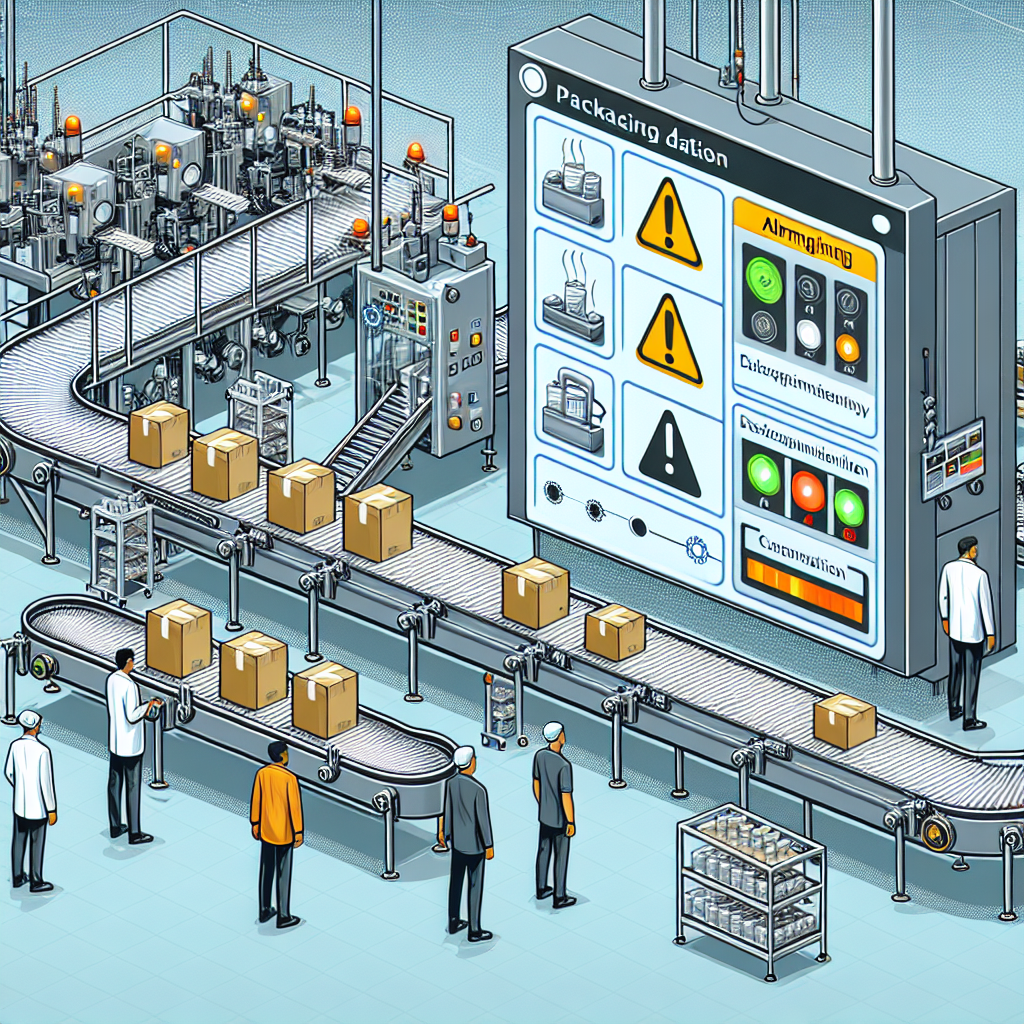

Alarm Notifications for Fill-Level Variations on Packaging Lines

In the packaging industry, maintaining consistent fill levels across product lines is critical for quality assurance, operational efficiency, and regulatory compliance. Variations in fill levels can led to several issues, including product waste, customer dissatisfaction, and financial losses. To mitigate these risks,implementing an effective alarm notification system is essential for monitoring fill-level variations in real-time. This article delves into the significance of alarm notifications, outlining their key components, and providing insights on optimizing fill-level management with the use of advanced automation technologies such as Ignition.

