Introduction: Detecting Anomalous Power Draw as a Maintenance Signal

In the realm of modern manufacturing, predictive maintenance has emerged as a cornerstone strategy for optimized operations and minimizing unexpected equipment failures. A critical component of this strategy is the ability to detect anomalous power draw patterns from machinery, which often serve as early indicators of potential mechanical issues. By leveraging advancements in data acquisition and analysis, manufacturers can not only preempt costly downtimes but also fine-tune resource allocation for enhanced shop floor efficiency.Anomalous power draw refers to irregularities in the energy consumption profile of a machine, which deviate from its normal operational baseline. Such deviations can signify:

- Impending mechanical failures like motor or bearing wear.

- Inefficient tool engagement or defective process conditions.

- Electrical issues such as short circuits or insulation breakdowns.

In practice, detecting these anomalies involves:

- Implementing Sensors and IoT Devices: Install power meters and IoT-connected sensors on CNC machines to continuously monitor power usage.

- Data Integration with Advanced Systems: Use systems like Ignition and MTConnect for seamless data capture and visualization. These systems facilitate real-time monitoring and historical analysis.

- Machine Learning Algorithms: Employ predictive analytical models to identify patterns and deviations that human operators might miss.

- Automated Alerts and Maintenance Scheduling: Integrate alerts directly into MES systems to automate maintenance scheduling and operational responses,minimizing human intervention.

Example Scenario:

consider a CNC machine in an aerospace component manufacturing plant. Historically, this machine operates with a consistent power draw during its standard milling operations. However, over a series of shifts, a gradual increase in power consumption is observed without corresponding increases in output. By analyzing this anomaly using MTConnect data streamed into an MES system, operators can identify issues such as cutting tool wear or spindle misalignment before they escalate into more serious failures.

This proactive approach not only safeguards the integrity of expensive equipment but also significantly enhances ROI by reducing unscheduled downtimes. Employing technologies like the Innorobix MTConnect module, manufacturers can efficiently extract and utilize machine data, paving the way for more informed and strategic maintenance decision-making.

In this article, we will delve deeper into methodologies for capturing and analyzing power draw anomalies, exploring case studies, and providing actionable insights into deploying these techniques for robust shop floor optimization.

Detecting Power Draw Anomalies through Advanced Sensor Integration Strategies

the integration of advanced sensor technology with MTConnect protocols opens a gateway for real-time monitoring and analysis of power draw anomalies in CNC machines. Sensors strategically mounted on machines can deliver granular data about energy consumption patterns, allowing for a deeper dive into operational efficiency. By leveraging the Innorobix MTConnect module, this data can be continuously streamed into a centralized Ignition SCADA dashboard, where elegant algorithms analyze and identify any deviations from standard power usage profiles. Consider, such as, a CNC spindle that exhibits a spike in power consumption during a simple drilling operation. Such an anomaly could indicate tool wear or misalignment, prompting immediate maintenance interventions to prevent catastrophic machine failures.

This approach not only enhances predictive maintenance capabilities but also plays a pivotal role in automating shop floor optimization by streamlining OEE (Overall Equipment Efficiency) improvements. with MTConnect’s standardized data models, the downtime scenarios traditionally dictated by after-the-fact manual logs can be preempted with instantaneous alerts. In real-world applications:

- Reduction in Downtime: Anomalies detected early can lead to preemptive troubleshooting, reducing downtime by up to 30%.

- Cost Savings: By avoiding unscheduled maintenance, shops can witness notable cost savings—often running into thousands of dollars annually.

- Enhanced Machine Lifecycle: Consistent monitoring and timely interventions can extend the lifecycle of machinery by an estimated 20%.

With these advantages, companies are empowered to transition from reactive to proactive maintenance strategies, ultimately enhancing their return on investment (ROI).

Implementing Predictive Maintenance via Data Analytics with MTConnect

Harnessing predictive maintenance within your manufacturing environment involves leveraging real-time data analytics to anticipate equipment failures before they occur. Using MTConnect as a standardized dialog protocol, you can accurately monitor spindle load as a key indicator of machine health. Deviations from normal power draw can be early warnings of tool wear, misalignment, or other mechanical issues. By integrating MTConnect with platforms like Ignition, you get a robust data pipeline from your CNC machinery straight into your analysis and maintenance workflow. Imagine a scenario where a CNC milling machine typically operates at a power draw of 7 kW.A sudden spike to 11 kW during a routine aluminum milling cycle could be indicative of a forthcoming spindle-bearing failure. Automation through Ignition alerts your maintenance crew to inspect and address the issue immediately, reducing the risk of unscheduled machine downtime. This proactive maintenance approach not only mitigates risks but also prolongs equipment lifespan, thereby optimizing the shop’s return on investment (ROI).

For a more effective implementation, encourage integration with an MES (Manufacturing Execution System). MES can log spindle load data against production schedules, providing a detailed historical record that is invaluable for pattern recognition and anomaly detection. This process allows for automatic logging of anomalies, empowering your team to address issues without relying on manual tracking or human memory. With the Innorobix MTConnect module, detailed analytics can be extracted to help shop floor managers understand trends over extended periods. Here are some specific benefits:

- Reduced downtime due to early detection of potential failures.

