In the ever-evolving landscape of manufacturing and production,the integration of advanced technologies has reshaped the way businesses approach efficiency and accuracy. Among these innovations, the growth of part counter systems stands out as a pivotal advancement. Traditionally reliant on operator input, these systems often introduce the potential for human error and inefficiencies. However, a new frontier is emerging: the creation of part counter systems that operate autonomously, free from the constraints of human involvement. This article delves into the transformative potential of such systems, exploring the technologies that enable them, the benefits they offer, and the implications for the future of production environments. As we navigate this uncharted territory, we uncover not just a method for counting parts, but a glimpse into the future of smart manufacturing, where precision and reliability reign supreme.

Innovative Technologies for Automated Part Counting

the landscape of manufacturing is rapidly evolving with the advent of innovative technologies that enable automated part counting systems without the need for operator input.These systems harness the power of machine learning,computer vision,and IoT (Internet of Things) to enhance precision and efficiency in inventory management. By employing high-resolution cameras and advanced algorithms, these technologies not only ensure accurate part counting but also significantly reduce human error, leading to more reliable data throughout the supply chain.

Key features of these automated systems include:

- Real-time data processing: Instantaneous counting and tracking of parts as they move along the production line.

- Integration capabilities: Seamless connectivity with existing ERP systems for streamlined operations.

- Adaptive learning: Systems that evolve and improve their accuracy over time based on historical data analysis.

| Technology | Advantage |

|---|---|

| Machine Learning | Increases accuracy by learning from past data. |

| Computer Vision | Enhances object recognition for better counting. |

| IoT sensors | Allows for remote monitoring and data collection. |

By leveraging these cutting-edge technologies,businesses can not only achieve a higher level of operational efficiency but also foster a work environment free from the tedious,manual tasks typically associated with part counting. the move towards automation not only boosts productivity but also supports the agile manufacturing practices that modern businesses require to stay competitive.

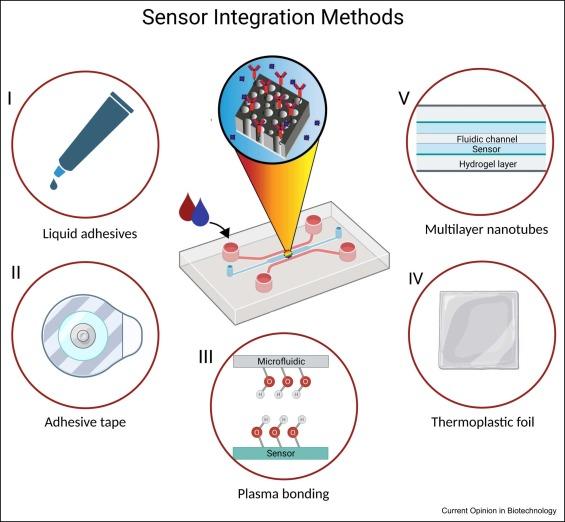

Enhancing Accuracy through Sensor Integration

Integrating multiple sensors into part counter systems significantly enhances accuracy by leveraging real-time data to track and verify every object passing through the system. By utilizing a combination of optical, ultrasonic, and laser sensors, these systems can create a comprehensive profile of each part’s physical characteristics, ensuring that no item is overlooked. The following technologies contribute to superior counting precision:

- Optical Sensors: Capture and analyze visual data to count parts based on size and shape.

- Ultrasonic Sensors: Measure distance and detect obstacles, enhancing the reliability of counts in variable environments.

- Laser Sensors: Provide high accuracy for counting fast-moving parts through precise measurement techniques.

The multi-sensor approach also allows for real-time feedback and error correction mechanisms.For instance,if a count discrepancy is detected,the system can perform automatic self-checks using the data from secondary sensors to validate the count. This seamless operation minimizes the risks of human error and ensures data integrity. The following table summarizes the benefits of sensor integration in part counting:

| Benefit | Description |

|---|---|

| Increased Efficiency | Reduces manual counting time and labor costs. |

| Improved Accuracy | Minimizes errors through continuous monitoring. |

| Real-time Data | Provides insights for instant decision-making. |

| Adaptability | Can be adjusted for various part sizes and types. |

Streamlining Data Management with Real-Time analytics

In today’s fast-paced manufacturing environment, creating part counter systems without direct operator input can significantly enhance efficiency and accuracy. By leveraging real-time analytics, companies can automate the tracking of components, utilizing cutting-edge technology like IoT sensors and machine learning algorithms. This not only minimizes human error but also delivers data instantaneously, allowing for swift decision-making and resource allocation. With an intuitive interface, operators can monitor system performance in real-time without the need for manual counting, leading to streamlined operations and less downtime.

Moreover, integrating these systems with existing enterprise software ensures that data flows seamlessly across platforms. This connectivity unlocks valuable insights through advanced analytics, enabling organizations to identify trends, optimize inventory, and forecast demand effectively. Consider implementing a dashboard that includes key performance indicators (KPIs) such as:

- Parts Count - Real-time count of parts produced.

- Error Rate – Tracking discrepancies in production.

- Operational Efficiency – Metrics on machine uptime versus downtime.

- Inventory Levels – Automated updates on stock status.

| Metric | Description | Importance |

|---|---|---|

| Real-Time Data | Immediate access to production metrics. | Enhances responsiveness in operations. |

| Predictive Maintainance | Utilizing data to foresee equipment failures. | Reduces unplanned downtime and repair costs. |

| Resource Utilization | Analyzing efficiency of materials used. | Optimizes supply chain and productivity. |

Best Practices for Implementation and Maintenance

Successfully implementing and maintaining a part counter system without operator input requires careful planning and execution. First, invest in reliable and accurate technology, such as advanced image recognition sensors or weight-based measurement systems, that can effectively automate the tracking process. Additionally, ensure that the software used to process this data is user-amiable and capable of integrating seamlessly with existing inventory management tools. By choosing the right mix of hardware and software, organizations can foster an environment that enhances accuracy and minimizes human error.

Moreover, once the system is in place, consistent monitoring and regular updates are essential to its durability and efficiency. consider these strategies for ongoing maintenance:

- Schedule routine calibration checks to ensure accuracy.

- Implement a feedback mechanism that allows the system to learn and adapt over time.

- Provide training for staff on how to troubleshoot minor issues without operator input.

- Establish a system for timely software updates to harness advancements in technology.

Having a dedicated team responsible for these tasks will ensure the longevity and reliability of the part counter system, enabling your operations to run smoothly.

Closing Remarks

the evolution of part counter systems that operate without the need for operator input marks a significant leap towards automation and efficiency in manufacturing and assembly environments. By harnessing innovative technologies such as computer vision, machine learning, and IoT capabilities, businesses can streamline their operations, reduce human error, and enhance productivity. As we forge ahead into an increasingly automated future, the insights shared in this article provide a valuable foundation for organizations looking to adopt these advanced systems. Embracing these methodologies not only paves the way for improved accuracy in inventory management but also frees valuable human resources for more complex tasks. As the industry continues to evolve, staying informed and adaptable will be key to leveraging these cutting-edge solutions effectively.The journey towards a fully automated, operator-free countering environment is not just a possibility—it’s on the horizon, waiting to be realized.