Introduction to Predictive Maintenance in Food Processing: Harnessing SCADA and Sensor Data

In the dynamic landscape of food processing, ensuring operational efficiency while maintaining stringent quality standards is paramount. Predictive maintenance emerges as a transformative strategy that leverages complex technologies to anticipate equipment failures before they manifest, ensuring seamless production workflows. At the heart of this technological advancement lies the integration of Supervisory Control and Data Acquisition (SCADA) systems and cutting-edge sensor data analytics. This article delves into the critical role these technologies play in revolutionizing maintenance strategies within the food processing industry.

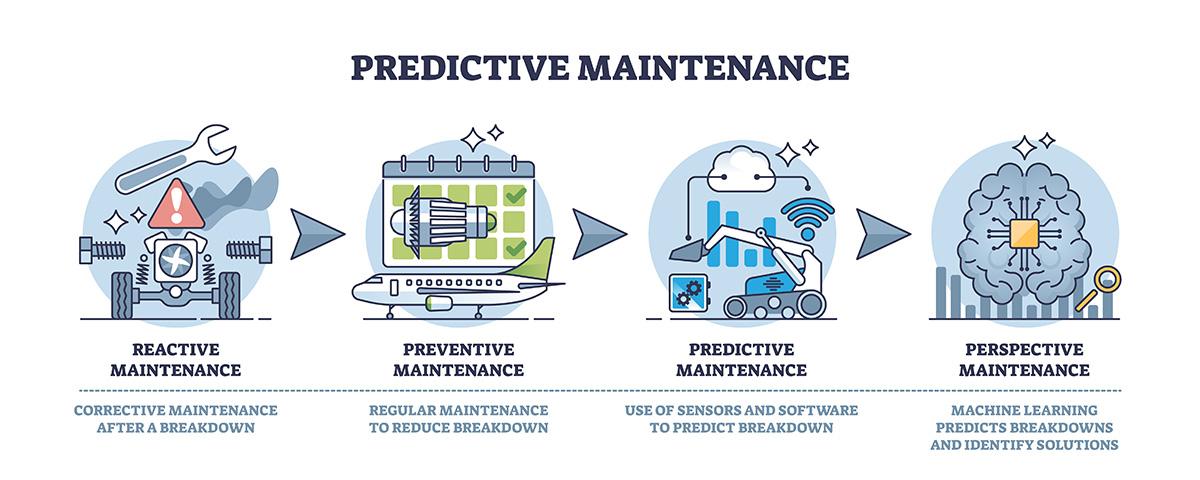

Predictive maintenance, unlike its reactive or preventive counterparts, focuses on real-time monitoring and data analysis to preemptively address potential equipment failures. This approach not only mitigates unplanned downtimes but also enhances the longevity and performance of critical machinery.

Key Benefits of Predictive Maintenance:

- Increased Equipment Uptime: By identifying and addressing issues before they lead to failures, food processing plants can maximize operational uptime.

- Cost Savings: Transitioning from reactive repairs to predictive strategies can significantly reduce maintenance costs, providing a compelling return on investment.

- Safety enhancement: Proactively managing equipment health contributes to a safer working surroundings, reducing the risk of accidents attributed to equipment malfunction.

- Quality Assurance: consistent equipment performance ensures product quality, critical in maintaining compliance with industry standards and regulations.

Incorporating SCADA systems offers a centralized platform for data acquisition and control,facilitating seamless interaction between operators and machinery. SCADA systems, coupled with an array of strategically placed sensors, gather vital data on equipment performance parameters such as temperature, vibration, and pressure. By employing algorithms and machine learning models, this data is transformed into actionable insights, enabling maintenance teams to predict and promptly address potential issues.

Practical Examples:

- Vibration Analysis: Sensors detect abnormal vibration patterns in conveyor belts,alerting technicians to possible misalignments or bearing failures.

- Temperature and Pressure Monitoring: Continuous observation of these vital parameters in ovens and refrigeration units helps maintain optimal processing conditions, preventing product spoilage.

As the food processing industry navigates the challenges of meeting rising consumer demands and stringent regulations, adopting predictive maintenance with SCADA and sensor data is not merely favorable but essential. This strategic shift promises to enhance productivity, profitability, and sustainability across the sector. Join us as we explore the intricacies and implementation strategies of predictive maintenance, delineating how it can serve as a cornerstone for future-ready food processing facilities.

Understanding the Role of SCADA in Predictive maintenance: Insights into System Integration and Data Flow

In the realm of predictive maintenance, Supervisory Control and Data Acquisition (SCADA) systems play a pivotal role by seamlessly integrating with various sensors and devices within food processing facilities. SCADA systems collect and analyze a wealth of data in real-time, enabling operators to gain insights into equipment health and predict potential failures before they occur. This integration is crucial for a continuous flow of data that supports maintenance strategies aimed at improving plant efficiency and reducing downtime. System integration through SCADA involves understanding multiple data points from different types of sensors,such as vibration,temperature,and pressure sensors,which can be placed on critical machinery like mixers and conveyors. A real-world example can be found in the monitoring of industrial ovens in bakeries. SCADA systems can analyze temperature fluctuations or abnormal humidity levels, enabling maintenance teams to act proactively to prevent yield loss.

When discussing data flow, it’s essential to recognize how SCADA systems channel and prioritize the influx of sensor data. Predictive maintenance relies heavily on this structured data flow to create actionable insights.Key data flows include:

- Data Acquisition: capturing raw data from various sensors installed on food processing equipment.

- Data Processing: Using SCADA’s computational power to validate,cleanse,and analyze the captured data for meaningful indicators.

- Data Visualization: Generating intuitive dashboards for operators to monitor equipment status and health effectively.

