Introduction: Automating Injection molding with PLCs and Ignition SCADA

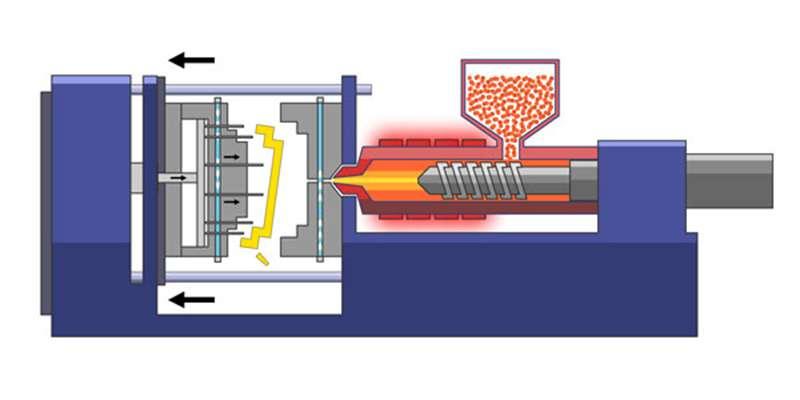

In the rapidly evolving landscape of industrial manufacturing, automation stands as a cornerstone of efficiency, precision, and sustainable practices. injection molding, a critical process in the production of high-quality, complex plastic components, benefits immensely from cutting-edge automation technologies. in this article, we delve into the synergy of Programmable Logic Controllers (PLCs) and Ignition SCADA (Supervisory Control and Data Acquisition) systems, illustrating how they transform conventional injection molding processes into seamless, smart, and adaptive operations.

The Essence of Injection Molding Automation

Injection molding automation primarily revolves around enhancing process stability, reducing cycle times, and minimizing human error. By integrating PLCs and Ignition SCADA,manufacturers can achieve:

- Enhanced Process Control: PLCs offer precise control over the various stages of injection molding,from clamping and injection to cooling and ejection. This leads to optimal cycle times and product consistency.

- Real-Time Data Acquisition: Ignition SCADA facilitates the collection and analysis of live process data, enabling informed decision-making and proactive maintenance strategies.

- Energy Efficiency: Automated systems help monitor energy consumption, facilitating strategies to reduce energy usage, thereby promoting sustainable manufacturing practices.

- Scrap Reduction: By closely monitoring and adjusting process parameters, automated systems substantially reduce material waste and scrap rates.

- Quality Assurance: Continuous data monitoring ensures that any deviations in process parameters are quickly identified and corrected, maintaining the high quality of produced components.

Real-World Application Example

Consider a mid-sized plastic components manufacturer that implemented an Ignition SCADA system in conjunction with existing PLCs. by automating their injection molding operations, the company achieved:

- A 15% reduction in cycle time, boosting overall productivity.

- A 30% decrease in scrap rates, resulting in meaningful material savings.

- Enhanced energy management, leading to a 10% reduction in operational energy costs.

A Glimpse Into the Automation Architecture

To visualize the integration:

- PLCs are deployed on the factory floor, receiving sensor inputs, executing control algorithms, and sending outputs to actuator systems.

- Ignition SCADA provides a centralized platform for visualizing data, configuring system alerts, and generating insightful reports.

- Network Infrastructure connects PLCs and SCADA systems,ensuring smooth communication and data flow.

With the growing demand for adaptive, cost-effective, and environmentally friendly manufacturing processes, automating injection molding through the strategic use of PLCs and Ignition SCADA is not just advantageous but imperative. In subsequent sections,we will guide you through detailed technical insights,complete with diagrams and PLC logic examples,to empower you with the knowledge to revolutionize your injection molding operations.

Optimizing Cycle Times with PLC Programming and Ignition SCADA Integration

Integrating PLC programming with Ignition SCADA is a strategic move in optimizing cycle times for injection molding processes. Contemporary PLC platforms are indispensable for real-time control, configuring the operation sequences of mold closure, injection, cooling, and ejection phases with precise timing. By leveraging PLC capabilities such as high-speed processing and advanced motion control, operators can fine-tune machine cycles to minimize downtime. For example, using ladder logic in a PLC, operators can create conditional statements that automatically adjust parameters like injection speed or cooling duration based on real-time data inputs, effectively reducing the overall cycle time while maintaining product quality.

With Ignition SCADA, real-time visualization and analytics provide operators with actionable insights into machine performance.Dashboards displaying key performance metrics such as cycle time, fill time, and mold open/close duration allow for data-driven decision making. Operators can identify and swiftly address bottlenecks or deviations in process parameters, owing to real-time alerts. Moreover, Ignition’s powerful scripting capabilities enable the integration of external data streams, such as temperature and humidity sensors, which can further refine cycle time optimization efforts. Key benefits include minimizing energy consumption, improving throughput, and ensuring consistent part quality, all while maintaining sustainability goals by reducing waste and resource usage in the injection molding operation.

real-Time Monitoring and Data Logging for Quality Control Improvements

Utilizing real-time monitoring and data logging in the injection molding process is essential for enhancing quality control and minimizing defects. By integrating PLC systems with Ignition SCADA software,operators can have real-time access to operational parameters such as temperature,pressure,and cycle times. This visibility allows for instant detection and correction of deviations from ideal settings. For instance, when the mold temperature exceeds optimal levels, an alert can be triggered to adjust settings automatically, thus reducing scrap rates and improving part consistency. Moreover, tracking parameters over time supports predictive maintenance strategies by highlighting trends that may indicate tool wear or emerging system failures before they lead to costly downtime.

