In teh rapidly evolving landscape of manufacturing, the quest for efficiency and productivity often hinges on the ability to harness and analyze data from machines and processes. One of the unsung heroes of this endeavor is the spindle—a critical component in machining that directly influences the precision and quality of produced components. As the industry pushes towards greater automation and data-driven decision-making, understanding spindle load data becomes paramount.Enter MTConnect and Ignition: two powerful tools that together enable manufacturers to capture, visualize, and leverage spindle load data in real-time. This article delves into the intricacies of integrating MTConnect with Ignition, exploring how this dynamic duo can transform raw data into actionable insights, ultimately driving enhanced operational performance and innovation in modern manufacturing settings. Join us as we uncover the potential of this integration and its implications for the future of the industry.

Understanding the Significance of Spindle load Data in Manufacturing processes

Spindle load data is a crucial metric that offers insights into the operational efficiency of manufacturing processes. By analyzing this data, manufacturers can gain a deeper understanding of the performance of their machinery, leading to improved decision-making and enhanced productivity. Key benefits of tracking spindle load data include:

- Predictive Maintenance: Leveraging spindle load data can help in identifying trends that indicate potential failures before they disrupt production.

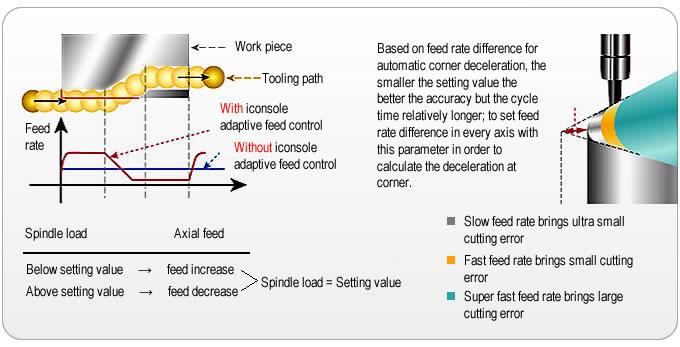

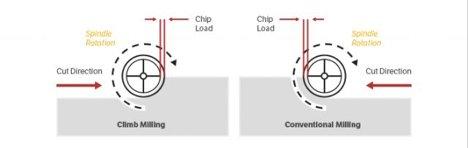

- Optimized Machining Parameters: Adjustments can be made based on load data to enhance cutting speeds and tool selection, ensuring optimal performance.

- Energy Efficiency: Understanding load patterns aids in energy consumption analysis, ultimately reducing manufacturing costs.

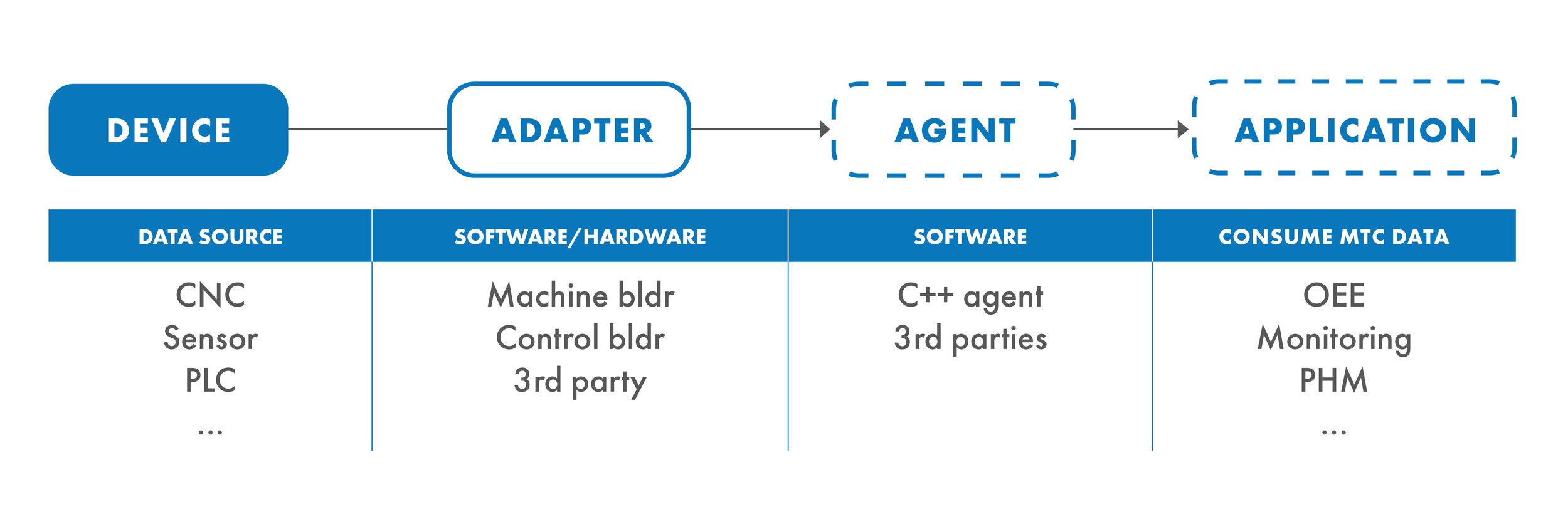

Furthermore, the integration of technologies such as MTConnect and Ignition plays a notable role in capturing and visualizing spindle load data effectively. The synergy of these technologies allows for:

- Real-time Monitoring: Continuous data streaming enables instant insights, allowing operators to respond swiftly to abnormalities.

