Introduction: Creating HMI Interfaces for Plastic Machine Operators Using Ignition Viewpoint

In the rapidly evolving landscape of plastic manufacturing, the integration of advanced technology and automation is paramount for enhancing operational efficiency and ensuring optimal product quality. Human-Machine Interfaces (HMIs) play a crucial role in bridging the gap between complex machinery and the human operators who oversee their performance. ignition Perspective, a cutting-edge tool provided by Inductive Automation, offers a revolutionary approach for developing dynamic, flexible, and user-friendly HMIs tailored specifically for plastic machine operators.

In this article, we will delve into the fundamental aspects of creating HMI interfaces using Ignition Perspective, elucidating its advantages and showcasing practical applications. The following sections will provide:

- Understanding Ignition Perspective: An overview of Ignition Perspective, highlighting its capabilities in developing web-based HMIs and its compatibility with various devices and operating systems.

- Benefits for Plastic Manufacturing: insight into how Ignition Perspective streamlines operations in plastic manufacturing, improving safety, efficiency, and responsiveness.

- key Features and Functionalities: Exploration of essential features such as responsive design, real-time data visualization, and ease of integration with existing PLC systems.

- Step-by-Step Example: A detailed, step-by-step guide on creating an HMI interface for plastic extrusion machine operators using Ignition Perspective, including best practices for layout, navigation, and data representation.

- Case Study Insights: Real-world examples demonstrating the impact of well-designed HMIs on production efficiency and operator performance in a plastic manufacturing environment.

By the end of this article, you will gain a thorough understanding of how to leverage Ignition Perspective to enhance HMI interfaces, providing plastic machine operators with the tools they need to efficiently and safely manage complex processes. Transforming the traditional approach to human-machine interaction, this innovative technology promises to redefine the standards of efficiency and precision in the plastic industry.

Design Principles for Effective HMI Interfaces in Ignition Perspective

In designing effective Human-Machine Interfaces (HMIs) for plastic machine operators using Ignition Perspective, clarity and usability are paramount. Operators need intuitive navigation to interact effectively with complex systems like extrusion and injection molding machines. Ensure that interfaces allow operators to quickly access the most critical machine parameters, such as temperature, pressure, and cycle time. By incorporating responsive design principles, HMIs can adapt to various screen sizes, enabling operators to efficiently monitor equipment from different devices, whether a desktop or a mobile tablet. Visual hierarchy should guide users naturally to essential data. Employ visual cues like color coding to indicate alarms—red for emergencies, yellow for warnings, and green for normal operations—benefitting instantaneous recognition.

Moreover, contextual data presentation is crucial, ensuring operators have the right information at the right time, promoting informed decisions and reducing reaction times. For instance, when overseeing an injection molding process, the interface might prominently display the shot size, mold temperature, and cycle count on the main dashboard while allowing drill-down capabilities for detailed diagnostics. Additionally, implementing trend graphs for process variables can facilitate predictive maintenance strategies by making patterns in data more perceptible.When designed with these principles, HMIs not only enhance operational efficiency but contribute to more enduring practices by reducing material waste and improving energy efficiency. Successfully integrating Ignition Perspective in this manner empowers operators to respond proactively to changes in machine performance, thus optimizing the entire plastic production cycle.

Customizing User Experience: Tailoring HMIs for Operator Efficiency

To maximize operator efficiency and satisfaction in plastic manufacturing environments,it’s essential to design Human-Machine Interfaces (HMIs) that cater specifically to their needs. Ignition Perspective offers an intuitive platform to enable this through its customizable widgets and responsive design. For instance, in an extrusion line, the interface could feature real-time machine status displays and allow for instant adjustments of critical parameters like temperature and pressure. by utilizing Ignition’s drag-and-drop functionality, operators can create custom dashboards with speedy-access buttons for frequently used commands, significantly reducing the time spent navigating through layers of menus and screens.Furthermore,multilingual support could be integrated into these HMIs,ensuring that operators from diverse backgrounds can engage with the system seamlessly,reducing the cognitive load and streamlining the workflow.

Consider incorporating data-driven alerts and visual cues that enable operators to preemptively address potential issues in the manufacturing line. Such as, color-coded indicators—green for normal operation, yellow for warning states, and red for critical alarms—can be employed to quickly relay crucial information. Additionally, implementing features such as drag-and-drop reordering of interface elements ensures that operators can personalize their HMI to reflect their particular workflow requirements, thus enhancing effectiveness and reducing response times. By fostering an environment where operators can collaboratively develop and enhance their interface, production lines become more adaptable and resilient to disruptions, promoting a clean tech approach by minimizing downtime and enhancing overall energy efficiency.

