Introduction: Creating Predictive Maintenance Alerts for Extrusion Equipment Using Tag Historian

In the realm of advanced manufacturing, the transition from reactive maintenance to predictive maintenance is pivotal in enhancing both efficiency and longevity of equipment. For extrusion processes, where precision is paramount, the integration of predictive maintenance strategies can lead to substantial improvements in operational reliability and cost savings. Utilizing Ignition’s Tag Historian, manufacturers can harness real-time data to anticipate equipment failures before they occur, thereby minimizing downtime and optimizing productivity.

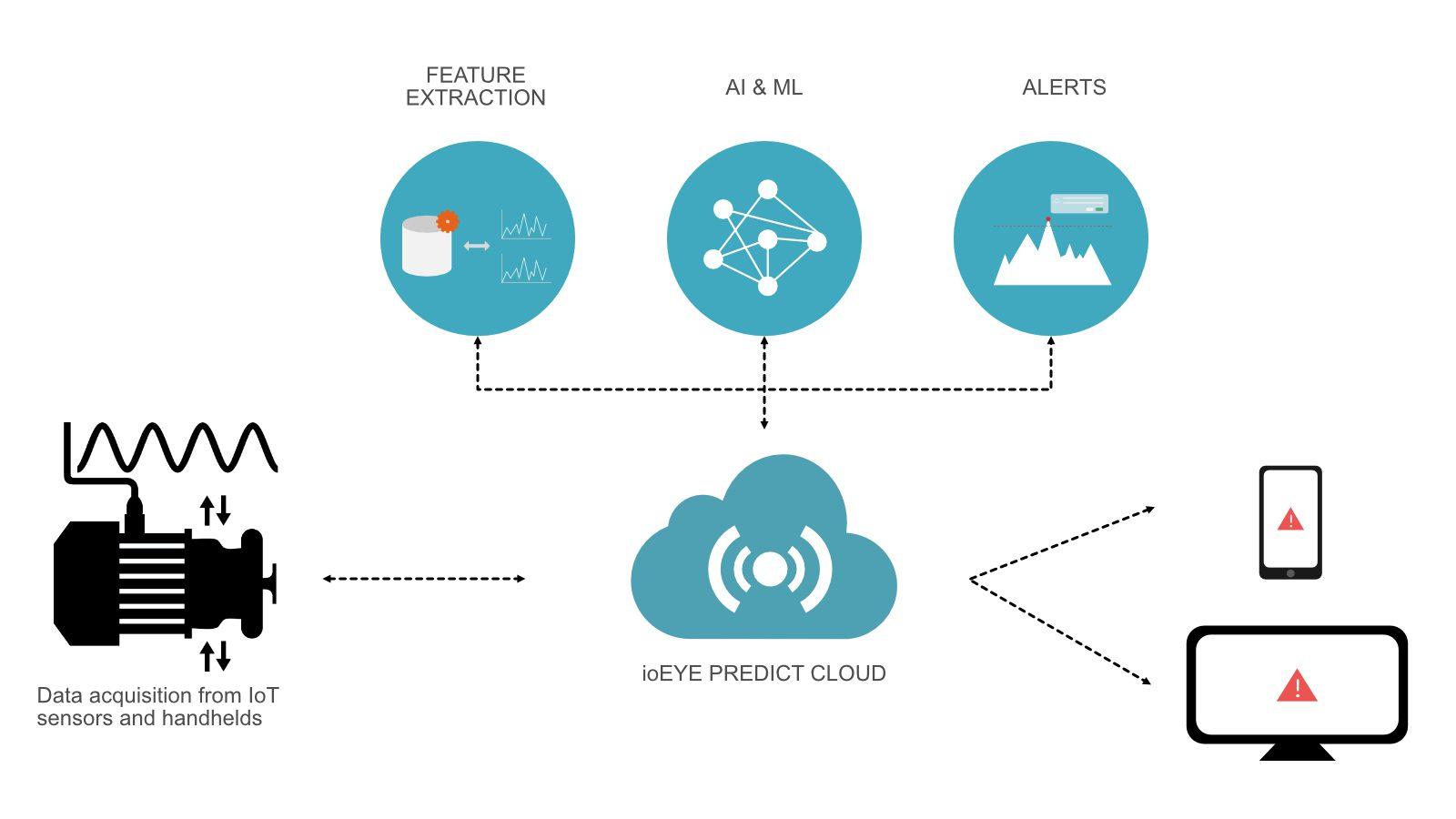

Tag Historian, a powerful tool within the Ignition platform, enables seamless data collection and analysis from various sensors and devices connected to extrusion equipment. By systematically capturing and interpreting ancient data, manufacturers can develop predictive maintenance alerts that are both timely and actionable. This article embarks on a detailed exploration of how to leverage tag Historian to establish these alerts, its benefits, and the practical steps involved.

Key Focus Areas:

- Data Collection Techniques: Understand the importance of capturing relevant parameters such as temperature, pressure, and motor load, and learn how to configure Ignition to log these crucial data points efficiently.

- Trend Analysis: Dive into techniques for historical data analysis, enabling the identification of patterns and anomalies that are precursors to equipment failure.

- Creating Alerts: Step-by-step guidance on setting up automated alerts based on threshold deviations, including integration with SCADA systems for real-time notifications.

- Case Study Examples: Real-world scenarios where predictive maintenance has preempted unscheduled downtimes and saved substantial costs, emphasizing the rationale behind choosing specific data points for monitoring.

- Sustainability Benefits: Highlighting the clean tech advantages of predictive maintenance, such as reduced energy consumption and material waste, contributing to a more sustainable manufacturing process.

This article will provide insights into the technological underpinnings of predictive maintenance and offer practical advice for deploying a robust alert system using Ignition’s Tag Historian. Through understanding these principles, businesses can propel their extrusion operations into a new era of efficiency and sustainability.

Understanding Tag Historian: Foundations for Predictive Maintenance in Extrusion