- Enhanced production quality through consistent monitoring and adjustment.

- Cost-efficiency through the optimized maintenance schedules.

Ultimately, through mtconnect, your shop can achieve a predictive maintenance paradigm that not only prevents catastrophic machine failures but also paves the way for seamless, automated, and clever shop floor operations.

leveraging Spindle Load Monitoring for Enhanced Asset Performance

Detecting anomalies in spindle load can transform maintenance routines from reactive to proactive, significantly enhancing asset performance. Utilizing the Innorobix MTConnect module integrated with Ignition and MES systems, manufacturers can access real-time spindle load data, aiding in the precise identification of unusual power draws. For example, a sustained spike in spindle power consumption might indicate tooling issues, such as worn or fractured tools, which can lead to suboptimal machining conditions. By diagnosing and correcting these anomalies promptly, manufacturers can prevent costly downtime and extend machine and tool life.

Best practices for leveraging spindle load data include:

- Configuring alert thresholds for power consumption beyond normal operating parameters,allowing for immediate interventions.

- Automating downtime logging through Ignition’s event-triggered actions,thereby reducing manual recording errors and enhancing efficiency.

- Correlation analysis between spindle load data and associated parameters like feed rate and speed to uncover deeper insights into machine performance. Take, for instance, a CNC router whose spindle load increases during specific programming cycles; this could unveil opportunities for optimizing cutting strategies. Implementing such practices can lead to improved productivity, reduced overall operational costs, and an elevated ROI by enabling data-driven decision-making.

Maximizing Machine Uptime with Automated Anomaly Detection Systems

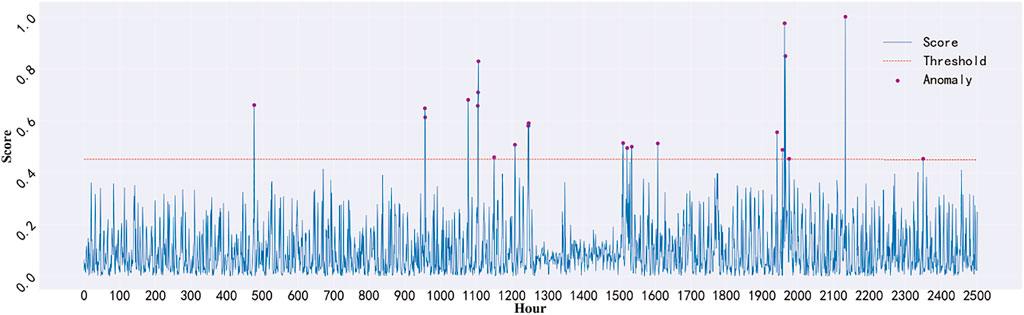

Leveraging the capabilities of MTConnect, our Innorobix module captures data such as spindle load—critical for identifying potential issues before they escalate into major maintenance headaches. Imagine a scenario where a CNC machine’s spindle has historically shown patterns of gradual increases in power consumption before a breakdown. By utilizing data parsed through MTConnect, discrepancies in power draw are flagged in real-time. This isn’t speculation; it’s a procedure rooted in evidence. as a notable example,a typical spindle may require an average load of 50% during normal operation. If our system detects a deviation reaching 65% load under the same conditions, it triggers an alert to the maintenance team, frequently enough days before an actual failure, giving factories preemptive scheduling capabilities for maintenance.

Implementing an automated anomaly detection system provides a robust feedback loop, relieving operators from the burden of constant manual monitoring. Benefits include:

- Reduced unplanned Downtime: Quick identification of deviations that signal impending failures prevents surprise machine outages.

- Enhanced Predictive Maintenance: Recognize patterns over time and schedule interventions at optimal times, reducing disruptions to production schedules.

- Data-Driven Insights: By continuously analyzing trends in spindle power draw, shops gain valuable insights for machine performance optimization.

This constant vigilance translates directly into ROI, transforming maintenance from a reactive to a proactive strategy—and that’s the key to maximizing machine uptime.

Concluding Remarks

detecting anomalous power draw on the shop floor serves as a pivotal maintenance signal that can significantly enhance operational efficiencies, mitigate unexpected breakdowns, and optimize machine performance. By leveraging the Innorobix MTConnect module, manufacturers can seamlessly capture and analyze spindle load data, integrating these insights into advanced MES systems and laying the groundwork for predictive maintenance protocols. Key takeaways include:

- real-time Monitoring: Continuously track spindle load variations to identify deviations and anomalies promptly.

- proactive Maintenance: Utilize anomaly detection as a cue for maintenance, preventing costly unplanned downtime.

- Data-Driven Insights: Capitalize on MTConnect’s standardized data extraction capabilities for actionable insights.

- Cost Efficiency: Streamline operations and reduce maintenance costs through early anomaly identification.

- enhanced ROI: Drive an increase in equipment longevity and productivity, yielding a better return on investment.

We invite you to explore how the Innorobix MTConnect module can transform your manufacturing processes. Contact us today for a tailored consultation or to experience a live exhibition, showcasing how real-time insights can lead to considerable improvements in shop floor management and resource optimization.