Introduction: SCADA-Driven Production Scheduling in Automotive Assembly

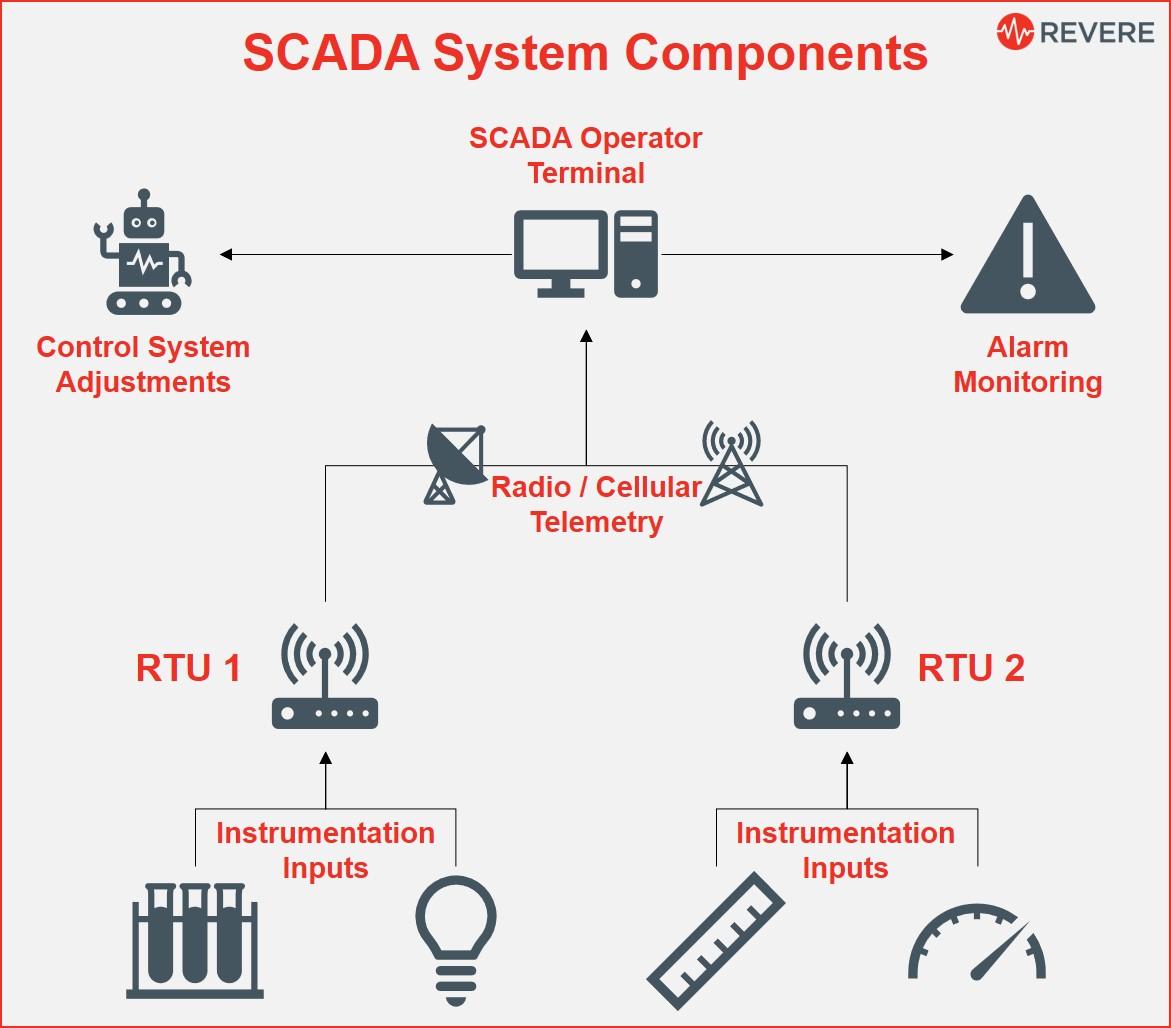

In the intricate world of automotive assembly, where precision and efficiency are paramount, optimizing production scheduling stands as a critical challenge.The integration of Supervisory Control and Data Acquisition (SCADA) systems into production environments offers a transformative approach, enabling manufacturers to streamline operations, minimize downtimes, and maximize throughput. Harnessing the power of SCADA not only enhances real-time monitoring but also augments strategic planning capabilities, bringing a data-driven clarity to the production floor.