Key Considerations for Alarm Notifications:

- Real-time monitoring: Continuous tracking of fill levels enables immediate responses to deviations, reducing the time products spend out of specification.

- Automation Integration: By integrating alarm notifications with existing automation systems, facilities can centralize monitoring and streamline operations.

- User-Centric Design: Intuitive interfaces allow operators to quickly understand alerts and take appropriate action, minimizing human error.

- Data Analytics: Utilizing historical fill-level data for trend analysis can definitely help predict variations before they trigger alarms, enabling proactive quality management.

examples of Critical Alarm Scenarios:

- Underfill Notifications: Immediate alerts when a product is below the required fill level, prompting immediate corrective action to prevent packaging defective products.

- Overfill Alerts: Notifications when the fill exceeds predetermined limits, allowing for adjustments in real-time to avoid costly waste and maintain compliance.

- System Performance Anomalies: Alerts generated from sensor malfunctions or outages to ensure ongoing reliability of the filling equipment.

By establishing a robust alarm notification system for fill-level variations, packaging lines can enhance operational performance, safeguard product integrity, and substantially reduce the risk of non-compliance.In the following sections, we will explore the methodologies for implementing these systems effectively and how technologies like Ignition can elevate your packaging operations to new standards of excellence.

Understanding fill-Level Variations and Their Impact on Product Quality

Fill-level variations can severely compromise product quality, leading to significant operational setbacks. When packaging lines experience variations in fill levels,it often results in both under-filled and over-filled products. Under-filled containers may lead to customer dissatisfaction due to perceived value loss, while over-filled products can challenge packaging integrity and waste resources. As an example, a beverage company faced frequent fill-level inconsistencies that resulted in customer complaints regarding product shortages. By implementing a extensive alarm notification system, they were able to identify variations in real-time and adjust the filling apparatus on-the-fly, thereby reducing the acceptance of non-conforming products.

To tackle fill-level inconsistencies effectively, organizations can utilize advanced monitoring systems that trigger alarms based on predefined thresholds. This proactive approach not only enhances safety by minimizing the risk of improper fills but also increases traceability throughout the production process. Some critical elements to integrate into the alarm notification system include:

- Real-time monitoring: Continuous assessment of fill levels provides immediate feedback.

- Threshold settings: Customizable limits ensure that alarms are relevant and actionable.

- Data logging: Keeping a historical record of fill levels can help identify trends and root causes of variations.

- Automated adjustments: Smart filling machines can automatically correct the fill rate based on real-time feedback.

By incorporating these strategies, companies can significantly improve overall product quality while minimizing errors associated with human intervention. for example, a dairy manufacturer adopted this system and saw a 30% decrease in product rejections, thereby improving not only their bottom line but also their environmental footprint by reducing waste.

Real-time Monitoring Solutions for Accurate Fill-level assessment

Accurate fill-level assessment is critical in packaging lines, as even slight deviations can lead to significant product losses and regulatory issues. Implementing a real-time monitoring solution can definitely help mitigate these risks through continuous measurement and alerting systems. As a notable example, using pressure sensors combined with machine learning algorithms allows for the detection of inconsistencies in fill levels.If a sensor identifies that a bottle is under-filled or over-filled, an alarm notification can be instantly dispatched to the operators, ensuring immediate action can be taken. This is particularly important in industries like beverages, where exact volumes are mandated for compliance and consumer satisfaction.

Additionally, leveraging software solutions that integrate seamlessly with existing manufacturing systems can enhance traceability and safety. Beyond basic alerts, advanced platforms provide operators with real-time data analytics that facilitate informed decision-making. For example, visual dashboards can display trends in fill-level data over time, allowing quality control teams to identify persistent issues before they escalate. Implementing features such as automated logging of fill-level data,incident reporting,and audit trails ensures comprehensive documentation,significantly reducing the potential for human error. As seen in a recent case study involving a major food producer, adopting such technologies led to a 30% reduction in packaging line defects, ultimately improving both safety and product integrity.

