Introduction: Harnessing Ignition in Automotive Manufacturing for Enhanced Shift-Level Production Tracking

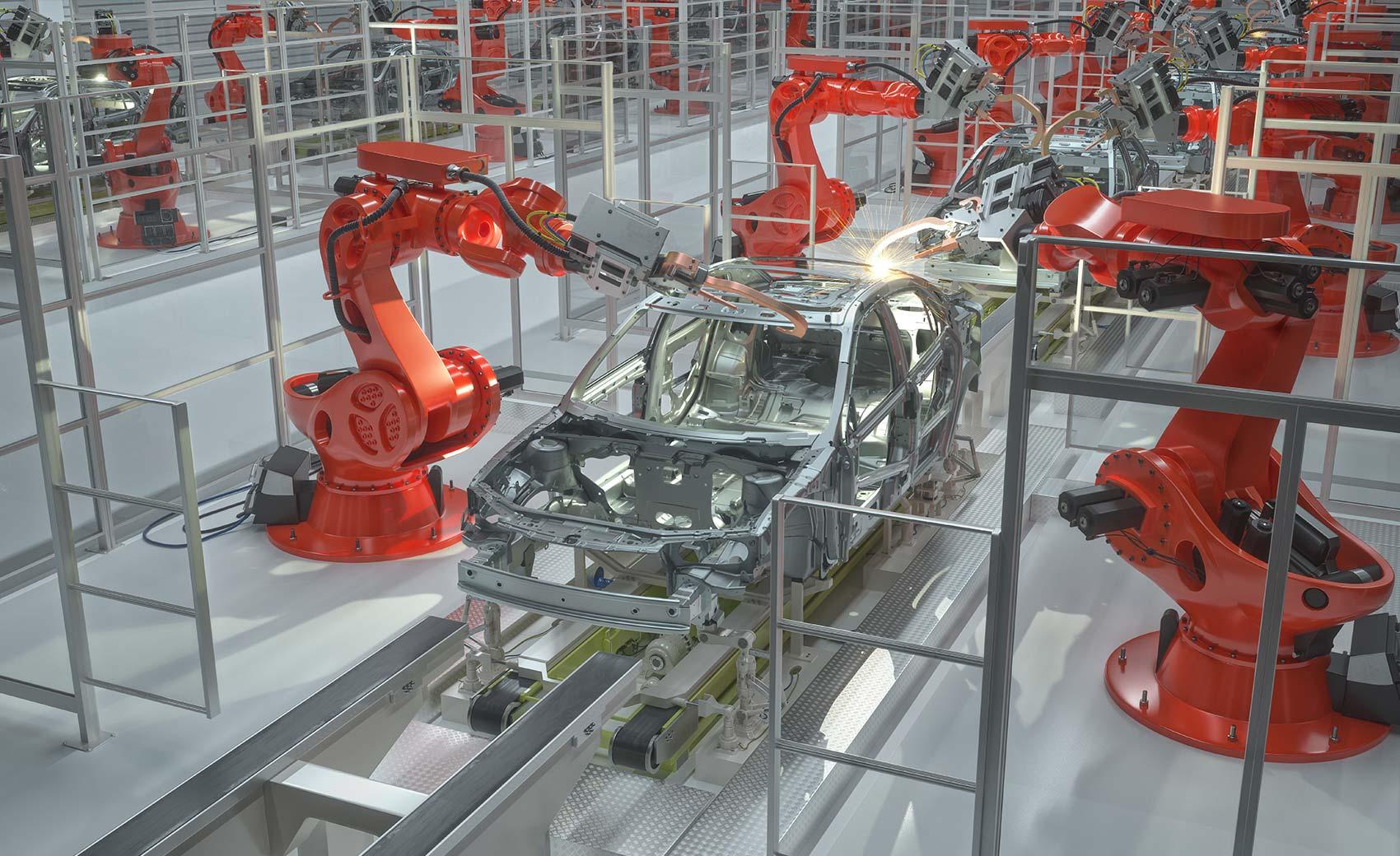

In the highly competitive and rapidly evolving automotive industry,maintaining precise control over production processes is crucial. Advanced digital tools are reshaping how automotive plants operate, providing manufacturers with the ability to track and adjust production targets at the shift level with unprecedented precision. Among these tools, Ignition by Inductive Automation stands out as a powerful integrative platform that enables seamless data acquisition, real-time monitoring, and actionable analytics.