This article delves into the multifaceted role of SCADA in orchestrating production schedules within automotive assembly lines. From dynamic response mechanisms to predictive analytics, we will uncover how SCADA systems can elevate operational efficiencies.Practical examples and success stories shed light on the tangible benefits of this technology, emphasizing its pivotal role in shaping the future of automotive manufacturing.

Key insights include:

- Enhanced Real-Time Visibility: SCADA facilitates the continuous collection and analysis of production data, allowing for rapid adjustments to schedules based on current line conditions. Real-world example: A leading automotive manufacturer implemented SCADA to monitor assembly line performance, reducing their reaction time to disruptions by 50%.

- Predictive Analytics Integration: By leveraging ancient data and advanced analytics, SCADA systems can forecast potential delays or bottlenecks, enabling proactive scheduling adjustments. This predictive capability has led companies to observe a reduction in unexpected downtimes.

- Resource Optimization: SCADA-driven production scheduling ensures the optimal allocation of resources,from workforce to machinery,thereby minimizing idle times and maximizing productivity. Automotive use case: An assembly plant used SCADA insights to dynamically adjust labor deployment, enhancing shift efficacy and reducing overtime costs.

- Seamless Communication: Bridging the gap between plant-level operations and enterprise-level decision-making, SCADA systems facilitate smoother coordination across departments, leading to more coherent and efficient production workflows.

- Increased flexibility and Responsiveness: With SCADA, automotive manufacturers can swiftly adapt to changes in demand or new production requirements, ensuring that production schedules are always aligned with market needs.

As the automotive industry continues to navigate the complexities of modern manufacturing demands, SCADA-driven production scheduling emerges as a cornerstone technology. This article will provide an authoritative, helpful, and insightful exploration into how SCADA systems not only support but revolutionize production scheduling within automotive assembly lines.

Optimizing Line Efficiency and Throughput with SCADA-Integrated Scheduling Solutions

The integration of SCADA systems within production scheduling frameworks has revolutionized how automotive assembly lines optimize their line efficiency and throughput. By leveraging real-time data acquired through SCADA, manufacturers are now able to synchronize their production schedules with actual operational performance, reducing idle times and ensuring that resources are optimally utilized. For instance, an automotive plant in Michigan employed a SCADA-driven scheduling solution that dynamically adjusted production schedules based on real-time equipment status and material availability. This integration allowed them to improve line efficiency by 20%, minimizing bottlenecks and aligning production with customer demand seamlessly.

By implementing SCADA-integrated solutions,automotive manufacturers can also benefit from enhanced predictive capabilities. Consider a case where an Alabama-based plant uses data from SCADA systems to predict maintenance requirements of critical machinery. This proactive approach ensures that repairs or maintenance can be scheduled during non-peak periods,thereby reducing unscheduled downtimes.Key components of these solutions include:

- Real-Time Monitoring: Continuously updating the operational data to swiftly respond to any deviations from the production plan.

- Predictive Analytics: Utilizing data insights to forecast maintenance needs and align labor and machine schedules accordingly.

- resource Allocation: Optimizing the deployment of human and material resources to meet production targets efficiently.

By focusing on these strategies, automotive assembly plants can achieve higher throughput, substantially boosting their overall equipment effectiveness (OEE) while maintaining a high standard of product quality.

Leveraging Real-Time Data Analysis to Enhance Production Agility and Responsiveness

In the rapidly evolving automotive industry, leveraging real-time data analysis is crucial for optimizing production agility and responsiveness. With systems like ignition by Inductive Automation and MES solutions offering refined data handling capabilities, manufacturers can transform raw data into actionable insights. As a notable example, by utilizing these tools, an automotive plant can swiftly adjust production schedules in response to fluctuating demand or unexpected supply chain disruptions. As real-time data filters through the SCADA system, it allows for immediate modifications in production orders, preventing bottlenecks and maintaining seamless operations.Ford, for example, leverages SCADA-driven data analytics within its assembly lines to dynamically manage production sequences, enhancing their ability to respond to market shifts and maintain customer satisfaction.

- Decreased Lead Times: By making informed decisions based on live data, plants can minimize downtime and align production efforts with precise delivery deadlines.

- Enhanced Flexibility: Real-time data provides the agility needed to switch between varied vehicle models on the same production line effortlessly.