Implementing Alarm Notifications: Best Practices and Technologies

Implementing effective alarm notifications for fill-level variations on packaging lines is crucial for minimizing downtime and maintaining product quality. To achieve this, it is essential to employ a combination of robust technologies and best practices.One of the most effective methods is to integrate an advanced monitoring system that leverages real-time data analytics. For example, using a Programmable Logic Controller (PLC) equipped with sensors to measure fill levels can provide immediate feedback. When a variation is detected that falls outside predefined thresholds, the system should automatically trigger an alarm notification through multiple channels, such as SMS, email, or real-time dashboard alerts.This not only enables rapid response to potential issues but also allows operators to take corrective action before significant problems arise, ultimately reducing product waste and labor costs.

Best practices for designing alarm notifications should focus on ensuring clarity and relevance of the alerts provided. Notifications must be specific, indicating the exact nature of the issue (e.g., “Fill level low on line 3, product A”) and suggesting actionable solutions. To enhance the effectiveness of these notifications, consider implementing a tiered alarm system that differentiates between critical and non-critical alerts. For instance, a slight fill-level variation might yield a visual alert on the control panel for immediate operator awareness, while a severe deviation could escalate to an audible alarm or direct notification to maintenance staff. Regular reviews and updates of alarm thresholds based on historical data and production goals can further optimize response strategies. By adopting such an approach, packaging lines can achieve higher operational efficiency and significantly reduce the risk of human error, thereby enhancing overall safety and accountability in production processes.

Enhancing Response Protocols to Minimize Downtime and Waste

In today’s fast-paced packaging environments,the ability to swiftly respond to alarm notifications stemming from fill-level variations is critical in mitigating both downtime and waste. Automated alarms can promptly alert operators and management when discrepancies occur, such as overfilling or underfilling products. As a notable example, a leading beverage manufacturer recently integrated an advanced alarm notification system capable of monitoring fill levels in real-time. Whenever the system detects an irregularity, it automatically categorizes the alarm based on severity and sends immediate notifications via email and text message to designated personnel. This kind of immediate dialog enables teams to respond within minutes, drastically reducing potential product loss and rework costs associated with filling errors.

Moreover, enhancing response protocols involves establishing a clear action plan for different levels of alarms. For each alarm type, protocols could include actions like checking sensor calibrations, inspecting fluid supplies, or conducting equipment maintenance. Here are key components for an effective response protocol:

- Tiered Alarm Levels: Classify alarms as low, medium, or high severity to prioritize response efforts.

- Automated Escalation: In the case of no response to an initial alarm, the system can escalate the notification to higher management.

- Historical Data analysis: Utilize data collected from previous alarms to train operators on frequent issues, allowing for preemptive action and reducing downtime.

By embedding these strategies into an association’s operational framework, companies can not only minimize product waste but also enhance overall safety and operational efficiency. By prioritizing rapid and structured responses,businesses are better equipped to ensure optimal performance on their packaging lines.

In Conclusion

the implementation of alarm notifications for fill-level variations on packaging lines is essential for enhancing operational efficiency and maintaining product quality. Key takeaways from this discussion include:

- Proactive Monitoring: By utilizing real-time alarm systems, manufacturers can identify fill-level disparities before they escalate into more significant production issues.

- Reduced Downtime: Prompt notifications facilitate swift corrective actions, minimizing unproductive downtime associated with packaging errors.

- improved Quality Assurance: Consistent fill-level monitoring ensures that products meet regulatory standards, ultimately boosting customer satisfaction and brand integrity.

As you consider optimizing your packaging operations, we invite you to explore innovative solutions with Innorobix, tailored to address the unique challenges of your production environment. For a hands-on experience or a personalized consultation, please request a demo, and let our experts guide you towards enhancing efficiency, safety, and compliance within your workflows.