Introduction: Transforming Shift Reporting with Ignition SCADA

In the highly dynamic and precision-driven world of manufacturing, effective dialog between shifts is paramount. Shift reports have long been the cornerstone of operational continuity, ensuring that critical facts is seamlessly relayed from one team to the next. Traditionally, this has involved handwritten notes, spreadsheets, or standalone software that often disconnects from real-time data—all of which can contribute to inefficiencies and communication gaps.

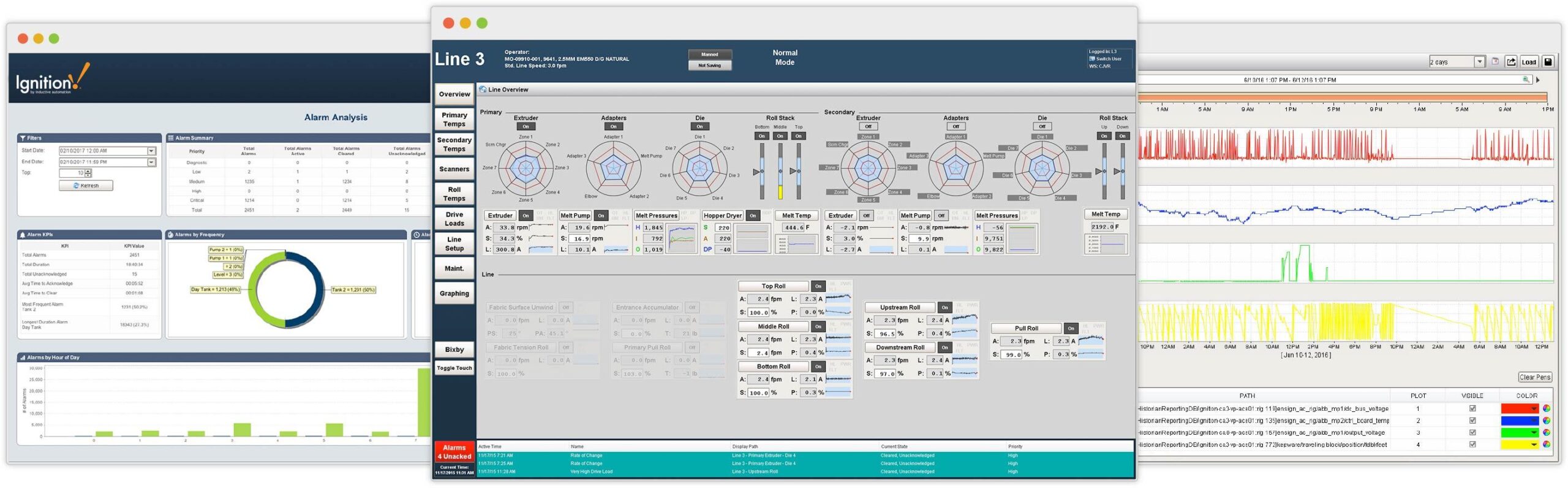

Enter Ignition SCADA (Supervisory Control and Data Acquisition) by inductive automation: a revolutionary platform that redefines the creation and management of digital shift reports. Ignition’s capability to merge real-time data visualization with robust historical analysis offers manufacturing facilities a transformative approach to shift reporting. Here’s how:

- integration with Live Data:

– Capture and integrate real-time data directly from PLCs (Programmable Logic Controllers) and other inputs.

– Automate data collection to ensure accuracy and reduce human error.

- Customizable Dashboards:

– Design intuitive dashboards that highlight key performance indicators (KPIs) specific to each shift.

– Empower managers with drag-and-drop features to tailor reports without extensive programming knowledge.

- Historical Data Analysis:

– Utilize Ignition’s powerful SQL database connectivity to analyze trends, identify patterns, and make informed decisions based on historical data.

– Leverage this data to predict issues before they occur, thus proactively enhancing productivity.

- Cross-Platform Accessibility:

– enable easy access to shift reports from any device—desktop, tablet, or smartphone—enhancing versatility and responsiveness.

- Sustainability Insights:

– Monitor energy consumption and machine performance metrics to identify areas for improvement, contributing to a smaller carbon footprint.

This article delves into the nuances of creating digital shift reports using Ignition SCADA. We will walk you through its setup, demonstrate its functionality with industry examples, and offer insights into maximizing its potential to foster a more connected, efficient, and environmentally conscious manufacturing environment. By the end of this article, you’ll grasp the full scope of how digital shift reports can bolster your operation’s communication and efficiency while aligning with enduring practices.

Understanding the Role of Ignition SCADA in Digital Shift Reporting

The integration of Ignition SCADA into digital shift reporting is revolutionizing how manufacturing facilities track, analyze, and optimize thier operations. Ignition SCADA serves as a centralized platform that collects real-time data from various sources across the production floor, such as Programmable Logic Controllers (PLCs), sensors, and databases. This real-time data collection is pivotal for creating accurate and thorough digital shift reports that detail performance metrics, process anomalies, and maintenance requirements. These reports are not just static documents; they are dynamic dashboards that evolve with every minute, providing insights that drive strategic decision-making and operational efficiency.

In a practical setting, imagine a plastics manufacturing plant where Ignition SCADA is configured to monitor and log data from extrusion machines. Here, critical data points like temperature, pressure, and throughput are analyzed in real-time. This data is then automatically populated into shift reports which can be viewed and customized through Ignition’s intuitive user interface. The inclusion of historical data, combined with real-time analytics and trend analysis, highlights deviations from normal operations and suggests proactive measures. The benefits are manifold, including:

- Enhanced actionable insights: Operators can now easily identify patterns of machine downtime and quality issues, helping in root cause analysis.