- Data Visualization: Dynamic dashboards transform raw data into comprehensible visuals,assisting in speedy analysis and interpretation.

- Interoperability: MTConnect’s standards ensure seamless communication between machines and systems, optimizing data sharing across the shop floor.

Integrating MTConnect for Real-Time Data Acquisition and Monitoring

Integrating MTConnect into your manufacturing environment opens up a realm of opportunities for real-time data acquisition and monitoring.By leveraging this open standard, manufacturers can seamlessly capture critical spindle load data from CNC machines. This data is essential for understanding machine performance, optimizing operational efficiencies, and identifying potential maintenance issues before they escalate. Utilizing tools like Ignition alongside MTConnect enhances the visibility of this data, enabling operators to monitor spindle loads through intuitive dashboards and visualizations. Key benefits include:

- Improved Decision-Making: Real-time insights empower operators and managers to make informed decisions quickly.

- Predictive Maintenance: Identifying patterns in spindle load data can lead to proactive maintenance, reducing downtime.

- Enhanced Productivity: Continuous monitoring helps in fine-tuning machine settings, optimizing operational productivity.

To structure a seamless integration,a straightforward data model can be established. Below is a simple table illustrating the relationship between spindle load metrics and their impact on machine performance:

| Spindle Load Range (N) | Performance Indicator | Action Required |

|---|---|---|

| 0-50% | Underutilized | Increase Speed |

| 50-80% | Operating Normally | Monitor Conditions |

| 80-100% | risk of Overload | Evaluate and Reduce Load |

This framework not only aids in collecting real-time data but also fosters a culture of continuous improvement in the manufacturing process, ensuring machines operate at optimal levels while minimizing risks associated with overload conditions.

Leveraging Ignition for Enhanced Data visualization and Analysis

Incorporating Ignition into the workflow for capturing spindle load data through MTConnect opens up vast possibilities for effective data visualization and analysis. By utilizing Ignition’s powerful platform, users can create dynamic dashboards that provide real-time insights into spindle performance. With seamless integration, data from multiple machines can be collected and consolidated, enabling thorough monitoring and control. Here are some ways the platform enhances data handling:

- Real-time Monitoring: Instant access to spindle load metrics ensures immediate response to deviations in performance.

- Customizable Dashboards: Users can design tailored interfaces that highlight critical KPIs relevant to their operations.

- Advanced Analytics: Integrated tools allow for detailed analysis,facilitating predictive maintenance and optimization.

Moreover, Ignition simplifies the process of identifying trends and anomalies by visualizing data in intuitive formats. Users can utilize interactive graphs and charts to track spindle load data over time, making it easier to pin down issues and act proactively. To exemplify the impact of data visualization, consider the following table that outlines the key spindle performance indicators:

| Metric | Target Value | Current Value | Status |

|---|---|---|---|

| Average Spindle Load | 50% | 48% | Normal |

| Max Spindle Load | 80% | 76% | Normal |

| Load Variability | ±5% | ±4% | Stable |

With the combination of clear data portrayal and actionable insights, users can make informed decisions that drive efficiency and productivity in their operations.

Best Practices for Optimizing Spindle Performance through Data Insights

To achieve optimal spindle performance, harnessing the capabilities of data insights is essential. By integrating MTConnect with Ignition, manufacturers can collect real-time spindle load data that aids in monitoring and predictive analysis. This enables you to identify patterns and anomalies, empowering quick decision-making. To begin, focus on establishing a robust data collection framework by:

- Defining Key Performance Indicators (KPIs) that relate to spindle load and performance metrics.

- Implementing continuous data streaming to capture fluctuations in spindle load during operations.

- Utilizing visualization tools in Ignition to create dashboards that simplify data analysis.

In addition, consider performing regular data assessments to refine your strategy continually. This involves conducting scheduled reviews of spindle performance data to pinpoint inefficiencies,as well as assessing the effectiveness of any corrective measures taken.A useful approach involves creating a simple table to summarize spindle performance metrics from collected data:

| Metric | current Value | Target Value | Status |

|---|---|---|---|

| Spindle Load (%) | 85 | 75 | Above Target |

| Vibration Level (mm/s) | 1.2 | 1.0 | Caution |

| Run Time (hrs) | 120 | 100 | On Track |

By meticulously analyzing this data, organizations can anticipate maintenance needs and mitigate risks, ensuring that spindle performance operates at its peak efficiency.

Future Outlook

as we conclude our exploration of capturing spindle load data through the powerful combination of MTConnect and Ignition, it’s clear that the future of manufacturing is driven by innovation and connectivity. By harnessing the capabilities of data acquisition and real-time monitoring,organizations can gain invaluable insights into their operational efficiency and machine performance.This journey through the intricacies of spindle load measurement not only highlights the potential of advanced technologies but also emphasizes the importance of streamlined data integration in achieving optimal production environments. As manufacturers embrace these tools, they empower themselves to make informed decisions, enhance productivity, and ultimately pave the way for a more sustainable and responsive industry.

In a world where information is key,the ability to capture and analyze spindle load data with precision sets the stage for smarter manufacturing practices. As we look ahead, the ongoing developments in smart technology and data analytics promise to unlock even greater possibilities for operational excellence. Let us stay curious, open to learning, and ready to embrace the future of manufacturing that awaits us.