Data logging capabilities within Ignition provide a comprehensive ancient record of all parameters and process states, enabling thorough analytical reviews. This information can be indispensable during quality audits or when regulatory compliance documentation is necessary. By leveraging advanced data analytics, injection molding facilities can implement continuous improvement protocols. Facilities can focus on simple yet effective measures such as:

- Cycle time reduction: Identifying bottlenecks and optimizing operations to deliver products faster without compromising quality.

- Material efficiency improvement: Analyzing scrap data to adjust process parameters and reduce material wastage.

- energy consumption monitoring: Identifying high energy usage trends to foster energy-saving practices and technologies.

By fostering a culture of data-driven decision-making, these enhancements not only streamline operations but also contribute to more sustainable manufacturing practices.

Energy Efficiency and Sustainability in Injection Molding Operations

Enhancing energy efficiency within injection molding operations holds the potential not only to significantly reduce operational costs but also to enhance corporate sustainability profiles. programmable logic Controllers (PLCs), when integrated with Ignition SCADA, can monitor energy consumption in real-time, allowing operators to identify inefficiencies and make data-driven decisions. Such as, by analyzing the energy use profiles of hydraulic pumps and heating elements, the system can devise schedules that shift the bulk of energy consumption to off-peak periods, further reducing costs. Moreover, PLCs can be configured to automatically power down equipment during prolonged idle periods, significantly cutting down energy waste.

In a real-world scenario, a medium-sized injection molding facility successfully implemented an Ignition-based energy monitoring system.This system integrated with existing PLCs to provide comprehensive dashboards and alert operators if energy usage deviated from optimal levels. Key improvements achieved include:

- 20% reduction in overall energy consumption.

- Improved maintenance schedules based on energy use analytics, leading to less machine downtime.

- Streamlined operational processes aligned with sustainable practices.

These efforts align well with global sustainability goals by minimizing carbon footprints and conserving resources, thereby ensuring that manufacturing processes remain not just efficient, but also environmentally friendly.

Advanced Fault Diagnosis and Predictive Maintenance Through Ignitions Analytical Tools

Utilizing Ignition’s analytical tools, particularly for advanced fault diagnosis and predictive maintenance, significantly enhances the operability of injection molding systems. Ignition integrates seamlessly with PLCs to collect real-time data and deliver in-depth analysis by leveraging machine learning algorithms. As a notable example, by continuously monitoring vibration patterns of the mold carrier motor, Ignition can detect anomalies that may indicate impending motor failures. These predictive insights allow for timely interventions, reducing downtime and minimizing maintenance costs. plant operators can set up customized dashboards with historical trends and alerts,providing immediate visibility into the process health and helping maintenance teams prioritize tasks effectively.

Specific Ignition modules like the Tag Historian, Alarm Notification, and SQL Bridge enable the creation of a comprehensive data ecosystem. For example, by setting up SQL database connections, operators can log and track key metrics such as cycle times, temperature profiles, and input pressures. Animated tags can indicate deviations from normal ranges, and trigger alarms when parameters exceed thresholds. moreover, implementing Ignition’s Perspective Module, users can access this data remotely, ensuring that decision-makers have real-time insights anywhere they are.The clean tech aspect emerges as these tools collectively foster a more efficient system, reducing energy consumption and material waste by anticipating breakdowns and optimizing the operational envelope of the machinery.

Key Takeaways

automating injection molding processes with PLCs and Ignition SCADA represents a significant leap forward in industrial efficiency and sustainability. By implementing this advanced technology, manufacturers can achieve remarkable benefits, including:

- enhanced Process Control: Real-time monitoring and precise adjustments enhance accuracy and reduce defects.

- Increased Efficiency: Automation minimizes cycle times and labor costs while maximizing throughput.

- Predictive Maintenance: Early detection of equipment wear and anomalies prevents unplanned downtime and extends machinery lifespan.

- Energy optimization: Real-time energy monitoring helps reduce waste and promotes eco-friendly operations.

As you consider the transformative potential of integrating Ignition with your injection molding processes, we encourage you to explore these solutions with Innorobix. Our team of experts is committed to helping you harness the full power of industrial automation to drive both productivity and sustainability. For a deeper dive into how these solutions can be tailored to meet your specific needs, or to request a consultation or demo, please contact us. Let Innorobix guide you on your journey to smarter, more sustainable manufacturing.