Advanced Visualization Techniques: Leveraging Ignitions powerful Tools

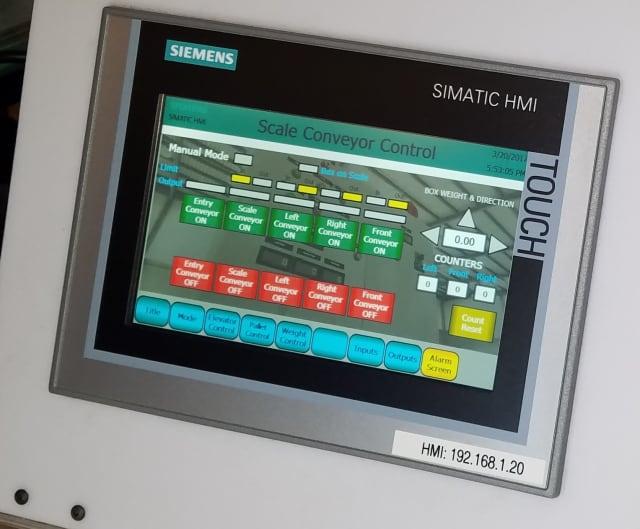

in the rapidly evolving field of modern manufacturing,the power of advanced visualization is indispensable in enhancing HMI interfaces for operators working with plastic machine systems. Ignition’s Perspective module offers a robust toolkit that seamlessly integrates with plcs to deliver real-time data and process visualization straight to operator dashboards. By using Ignition, operators at the extrusion line can view dynamic temperature control graphs, adjust pressure settings, and monitor the machine’s status without leaving their posts. This is achieved through custom dashboards that utilize drag-and-drop components such as LED indicators for machine status, sliders for real-time adjustment of variables, and interactive charts for tracking production metrics like throughput and yield rates.

Moreover, by leveraging Ignition’s support for HTML5, operators are no longer tethered to stationary control panels. Mobile-friendly interfaces through Perspective can be developed to give on-the-go access via tablets or smartphones, empowering operators with the versatility to oversee processes such as injection molding in real time nonetheless of their location on the site. consider a scenario where an operator gains immediate visual cues on scrap rates through color-coded bar graphs and can drill down into heat maps that signal areas of inefficiency, enabling quick decision-making and corrective action. This mix of data visualization not only improves operational efficiency but aligns with sustainable practices by reducing material waste and optimizing energy use, helping the enterprise to contribute to clean tech initiatives.

Best Practices for Integrating Real-time Data and Intuitive Controls

To seamlessly integrate real-time data into HMI interfaces, it’s crucial to establish a robust data architecture within the Ignition platform. Start by deploying a unified namespace that enables consistent data tagging and association.This approach allows plastic machine operators to access accurate, up-to-the-second information about processes such as extruder temperatures, injection cycle times, and material usage rates. For example, implementing MQTT for efficient data transport can enhance real-time responsiveness, enabling operators to make informed decisions promptly. Ensuring that the data structure supports scalability is essential, as production requirements often evolve. By doing so, you future-proof the system against changes and expansions, maintaining efficient data flows.

Intuitive controls are foundational to enhancing operator efficiency and safety on the production floor. Build HMI layouts that prioritize clarity and ease of use by employing visual aids such as color-coded alerts for temperature or pressure deviations, interactive charts for monitoring trends, and simplified navigation menus. Use Ignition Perspective’s responsive design capabilities to ensure that controls function seamlessly across devices, be it a wall-mounted terminal or a supervisor’s tablet. A practical example of this is utilizing drag-and-drop widgets to handle machine parameters, allowing operators to adjust settings intuitively without navigating complex panels. These practices not only contribute to a smoother workflow but also foster a safer environment by reducing the cognitive load on operators, enabling them to focus on critical tasks.

Wrapping Up

crafting effective HMI interfaces for plastic machine operators using Ignition Perspective not only enhances operational efficiency but also empowers workforce proficiency. By leveraging advanced features like responsive designs, real-time data visualization, and intuitive user interfaces, operators can make informed decisions, reducing downtime and maximizing productivity. Key takeaways from this exploration include:

– Designing for usability and accessibility to ensure operators can easily navigate and interact with the system.- Utilizing Ignition’s drag-and-drop tools to swiftly create dynamic,data-driven HMIs.

– Implementing responsive design principles to accommodate various device platforms.

– Integrating user feedback loops to continuously improve interface functionality.

Embrace these strategies to transform your plastic manufacturing processes. For those interested in seeing these solutions in action, we invite you to explore what we at Innorobix can offer. Whether you are looking to streamline your operations or enhance your current setups,reach out for a personalized consultation or a demo. Let us help you drive innovation in your manufacturing process with the power of Ignition and our tailored expertise.