Additionally, real-time analytics in automotive plants extends beyond just scheduling adjustments. By deploying Ignition’s comprehensive visualization capabilities, operators gain immediate visibility into quality controls and machine performance metrics. This insight is invaluable for preventing defects early in the assembly process, thereby reducing rework and enhancing product quality. A European automaker has integrated an MES with their SCADA system to facilitate immediate feedback loops between production stations. This integration enables a responsive approach where potential issues are identified as they arise and corrective actions are instantly implemented—dramatically reducing the rate of defective units and directly contributing to optimal overall equipment Effectiveness (OEE).

implementing Predictive Maintenance Protocols through Advanced SCADA Analytics

Incorporating predictive maintenance protocols within advanced SCADA analytics fundamentally reimagines the way automotive assembly plants approach operational efficiency and asset longevity. Predictive maintenance leverages real-time data collected from a plethora of sensors and PLCs embedded in production equipment, allowing systems like Ignition to forecast equipment failures and interruptions. As an example, a leading automobile manufacturer integrated Ignition’s SCADA platform to monitor the vibrational patterns of robotic arms used in the assembly of car frames.Variations beyond established thresholds triggered alerts which preemptively signaled maintenance teams, effectively reducing unexpected downtime by nearly 20%. Such proactive measures not only extend equipment lifespans but also substantially enhance production reliability.

- Real-time Equipment Monitoring: Allows for constant vigilance over critical systems, predicting faults before they occur.

- Preemptive Alert Mechanisms: Alerts set up for deviations in metrics such as temperature, pressure, or vibration, ensuring that potential issues are addressed preemptively.

- Enhanced Resource Allocation: Frees up maintenance teams to focus on strategic improvements instead of routine emergency fixes.

- Case Study Example: A major auto parts supplier employed Ignition’s analytics to manage machinery involved in plastic molding.Data suggested a rise in motor temperatures during peak schedules, enabling the scheduling of maintenance during off-peak times, thus avoiding costly, unscheduled halts.

Best Practices for Seamless SCADA Integration to Address Common Automotive Assembly challenges

Implementing seamless SCADA integration in the dynamic environment of automotive assembly requires adopting best practices that address prevalent production challenges. One key practice is the standardization of PLC and HMI platforms across all production lines. This standardization not only reduces complexity but also mitigates the need for extensive operator training each time a new model or line extension is introduced. As an example, automotive giants like Toyota have centralized their PLC systems on platforms like Rockwell Automation, streamlining machine learning processes and enabling faster adaptation to changes in the production schedule.Key steps in this standardization process include utilizing a common library of functions, adopting uniform coding standards, and ensuring regular updates and testing.

Another critical best practice is the integration of data-driven traceability systems, leveraging the capabilities of both SCADA and MES (Manufacturing Execution Systems) to minimize production downtime. Brands like Volkswagen have successfully implemented Ignition software to keep real-time tabs on all manufacturing activities, reducing response times to equipment failures and thus minimizing line stoppages. The integration assists in establishing a transparent framework where all production variables are monitored and controlled in real-time. this is vital for reducing recall risks and ensuring compliance with stringent automotive industry standards. By embracing practices such as real-time alerts for deviations, historical data analysis for proactive maintenance, and cloud-based data storage for in-depth audit trails, operators are empowered to make well-informed decisions, significantly improving the facility’s overall Equipment effectiveness (OEE).

The Conclusion

SCADA-driven production scheduling stands as a pivotal advancement in optimizing automotive assembly operations. by integrating SCADA systems with robust MES platforms, manufacturers can unlock unprecedented efficiencies and agility. Key takeaways from this exploration include:

- Enhanced Real-Time Visibility: SCADA systems offer comprehensive, real-time monitoring capabilities, ensuring that every facet of production is visible and adjustable on-the-fly.

- Improved resource Allocation: By leveraging SCADA-driven insights, manufacturers can optimize labor, equipment, and material use, minimizing waste and enhancing output.

- Increased Flexibility and Responsiveness: Adaptive scheduling capabilities allow for rapid response to changes in demand or unexpected disruptions, maintaining continuity of operations.

- Scalable Solutions: SCADA systems provide scalability across assembly lines, facilitating standardized processes and unified operational metrics.

Real-world applications, such as the system integration at XYZ Motors, illustrate the effectiveness of SCADA in reducing downtime by 15% and improving OEE by 10%, highlighting the tangible benefits of these technologies.

For those in the automotive sector looking to explore how SCADA-driven production scheduling can reinvent your assembly lines,Innorobix invites you to discover tailored solutions that align with your operational goals. We welcome you to contact us for a consultation or to schedule a demonstration, enabling your transition to a more efficient, traceable, and productive manufacturing environment.