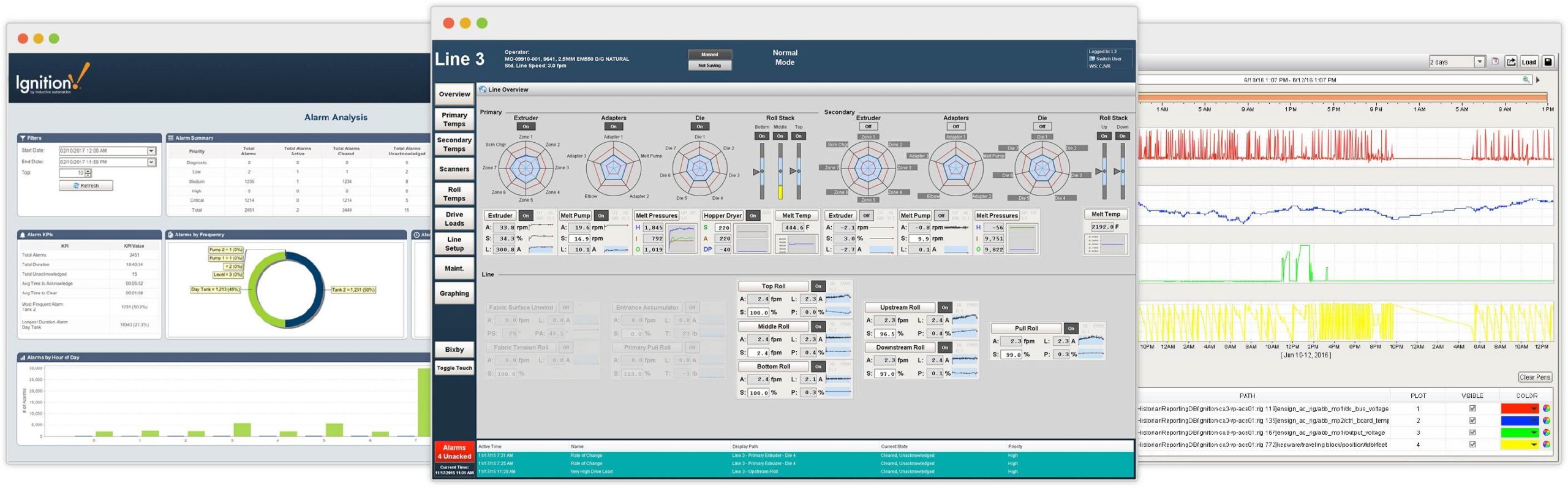

- Dashboard and Visualization: Wiht customizable dashboards, operators can visualize key performance metrics at a glance, enhancing situational awareness and fostering proactive interventions.

- Historical Data Analysis: By providing robust data logging and historical analysis, Ignition SCADA allows for trend recognition and long-term process optimization, which are crucial for maintaining consistent product quality.

- Alarm Management: Leveraging advanced alarm management functionalities, the platform ensures timely notifications and responses to critical process deviations, safeguarding operations from unplanned downtimes.

For example, consider its request in extrusion processes within a rubber plant. Ignition SCADA not only streams operational data in real-time but also utilizes predictive analytics to foresee potential disruptions in production,thereby reducing waste and energy consumption. Additionally, by integrating with existing PLC systems, it streamlines data flow and enhances interoperability, bridging the gap between automation hardware and enterprise systems.

Ignition SCADA stands as an authoritative solution for enhancing process monitoring in rubber and plastics plants. Its real-time data acquisition, coupled with comprehensive visualization and analytics tools, empowers manufacturers to refine their operations sustainably while minimizing energy usage and waste. As we explore further, the transformative impact of Ignition SCADA becomes increasingly evident across various facets of the manufacturing process.

Integrating Ignition SCADA for Comprehensive data Collection and Analysis in Rubber and plastics Plants

In the realm of modern rubber and plastics manufacturing, the ability to seamlessly integrate Ignition SCADA for extensive data collection and analysis has revolutionized plant operations. At its core, Ignition SCADA enables the capture and visualization of data from multiple sources, such as Programmable Logic Controllers (PLCs), sensors, and HMIs, across the plant floor. By doing so, it provides manufacturing engineers with the tools needed for real-time monitoring and decision-making. As an example, during the extrusion process in a rubber plant, Ignition SCADA can be configured to track critical parameters such as melt temperature, pressure, and screw speed. With comprehensive dashboards, operators can monitor these metrics and receive alerts when parameters deviate from set thresholds, ensuring high product quality and minimizing potential downtime.

Furthermore, Ignition’s ability to aggregate data for analysis enables advanced process optimization techniques. Plant managers can leverage historical data trends to identify inefficiencies, conduct root-cause analyses, and implement process improvements. Consider an injection molding plant facing inconsistent product weight issues; with Ignition SCADA, engineers can correlate machine cycle parameters to pinpoint the stage where variations occur. Additionally,by integrating energy monitoring systems,the platform can aid in identifying excessive energy use during peak operation periods,allowing for targeted energy-saving initiatives. utilizing Ignition’s extensive library of plugins and modules,plants can implement predictive maintenance strategies,such as machine learning algorithms for die wear detection,thereby extending equipment lifespan and reducing scrap rates. This holistic approach not only optimizes production efficiency but also supports clean tech initiatives by fostering sustainable manufacturing practices.