- Alert Management: Providing timely notifications and alerts when pre-defined thresholds are exceeded, allowing maintenance teams to respond promptly.

This structured data flow** model ensures that actionable insights are readily available, promoting data-driven decision-making, and minimizing the risk of unexpected equipment failures, thus improving both safety and productivity within the food processing industry.

Leveraging Sensor Data to Predict Equipment Failures: Techniques and Best Practices for Accurate Prognosis

In the world of food processing,accurately predicting equipment failures not only safeguards against costly downtime but also ensures product quality and safety. By leveraging sensor data within SCADA systems, food processors can gain actionable insights into the health of their equipment. The use of vibration analysis, temperature monitoring, and ultrasonic sensors collectively contribute to a predictive maintenance framework. As a notable example, vibration sensors deployed on mixers can alert operators when abnormal frequencies are detected, indicating potential mechanical faults. Similarly, temperature sensors on refrigerated storage units can predict cooling system failures before they affect product safety, ensuring compliance with stringent food safety regulations.

to get the most out of sensor data, it’s crucial to adhere to best practices in data collection and analysis. First, ensure sensors are calibrated correctly and maintained regularly to deliver precise readings. Second, integrate a robust data processing algorithm capable of distinguishing between false positives and genuine warnings. For instance, implementing machine learning models that analyze historical data to identify patterns indicative of failure can significantly improve predictive accuracy. real-time monitoring and visualization of sensor data through intuitive dashboards allow immediate action, minimizing human error and enhancing overall plant safety. By employing these techniques, food processors can effectively transform raw sensor data into a strategic tool for maintaining optimal plant health.

Implementing Predictive Maintenance Strategies: Practical Recommendations for food Processing Facilities

In food processing facilities,implementing effective predictive maintenance strategies involves leveraging SCADA systems and sensor data to anticipate equipment failures and optimize operations. The integration of vibration analysis, temperature monitoring, and power usage analytics through IoT sensors can provide a complete overview of machinery health. SCADA systems act as the central nervous system, collecting and analyzing data in real-time to provide actionable insights. As an example, a meat processing plant in Iowa utilized SCADA-connected vibration sensors to detect early signs of wear in their conveyor belts, allowing timely maintenance that prevented costly unplanned downtime. To replicate such a strategy, facilities should consider employing a few key components:

- Deploy multi-sensor arrays: Utilize a combination of vibration, temperature, and acoustic sensors to gain a holistic view of equipment health.

- Integrate predictive algorithms: Implement machine learning models within the SCADA architecture for analyzing historical and real-time data to forecast potential failures.

- Establish alert thresholds: Define specific metrics that, when breached, trigger automated alerts to maintenance teams, ensuring swift action.

Building a predictive maintenance framework not only boosts operational efficiency but also adheres to food safety compliance by maintaining optimal equipment performance. For example, a dairy processing facility in Germany successfully reduced unscheduled downtimes by 30% after deploying SCADA-based predictive maintenance, which included monitoring pasteurization equipment for temperature fluctuations and mechanical stress. The automation of data collection and analysis means less reliance on manual checks, thereby reducing human error and enhancing safety protocols. Adopting these automated approaches ensures a reliable production schedule while maintaining stringent hygiene standards crucial for food safety.

Best Practices for Safety and Compliance: Ensuring food Quality through Effective Maintenance Planning

in food processing facilities, employing predictive maintenance strategies is essential to ensure both safety and compliance, ultimately maintaining high food quality standards. The use of SCADA (Supervisory Control and Data Acquisition) systems combined with sensor data allows facilities to anticipate machine failures and schedule maintenance proactively. For instance,sensors can monitor vibration levels in machinery,providing data that can predict potential equipment failures before they occur,thereby reducing unexpected downtimes. A case in point is a dairy processing plant that employs temperature and pressure sensors within pasteurizers to safeguard against microbial risks, ensuring both regulatory compliance and consumer safety. By analyzing real-time data, these plants can maintain optimal operating conditions, reducing human error and enhancing the traceability of maintenance actions.To foster a culture of safety and compliance, facilities should incorporate a routine review and update mechanism within their predictive maintenance programs. This involves:

- Regularly calibrating sensors to ensure accuracy.

- Training staff to interpret SCADA data correctly and respond to alerts.

- Implementing automated maintenance logs to track and verify compliance efforts.

- Establishing a feedback loop to continually refine maintenance schedules based on insights from past equipment performance.

By adhering to these best practices, food processors enhance equipment efficiency and reliability, minimize the risk of contamination events, and uphold stringent industry standards—all of which collectively fortify the plant’s reputation and consumer trust.

To Conclude

predictive maintenance in food processing,powered by SCADA systems and sensor data,marks a transformative advancement in ensuring operational excellence. By leveraging real-time monitoring, data analytics, and machine learning, food processing facilities can anticipate equipment failures, optimize maintenance schedules, and reduce downtime, leading to improved production efficiency and safety. Key takeaways include:

- Enhanced Equipment Lifespan: Implement predictive analytics to accurately predict mechanical failures and prevent premature equipment wear.

- Increased Safety and Compliance: ensure regulatory compliance and workplace safety by maintaining equipment in optimal working condition.

- Cost Efficiency: Minimize costly repairs and maximize resource allocation by performing maintenance when it’s truly needed.

- Holistic View of Operations: Utilize integrated SCADA systems for a comprehensive overview of plant operations and proactive decision-making.

For those aiming to elevate their food processing capabilities, Innorobix offers cutting-edge solutions to seamlessly integrate predictive maintenance into your operations. Explore our tailored solutions or request a consultation/demo to witness firsthand how our technology can redefine your maintenance strategy. Reach out today and take the first step towards operational excellence and innovation in food processing.