Introduction: Leveraging Ignition SCADA for Lean Manufacturing Excellence

In today’s fast-paced automotive manufacturing landscape, the pursuit of lean principles is more critical than ever. Lean manufacturing is centered around minimizing waste while maximizing productivity and efficiency. To achieve these goals, manufacturers are increasingly turning to advanced technologies like Ignition SCADA (Supervisory Control and Data Acquisition) systems. Ignition offers a versatile and scalable solution that not only enhances operational performance but also aligns seamlessly wiht lean initiatives.

By integrating Ignition SCADA into automotive manufacturing processes, companies can unlock numerous benefits:

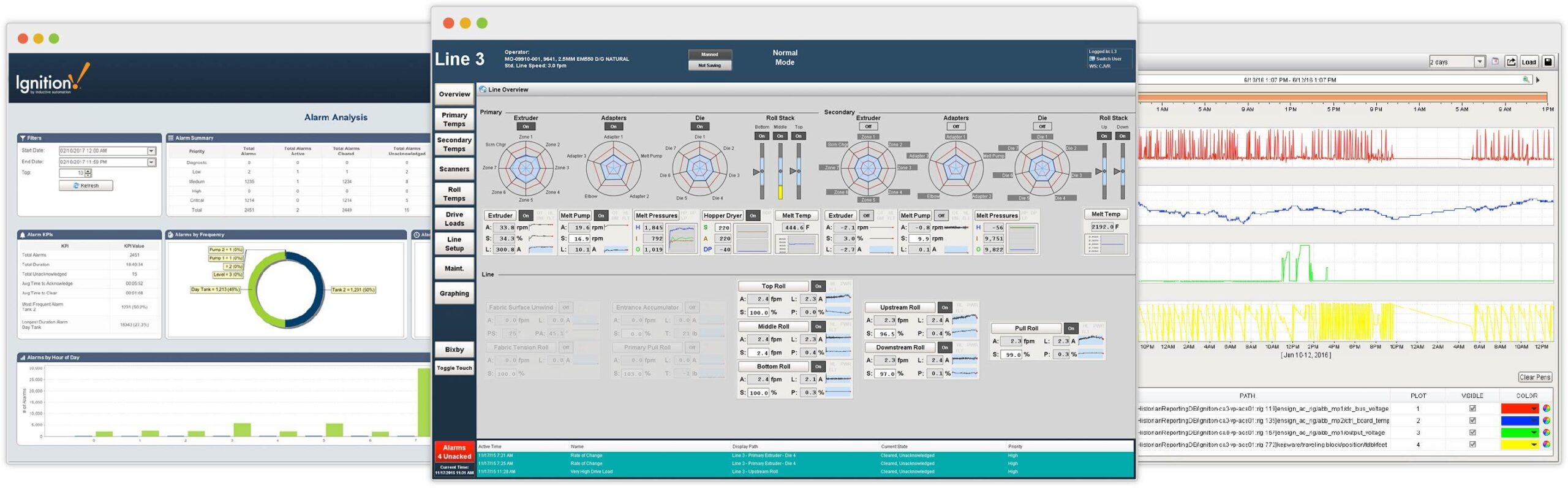

- Real-Time Data Monitoring: With Ignition, manufacturers can gain unprecedented visibility into production processes, allowing them to monitor key performance indicators (kpis) in real time. This immediate insight facilitates quicker decision-making,reducing cycle times and improving responsiveness.

- Enhanced Traceability: Utilizing SCADA to digitize traceability processes enables a more streamlined approach to tracking parts and components throughout the manufacturing line. This reduces the risk of errors and facilitates rapid root-cause analysis in case of quality issues, supporting continuous enhancement efforts.

- Standardized PLC/HMI Interfaces: By standardizing Programmable Logic Controller (PLC) and Human-Machine Interface (HMI) systems across production lines, automotive manufacturers can achieve consistency in operations. This standardization reduces training times, minimizes errors, and supports smoother inter-line transitions, enhancing overall equipment effectiveness (OEE).

- Reduced Downtime: Ignition’s ability to integrate seamlessly with manufacturing execution systems (MES) enables predictive maintenance strategies, significantly cutting down on unplanned downtime by preemptively identifying equipment issues before they escalate.

- Improved Overall Equipment Effectiveness (OEE): With a extensive view provided by Ignition,manufacturers can easily identify bottlenecks and inefficiencies,making it possible to refine processes and optimize resource utilization continually.

In this article, we will delve deeper into real-world applications of Ignition SCADA within the automotive sector, illustrating how this solution is helping firms to achieve and exceed their lean manufacturing objectives. Through practical examples and case studies, readers will gain an authoritative understanding of the transformative impact Ignition can have on their operations.

Implementing Real-Time Data Acquisition for enhanced Process Efficiency

Enhancing process efficiency with real-time data acquisition is a core component of supporting lean manufacturing initiatives in the automotive sector. by deploying Ignition SCADA, manufacturers can seamlessly integrate with existing plant floor equipment to gather data 24/7, providing a robust foundation for real-time monitoring and control. This access to real-time data allows for immediate identification and resolution of bottlenecks in the production line. For instance, a major automotive client successfully noticed a important reduction in assembly line stoppages by using Ignition SCADA to monitor equipment status through a series of IoT-enabled sensors directly interfaced with their PLCs. This real-time insight not only improved machine utilization but also aided in effective decision-making, thereby expediting corrective actions and supporting lean practices.