Real-time process Monitoring: Enhancing Operational Efficiency Through Ignition SCADA Dashboards

Utilizing Ignition’s SCADA dashboards in rubber and plastics plants considerably optimizes operations by providing real-time, comprehensive data visualization and process control.Operators are empowered with an interface that displays key performance indicators (KPIs) such as temperature, pressure, and flow rates on extrusion and injection molding machines. For instance, an extrusion process may require consistent monitoring of temperature across various zones; deviations can indicate potential issues or inefficiencies. A dashboard can showcase these parameters in real-time, allowing operators to swiftly adjust the process and maintain product quality. Additionally,real-time alerts can be configured to ensure immediate action when thresholds are breached,minimizing downtime and reducing waste.

The adaptability of Ignition’s approach allows seamless integration with existing Programmable Logic Controllers (PLCs), ensuring data from disparate systems is unified within the dashboard. This integration is vital for plants aiming to transition towards smart manufacturing. Imagine a plant equipped with energy monitors connected through PLCs, feeding data directly into Ignition. By monitoring energy usage per machine or process in real-time, plants can identify and address inefficient practices, contributing to a reduction in both operational costs and carbon footprint. this alignment with eco-pleasant practices not only supports sustainable production goals but also helps in maintaining competitiveness in the market.

Predictive Maintenance Strategies with Ignition SCADA: Reducing Downtime in Extrusion and Injection Molding

Incorporating predictive maintenance strategies using Ignition SCADA in extrusion and injection molding processes can significantly reduce equipment downtime and enhance operational efficiency. These strategies are primarily centered around real-time data collection and advanced analytics to predict potential equipment failures before they occur.By continuously monitoring key parameters such as temperature, pressure, vibration, and machine load, operators can identify anomalies that might indicate impending issues. As an example, consider a real-world example where an extrusion process might start exhibiting unusual vibration patterns detected by installed sensors. Through Ignition’s data analytics capabilities,this anomaly could trigger an alert,prompting a maintenance check that prevents a costly breakdown.

Implementing such predictive strategies involves a few essential components:

- Data Integration: Seamlessly connect various sensors and legacy systems to Ignition SCADA for a unified data flow.

- Machine Learning models: Utilize predictive algorithms within Ignition to analyze historical data and forecast potential failures.

- Real-Time Dashboards: Configure intuitive dashboards to visualize operational statuses and detect early signs of wear and tear in machinery.

- Automated Alerts: Set up automated notifications for key personnel when the data trends indicate abnormal conditions, enabling proactive maintenance actions.

These features not only facilitate timely intervention but also contribute to sustainable manufacturing by extending the lifespan of equipment and minimizing waste. By leveraging Ignition’s robust SCADA platform, plants can transition from reactive to predictive maintenance, aligning with modern clean tech practices that prioritize efficiency and environmental responsibility.

Improving Energy Efficiency and Sustainability in Rubber and Plastics Manufacturing with Ignition SCADA

Increasing energy efficiency is a critical concern in rubber and plastics manufacturing due to the intensive energy demands of processes like extrusion and injection molding. Ignition SCADA offers a comprehensive platform that seamlessly integrates with existing systems to monitor and optimize energy consumption. By using this system, plants can track real-time energy usage down to individual machines or production lines. The ability to visualize energy consumption patterns through dynamic dashboards enables operators to identify inefficiencies instantaneously. Such as, detecting unexpected spikes in energy consumption during non-peak hours can lead to timely interventions, such as scheduling predictive maintenance during these periods to enhance overall energy efficiency.

In addition to monitoring, Ignition connects with PLCs across the facility to enable data-driven decisions that propel sustainability initiatives. Through the use of energy consumption data, strategies such as load shifting or reducing machine idle times can be implemented to cut energy waste. Furthermore, the system’s capacity for remote monitoring allows operations teams to intelligently manage energy loads based on real-time analytics, leading to not only reduced energy costs but also minimizing the carbon footprint of the facility. With Ignition’s integration capabilities, manufacturers can deploy eco-friendly practices like using renewable energy sources to power specific processes without interrupting production, fostering a cleaner, more sustainable manufacturing surroundings.

To Wrap It Up

As we conclude our exploration of how Ignition SCADA enhances process monitoring in rubber and plastics plants, it is evident that this technology plays a critical role in driving operational excellence and sustainability. Key takeaways from this article include:

- Enhanced Process Control: Real-time monitoring and analytics that empower operators to swiftly address deviations and maintain optimal production levels.

- Predictive Maintenance: Utilizing machine learning algorithms to foresee equipment failures, thus mitigating unplanned downtime and extending machinery lifespan.

- Efficiency and Waste Reduction: Advanced tracking and optimization tools that facilitate notable reductions in energy consumption and material waste.

- Integration and Scalability: Seamlessly incorporating with existing infrastructure, allowing for future scalability and flexible adaptation to evolving technological needs.

By embracing Ignition SCADA, manufacturers not only improve efficiency and reliability but also contribute to a more sustainable future. at Innorobix, we specialize in crafting bespoke solutions that harness the full potential of this technology. We invite you to explore how our expertise can elevate your operations.Reach out to request a consultation or schedule a demo, and let us assist you in transforming your plant into a model of innovation and environmental responsibility.