In our pursuit of integrating advanced predictive maintenance into our extrusion processes, the Tag Historian serves as a cornerstone tool that enables precise data collection and analysis over time. By storing time-series data,Tag Historian lets us track the conditions and performance of extruder components,such as barrel temperatures,screw torque,and motor current. This data can be crucial in developing predictive maintenance algorithms aimed at preventing unscheduled downtime.As an example, recording historical data on motor amperage can reveal trends leading to motor failure, prompting preemptive maintenance actions. Such an approach ensures machinery operates at optimal efficiency while minimizing energy consumption, aligning with our clean tech initiatives.

To effectively leverage the Tag Historian, we consider several practical steps. Firstly, establishing key parameters—like temperature, pressure, and vibration levels—would form the baseline of our monitoring regimen. By meticulously setting up these tags, correlated alerts can be generated for deviations from normal operating ranges, indicating potential issues. Moreover, machine learning models can utilize this historical data to forecast future failures with improved accuracy. For example, an increase in the frequency of vibration anomalies might predict bearing wear, triggering alerts well in advance. Employing insights from predictive analytics not only prolongs equipment life but also reduces environmental impact by optimizing resource use, a practical embodiment of clean technology principles in the manufacturing sector.

Configuring Tags and Historical Data Collection for Extrusion Equipment Monitoring

To configure tags for effective monitoring of extrusion equipment with Ignition’s Tag Historian, begin by identifying critical process variables such as temperature, pressure, speed, and torque. These are instrumental in predicting maintenance needs due to fluctuations indicating potential wear or failure conditions. By assigning tags to each of these variables within the Ignition platform, you can continuously track their real-time values. These tags serve as identifiers that link the physical parameters of your extrusion machine to the digital analytics provided by Ignition. As an example, create a tag for the barrel temperature today and map it to the relevant PLC data point. By structuring these tags hierarchically, such as parent tags for the machine level and child tags for specific sensors, you amplify the granularity and readability of data. This setup ensures seamless data collection and enhances the integrity of subsequent analysis.

