Common automation Pitfalls in Legacy Press Lines: Navigating the Transition

In an era where efficiency and precision are paramount, the world of press manufacturing stands at a crossroads. As companies increasingly turn to automation to enhance productivity, many find themselves grappling with the complexities of integrating new technologies into legacy press lines. While the promise of streamlined operations and reduced labor costs is enticing, the path to automation is fraught with pitfalls that can undermine investments and disrupt workflows.From outdated machinery that struggles to communicate with modern software to workforce reluctance in adopting new practices, the challenges are as varied as they are significant. In this article, we will explore the common automation pitfalls that plague legacy press lines, providing insights and strategies to navigate this transformative yet tricky terrain.Understanding thes challenges is the first step toward a successful automation journey,ensuring that the future of printing is not just efficient,but also resilient.

Understanding Technical Limitations of Legacy Systems

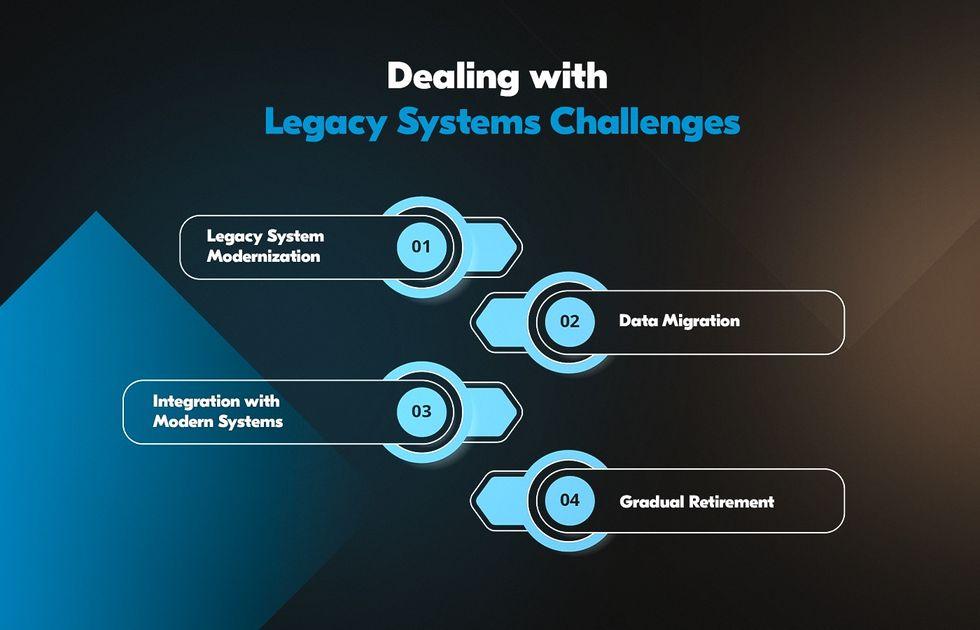

Legacy systems often serve as the backbone of industrial processes, but with age comes a set of inherent technical limitations that can obstruct the seamless integration of automation solutions. These systems were originally designed to function in a different technological era, leading to challenges such as outdated programming languages and hardware that lacks compatibility with modern tools. Common roadblocks include:

- Inflexible architectures: Many older systems lack modular design, making it arduous to implement changes or upgrades.

- data silos: Facts might potentially be trapped within discrete systems, preventing access to real-time data needed for effective automation.

- Performance bottlenecks: As demands on systems increase, legacy hardware may struggle to cope, leading to failures or slowdowns.

Moreover, the lack of documentation or skilled personnel familiar with these older technologies can further complicate efforts to upgrade. Attempts to automate processes rely heavily on robust communication protocols, yet many legacy systems use archaic methods that do not support modern networking standards. Key factors to consider include:

- Integration challenges: Legacy systems often resist integration due to incompatible interfaces.

- Maintenance issues: Repairing or updating older technology can be both costly and time-consuming.

- Regulatory compliance: Ensuring that legacy systems meet current industry regulations can become a daunting task.

Navigating Compatibility Challenges with Modern Automation Tools

Implementing modern automation tools within legacy press lines often leads to a myriad of compatibility challenges. These challenges stem from differences in technology,data formats,and communication protocols,creating a friction point that can slow down operations. Companies must recognize the importance of conducting thorough assessments of existing systems before integrating new technology. This should include an examination of:

- Current software capabilities and their ability to communicate with new tools.