- Improved openness and accountability: Automatically generated reports ensure all stakeholders have access to the same information, reducing errors from manual entry.

- Fostering a culture of continuous improvement: Operators and managers are better equipped to optimize processes, minimizing waste and improving sustainability.

Design Best Practices for Effective Shift Report Templates with Ignition

When designing shift report templates with Ignition SCADA, it’s imperative to align with best practices that enhance clarity and efficiency. An effective template should serve as a comprehensive snapshot of the operational shifts, capturing critical data points and insights for both management and operational teams. Customizability is key — consider providing dropdown menus for time stamps, production batches, and quality check summaries to reduce manual entry errors and maintain uniformity. Utilizing drag-and-drop components in Ignition’s designer, create sections that include daily goals versus actual production metrics, downtime occurrences, and maintenance actions. Leveraging Ignition’s scripting capabilities, automate the integration of live data feeds into these templates, allowing for real-time status updates and reducing manually intensive tasks.

Consider the inclusion of visual indicators, such as color-coded alerts for deviations in production standards or energy consumption spikes, which can be instantly flagged for swift decision-making. For example,if your facility has a plastics extrusion line,a green indication could signify optimal extrusion pressures,whereas red could alert to pressure drops requiring attention. Integrate trending graphs for machine performance showcasing historical data trends versus current cycle metrics. These graphs can be further customized with Ignition’s powerful charting tools to display essential KPIs tracked over multiple shifts, offering immediate visual insight into operational efficiency. By representing data visually alongside critical textual reports, you empower shift supervisors and plant managers to make informed and sustainable operational choices. Establish these design principles early, allowing for a resilience-oriented approach that aligns with your organization’s clean technology aspirations.

Integrating Real-time Data and Historical Analysis for Comprehensive Reports

Embracing the modern age of industrial automation, Innorobix leverages Ignition SCADA to seamlessly integrate real-time data with historical analysis, offering a profound change in crafting digital shift reports. Through this integration, manufacturing teams can benefit from immediate data visibility, which empowers them to make timely decisions. An example can be seen in a 24/7 extrusion plant, where real-time data from PLCs monitors parameters like temperature and pressure, while historical data tracks trends and anomalies over weekly or monthly periods. this duo of data types enables engineers to identify inefficiencies such as inconsistent heating cycles far more proactively. The result is a comprehensive report that not only captures the instantaneous snapshot of operations but also offers a narrative of historical patterns, providing more extensive insights into performance and maintenance needs.

Moreover, the ability to compile this data into digital shift reports through Ignition provides several distinct advantages:

- Environmental Impact Reduction: by analyzing patterns over time, plants can optimize processes to reduce energy consumption.

- Enhanced Scrap reduction: historical analytics can uncover recurring defect trends linked to specific shifts or machinery, aiding targeted improvements.

- User-Amiable Dashboards: Customizable interfaces allow floor operators and managers alike to view pertinent data distilled into easy-to-understand visual formats.

- Proactive Maintenance Scheduling: by correlating historical wear data with real-time alerts, maintenance can be preemptive, reducing unplanned downtime.

These features exemplify the notable shifts towards smarter manufacturing and sustainability initiatives across sectors, supporting not only operational efficiency but also contributing to a cleaner technological footprint.

Recommendations for Optimizing Report Distribution and Access in Manufacturing Environments

To optimize report distribution and access in manufacturing environments using Ignition SCADA, it’s crucial to take advantage of its flexible delivery options and robust security protocols. Leveraging Ignition’s Reporting Module,users can design reports that can be automatically emailed to specific stakeholders or exported to network drives for easy access and archiving. Implement user roles and permissions systematically to ensure that only authorized personnel can view or modify these reports. As an example, floor managers might receive detailed operational reports daily, while C-suite executives might only need weekly summaries. Through utilizing Ignition’s template-driven design, you can streamline reports creation, ensuring consistency across all departments. Responsive designs allow these reports to be accessed via tablets, enhancing mobility and on-the-floor decision-making.

Deploying Ignition’s built-in web browser capabilities provides another layer of seamless accessibility. Reports can be viewed directly from any device with browser capability, eliminating the need for special software. Consider implementing push notifications for real-time alerting when new reports are available or if critical metrics warrant immediate attention. Encourage feedback loops with stakeholders to continually refine report content and distribution methods. Such as, invite production supervisors to provide input on report formats that would better track KPIs relevant to their shift performance. This iterative feedback can improve operational efficiency by ensuring that insights are timely, actionable, and aligned with organizational goals.integrating these strategies into your Ignition SCADA system can considerably enhance information flow, decision-making speed, and overall transparency in a production environment.

to Wrap It Up

implementing digital shift reports using Ignition SCADA offers transformative benefits to manufacturing operations,elevating both efficiency and accuracy in data handling. By adopting this digital approach, organizations can experience a significant reduction in manual errors, streamline communication across shifts, and enhance data visibility for informed decision-making. Key takeaways from our exploration include:

- Real-Time Data Aggregation: Seamlessly integrate real-time data from various PLCs and sensors for comprehensive shift reporting.

- Enhanced Customization: Tailor reports to meet specific operational needs, ensuring relevant information is highlighted.

- Automated Alerts and notifications: Set up automatic alerts to keep teams informed and responsive to critical changes.

- Sustainability Impact: Reduce paper waste and streamline your company’s workflow, promoting a greener, cleaner operation.

Empower your team with advanced digital tools by exploring how solutions from Innorobix can integrate seamlessly with your existing systems.Our expertise in Ignition SCADA ensures your transition to digital shift reports is smooth and efficient. Contact us today for a consultation or to schedule a demo that will showcase how we can enhance your operational excellence. let’s innovate together towards a more efficient and sustainable future.