Configuring historical data collection is pivotal in building a foundation for predictive maintenance alerts. Leveraging Ignition’s built-in Tag Historian module, enable long-term data storage on the process variables by setting appropriate sample rates and data retention policies. Such as, configure the Tag Historian to record data at one-minute intervals and retain this data for up to three years—perfectly balancing data granularity with storage efficiency. The historical data repository then becomes a treasure trove for analytics, empowering you to deploy tools like machine learning algorithms and trend analysis to spot anomalies and degradation over time. With concepts like moving average or exponential smoothing, establish thresholds for variables like motor vibration or die pressure. configuring this data correctly is instrumental in generating timely alerts, enabling preemptive actions before minor issues escalate into costly downtimes.

Analyzing Historical Data to Identify Maintenance Patterns and Predict Failures

In the realm of extrusion equipment maintenance, leveraging historical data is crucial for identifying patterns that precede equipment failures. Utilizing the Tag Historian feature in Ignition, operators can access a wealth of data logged over time to uncover these critical insights.By examining trends such as temperature fluctuations, motor load variations, or irregularities in pressure readings, maintenance teams can pinpoint anomalies that frequently enough herald mechanical issues. As an example, a sudden spike in motor current may indicate an impending motor bearing failure. Analyzing such data over a period allows for the identification of recurring issues linked to specific operational conditions, enabling teams to be proactive rather than reactive.

Advanced analytics can dive deep into the data, transforming raw numbers into actionable insights. Consider a scenario where vibration frequency data of a screw in an extrusion line is historically recorded using the Tag Historian. By applying machine learning algorithms, patterns emerge that correlate specific frequency changes with the onset of mechanical wear, empowering technicians to set up alerts before critical failures occur. To help operators visualize these patterns, employing Ignition’s powerful charting capabilities allows for the creation of intuitive dashboards. These dashboards highlight trends with color-coded alerts and dynamic displays, providing immediate visibility into the equipment’s health. Such proactive measures not only extend the lifespan of the machinery but also align with sustainability goals by minimizing resource wastage through unplanned downtimes.

Implementing Predictive Maintenance alerts: Best Practices and Considerations

When establishing predictive maintenance alerts for extrusion equipment through Tag historian, it’s essential to focus on data integrity and real-time analysis. Implement clean data management practices by ensuring that all tags related to critical machine components—such as motors, screws, and bearings—are accurately mapped and updated. Regular audits of tag configurations will help prevent inconsistencies that could trigger false alerts. for example, a data tag monitoring the vibration levels on an extrusion screw should adhere to predetermined thresholds. Consistent readings above this threshold can predict potential mechanical failure, allowing preemptive maintenance rather than unexpected downtime.

Consider the actionable intelligence that predictive maintenance alerts provide. It’s not simply about notifying operators of potential issues but equipping them with insights to take preventive steps effectively. Incorporate alert logic within your PLCs to integrate seamlessly with your existing SCADA systems and ensure the alerts are contextual and graded by severity. For instance:

- A minor alert might suggest increased wear detected by a change in thermal dynamics or vibration.

- An intermediate alert could indicate a clear deviation from standard operation parameters that require inspection within a 24-hour window.

- A critical alert might warn of imminent failure demanding immediate attention, such as a surge in energy consumption indicating severe friction or blockage.

Such stratified alerts not only prepare maintenance teams but also enhance resource allocation for sustainable operations, leading to reduced waste, extended equipment life, and minimized environmental impact.

In Retrospect

implementing predictive maintenance alerts for extrusion equipment using Tag Historian offers meaningful operational advantages. By leveraging historical data and trend analyses, manufacturers can preemptively address potential equipment failures, thus enhancing uptime and reducing maintenance costs. Key takeaways from this article include:

- Integration with Ignition’s Tag Historian: seamless data collection and storage allows for comprehensive analysis and robust predictive insights.

- advanced algorithm Deployment: Utilizing algorithms to identify performance deviations helps in predicting maintenance needs before actual failures occur.

- Efficient Resource Allocation: By predicting maintenance needs, companies can optimize labor and spare parts procurement, resulting in cost savings.

These enhancements not only build a more reliable production environment but also contribute to sustainable manufacturing practices by minimizing waste and energy consumption.To explore these solutions further, we invite you to partner with Innorobix for tailored automation strategies. Contact us today for a consultation or a demo to see how our expertise can definitely help propel your extrusion operations into the future of smart manufacturing.