- Equipment specifications to ensure seamless integration.

- Staff training needs to handle advanced systems.

to mitigate these issues, organizations should consider adopting a phased approach to automation. This allows for incremental upgrades that can be tested for compatibility and performance. Building a roadmap for integration is essential,enabling teams to identify critical touchpoints and potential bottlenecks. Establishing a feedback loop among technicians and operators can enhance the engineering outlook,ensuring that adjustments are made proactively. Below is a simple comparison of common integration strategies:

| Integration Strategy | advantages | Disadvantages |

|---|---|---|

| Full System Overhaul | Complete modernization, improved efficiency | High initial costs, significant downtime |

| Incremental upgrade | Lower costs, minimal disruption | Possible integration delays, legacy issues might linger |

| Hybrid Approach | Flexible adaptation, balanced investment | Complex integration management |

Enhancing Workforce Training for Seamless Integration

to ensure that your workforce is equipped to handle the complexities of modern automation systems in legacy press lines, a extensive training strategy is vital. This plan should focus on both the technical proficiency and adaptability of employees, addressing common pain points associated with automation pitfalls. Key elements of an effective training program may include:

- Hands-On workshops: Facilitate practical experience with the press line technologies,enabling workers to troubleshoot issues in real-time.

- Simulation Exercises: Develop scenarios that mimic potential automation failures, allowing teams to practice responses in a controlled environment.

- Upskilling Programs: Invest in ongoing education that embraces the latest automation trends and tools to keep your workforce competitive.

- Feedback Mechanisms: Implement regular assessments and encourage dialog about training efficacy, creating a culture of continuous advancement.

Beyond skill progress, fostering a culture of collaboration is essential for successful integration. Encouraging cross-departmental communication can help identify automation challenges that may not be instantly visible. Effective collaboration can manifest through:

- Inter-Departmental Teams: Form multidisciplinary groups that bring together various expertise to address automation-related issues holistically.

- Knowledge Sharing Sessions: Host regular meetings where personnel can share insights and lessons learned from automation experiences.

- Mentorship Opportunities: Pair seasoned employees with newer team members to facilitate knowledge transfer and build stronger relationships.

Implementing Proactive Maintenance Strategies for Long-Term Success

In today’s fast-paced manufacturing environment, legacy press lines must adapt and thrive by incorporating proactive maintenance strategies. One of the most common pitfalls is sticking to reactive maintenance, which often results in unexpected breakdowns and costly downtimes. To avoid this, organizations can implement regular maintenance schedules that include comprehensive inspections and upgrades to automation systems. Key components of these strategies might include:

- Routine Calibration: Ensuring all sensors and controls are functioning accurately.

- Predictive Analytics: Utilizing data-driven tools to forecast potential failures before they occur.

- Staff Training: Continuously educating personnel on the latest maintenance practices and technologies.

Moreover, integrating technology such as IoT devices into legacy systems can enhance monitoring and response capabilities. By creating a system where data is continuously collected and analyzed, companies can identify trends that point to equipment fatigue or inefficiency.A simple maintenance tracker can be extremely beneficial, offering insights such as:

| Maintenance Task | Frequency | Status |

|---|---|---|

| Oil Change | Monthly | Pending |

| Filter Replacement | Quarterly | Completed |

| Software Update | Biannually | Upcoming |

This structured approach not only drives efficiency but also fosters a culture of anticipation rather than reaction. By transitioning from customary methods to a more proactive maintenance framework, businesses can ensure their legacy press lines perform at their optimal capacity, ultimately paving the way for long-term success.

In Conclusion

As we conclude our exploration of common automation pitfalls in legacy press lines, it becomes clear that the path to seamless integration is paved with challenges that require careful navigation.Acknowledging these potential missteps is the first step towards transforming aging systems into robust, efficient operations. By prioritizing a thorough understanding of existing setups, fostering a culture of continuous learning, and investing in the right technologies, businesses can turn obstacles into opportunities.

The journey toward modernization may not be without its hurdles, but with awareness and diligence, the rewards can be significant. As you reflect on the insights shared, consider how you might approach your own automation strategy. remember, in the world of legacy systems, adaptation and foresight are key—embrace the challenge, and watch your press lines evolve for the better. The future of your operation awaits, and with the right approach, it can be as dynamic and responsive as the markets you serve.