This article delves into the transformative role of Ignition in automating and optimizing production tracking in automotive plants. By focusing on specific use cases, we illustrate how Ignition facilitates the management of shift-level production targets, offering tangible improvements in operational efficiency and output. Readers will gain authoritative insights into:

- Real-Time Data Integration: Learn how ignition integrates with existing plant floor machinery to collect real-time data, enabling operators to monitor progress against targets continuously.

- Improved Decision-Making: Discover how access to comprehensive, accurate data allows managers and supervisors to make informed decisions quickly, reducing delays and enhancing productivity.

- Role-Based Dashboards: Explore how customizable, role-based HMI dashboards provide operators, engineers, and managers with relevant data views, ensuring everyone is aligned with production goals.

- Case Examples: Analyze real-world applications in automotive manufacturing where Ignition has led to notable improvements in meeting and exceeding shift-level production objectives. One example involves a European automotive plant that utilized Ignition to reduce cycle times by 15% across key production lines by enhancing data visibility and leverage.

By integrating Ignition into their production processes, automotive manufacturers are not only achieving greater accuracy in tracking production targets but are also paving the way for enhanced operational excellence. This article serves as an insightful guide for industry professionals seeking to leverage digital technologies to elevate their manufacturing capabilities.

Tracking Real-Time Production Data with Ignition: Unlocking Efficiency in Automotive Manufacturing

In the competitive realm of automotive manufacturing,the ability to track real-time production data can distinguish industry leaders from the rest. Ignition software is enabling plants to seamlessly collect, visualize, and act on data across production lines, leading to unprecedented efficiencies. As a notable example, real-time dashboards created through Ignition provide operators with up-to-the-minute data on production targets versus actual output. This allows for immediate interventions if discrepancies arise, reducing downtime and ensuring that production goals are consistently met.By leveraging Ignition’s versatile data source connections,plants can integrate data from existing PLCs and sensors across the shop floor,making it easy to analyze performance and predict potential issues before they escalate.

Automotive giants such as Toyota have set benchmarks by utilizing Ignition’s capabilities to digitize each aspect of production. real-world applications include monitoring assembly line speed, tracking component usage, and even forecasting machine maintenance needs. With Ignition, plants can implement intelligent alert systems, which notify shift supervisors of any anomalies in production levels or equipment behavior. This proactive approach allows for quick adjustments that optimize operations,such as reallocating resources or scheduling maintenance downtime during low impact periods. Moreover, using Ignition’s robust reporting tools, manufacturers are equipped to deliver comprehensive shift reports that are crucial for Continuous Improvement (CI) initiatives. This ultimately enhances the plant’s Overall Equipment Effectiveness (OEE) by aligning shift-level targets with real-time execution and past performance data.

Enhancing Production Target Visualization: Utilizing Ignition’s Powerful HMI Dashboards

in the whirlwind pace of automotive manufacturing, having real-time visibility into production targets is critical. Ignition’s HMI dashboards empower production managers by providing dynamic, real-time data visualization of shift-level performance metrics. These dashboards are not only customizable but user-kind, allowing for streamlined integration with existing PLC systems across various production lines. For example, Toyota’s Georgetown assembly plant utilizes Ignition dashboards to visualize hourly output in comparison to targets. This enables floor managers to instantly identify bottlenecks and react to discrepancies promptly, ensuring that they can deploy resources effectively to maintain production flow and meet targets. By integrating these dashboards into their MES systems, they have substantially reduced response time to production issues, improved employee performance, and enhanced overall communication within teams.

Key benefits of implementing Ignition HMI dashboards in automotive manufacturing include:

- Real-Time Monitoring: immediate insights on production performance, allowing quick corrective actions during shifts.

- Data Integration: Seamlessly integrates with existing ERP and MES systems, providing a comprehensive view of production goals vs. actuals.

- Customizable Display: The ability to tailor dashboards to specific manufacturing lines or products for more targeted monitoring.

- Improved Worker Engagement: Workers receive instant feedback on their performance, fostering a culture of continuous improvement.

- Data-Driven Decisions: Facilitates informed decision-making by analyzing trends and deviations over time.

By leveraging Ignition’s advanced HMI capabilities, automotive plants can enhance operational efficiency and ensure a seamless flow from production lines to executive oversight.

Streamlining Shift-Level Production Reporting: Seamless Integration with MES systems

Integrating Ignition’s MES capabilities into automotive production processes allows for a detailed and cohesive approach to shift-level production reporting,addressing key challenges like real-time data retrieval and uniform reporting metrics across operations. By leveraging Ignition, operators and plant managers can access live data and historical reporting widgets that break down each shift’s performance against predefined targets. An example of this is Toyota’s utilization of Ignition to integrate their MES systems, which enables managers to gain insights into production efficiency, identify bottlenecks, and swiftly implement corrective measures. Through dashboards reflecting real-time key performance indicators (KPIs),managerial teams can compare shift outputs,track work-in-progress,and reconcile deviations promptly,ensuring that production targets are met consistently.

Utilizing Ignition further simplifies workflow by standardizing data collection and streamlining communication across all production levels. In a Ford facility, Ignition was instrumental in unifying disparate data sources, providing a transparent view of production statistics and allowing for seamless data integration with existing MES systems. This approach results in various benefits for automotive plants, including:

- accurate shift analysis through consistent data aggregation.

- Enhanced decision-making capabilities with visualized data tools.

- Reduction of manual entry errors by automating data capture.

- Improved cross-department collaboration via standardized reports.

By creating a reliable, digital ecosystem for monitoring shift-level production, companies can optimize their workflow, significantly improve operational efficiency, and ensure lasting productivity growth.

Best Practices for Implementing Ignition in Automotive Plants: Lessons from Industry Leaders

Integrate Seamless Data Collection: One of the paramount strategies for utilizing ignition effectively in automotive plants is to enhance data collection from the production floor.Companies like Toyota have successfully leveraged Ignition to automate real-time data aggregation from various production lines,ensuring consistency and accuracy in capturing shift-level production metrics. By deploying Ignition’s OPC UA capabilities, these plants connect to different PLCs and HMIs, seamlessly consolidating diverse datasets into a single pane of glass. This not only eliminates manual data entry errors but also provides a comprehensive overview of line performance, which is critical for meeting and exceeding production targets.

Enhance Real-time Monitoring and Analytics: Industry leaders like Ford optimally utilize Ignition’s real-time monitoring tools to track key performance indicators (KPIs) such as cycle time, downtime, and overall equipment effectiveness (OEE). With Ignition, they have crafted custom dashboards tailored to shift supervisors, giving them immediate insights into production variances. This approach facilitates quick decision-making, empowering teams to address issues like bottlenecks or machine faults on the spot. Embedding real-time alerts and analytics into these dashboards helps maintain a steady flow of production, aligning all shifts towards a unified goal of consistent output and quality.

In Conclusion

the integration of Ignition software in automotive plants has proven instrumental in effectively tracking production targets at the shift level, ensuring operational excellence and competitive advantage. By implementing Ignition, automotive manufacturers can achieve:

- real-Time Visibility: Access to live data that empowers teams to monitor and adjust operations swiftly.

- Enhanced Decision-Making: Analytics-driven insights that facilitate evidence-based strategies for output optimization.

- Streamlined Communication: Improved interaction between production teams and management through centralized dashboards.

- Efficiency Boosts: Reduction in downtime and increased overall equipment effectiveness (OEE) through proactive maintenance alerts.

These transformative advantages underscore the meaning of adopting cutting-edge MES solutions in the fast-paced automotive industry. To harness the full potential of Ignition and propel your facility towards superior productivity, we invite you to explore comprehensive solutions with Innorobix. Reach out to request a personalized consultation or to schedule a demo, and discover how we can tailor strategies to match your specific operational needs.