In addition to leveraging real-time data,automakers can employ Ignition SCADA to enhance process efficiency through data-driven predictive maintenance. by continuously collecting and analyzing machine health metrics, maintenance teams can predict potential equipment failures before they result in unexpected downtime. For example, a renowned vehicle manufacturer integrated Ignition SCADA with their Manufacturing Execution Systems (MES) to track and analyze vibration trends in critical machinery.As an inevitable result, they achieved a 20% reduction in unscheduled downtime and extended the lifespan of their machines by 15%. These improvements demonstrate how manufacturers can harness real-time data to transition from reactive to proactive maintenance strategies, embodying the principles of lean manufacturing.

Leveraging MES Systems to Streamline Production Workflow

Manufacturing Execution Systems (MES) have become an integral component in enhancing production efficiency, notably within the high-paced automotive sector. By integrating Ignition SCADA with MES, automotive manufacturers can streamline production workflows through increased connectivity and visibility into operations. As a notable example, a major automotive manufacturer faced challenges with siloed data across its production lines, resulting in delayed decisions and longer ramp-up times. By implementing Ignition’s robust data integration capabilities,the manufacturer was able to achieve real-time monitoring and data aggregation,thus providing a unified view of the entire production process. This led to immediate access to critical insights that significantly reduced response times and minimized production downtimes,aligning perfectly with lean manufacturing goals.

Moreover, MES systems empower manufacturers to implement standardized procedures that maintain production consistency and quality across all lines. For example,common issues such as variations in component assembly times and unpredicted machine maintenance were meticulously documented and analyzed. Using Ignition’s scripting capabilities, the plant was able to deploy custom alerts and workflows tailored to minimize these deviations, effectively enhancing the Overall Equipment Effectiveness (OEE). Additionally, critical traceability was digitized, allowing the automotive plant to quickly pinpoint quality issues and track them back to their root cause efficiently. By employing such standardized and automated workflows, automotive manufacturers not only support lean initiatives but foster a culture of continuous improvement and operational excellence.

Standardizing PLC/HMI Interfaces for Consistent Operations

Achieving consistent operations across an automotive manufacturing facility requires standardizing PLC/HMI interfaces,ensuring that every line operates seamlessly irrespective of the variations in machinery or system age. Leveraging Ignition SCADA by Inductive Automation, coupled with lean manufacturing principles, provides a robust framework to standardize these interfaces effectively. Ignition uses a modular architecture allowing for unified PLC/HMI interfaces that can be easily scaled and customized without significant downtime. By centralizing data collection and control into a single platform, manufacturers can achieve uniform interfaces that substantially reduce the complexity of operator training and streamline maintenance procedures. For example, an automotive plant in Detroit utilized Ignition to consolidate disparate PLC systems across their welding and assembly lines, leading to a more synchronized production schedule and reducing unexpected system failures by 20%.

The standardization process also introduces powerful interoperability features, ensuring that diverse machines speak the same “language” across your production lines. Implementing a standardized set of PLC tags ensures reliability and simplifies troubleshooting, as operators and maintenance engineers can reference a common framework. Additionally, using Ignition’s OPC UA capabilities facilitates seamless data interaction regardless of equipment manufacturer. Consider a facility with varying models of CNC machines; by standardizing HMIs through Ignition’s Vision Module, each CNC machine’s HMI delivers a uniform user experiance, minimizing operator errors and enhancing overall equipment effectiveness (OEE). The result is not just consistent operations but also an actionable insight platform that drives informed decision-making, contributing to leaner, more efficient manufacturing processes.

boosting Overall Equipment Effectiveness with Advanced SCADA Solutions

Advanced SCADA solutions like Ignition can dramatically enhance Overall Equipment Effectiveness (OEE) by integrating comprehensive data visualization and real-time analytics into the manufacturing process. In the automotive industry, where precision and efficiency are paramount, Ignition enables seamless machine-to-machine communication, fostering a more responsive and agile production environment. Consider a scenario where an automotive plant has traditionally suffered from bottlenecks due to unanticipated machine failures.By implementing Ignition SCADA, the plant can proactively monitor equipment health and performance, thereby identifying potential issues before they lead to downtime. This proactive maintenance approach ensures constant equipment availability, significantly boosting OEE.

Furthermore, Ignition supports lean manufacturing initiatives by streamlining data collection and analysis, wich is critical for identifying waste and optimizing processes. As an example, in a facility responsible for producing automotive chassis, Ignition’s integration with MES systems allows operators to access past data and current production metrics through a unified interface. This capability simplifies the identification of inefficiencies. Using Ignition’s powerful analysis tools, stakeholders can visualize production trends and implement improvements by leveraging features such as:

- Customizable dashboards – Allow real-time visibility into production metrics, highlighting areas ripe for improvement.

- Alarm notification and management – Quickly alerts operators to deviations from normal conditions, minimizing potential disruptions.

- Recipe management – Ensures consistency in production processes by automating setup and reducing chances for human error.

These functionalities empower automotive manufacturers to respond swiftly to production anomalies, thereby maintaining high levels of machine efficiency and advancing their lean manufacturing goals.

Insights and Conclusions

implementing Ignition SCADA within automotive manufacturing processes offers profound enhancements to lean manufacturing initiatives. By utilizing its robust capabilities, manufacturers can significantly reduce downtime, enhance traceability, unify PLC/HMI standards, and improve OEE. Key takeaways include:

- Enhanced connectivity: Ignition’s open architecture facilitates seamless integration with existing systems, promoting real-time data visibility across the production line.

- Improved Traceability: Digitized traceability empowers manufacturers to quickly track and respond to production anomalies, thus reducing waste and enhancing quality control.

- Standardized Automation: A unified approach to PLC/HMI deployment ensures consistent production processes and simplifies troubleshooting efforts, thereby minimizing disruptions.

- Optimized OEE: Through detailed analytics and reporting, Ignition drives continuous improvement in machine efficiency and productivity.

We invite you to explore these transformative solutions with Innorobix, helping you unlock new levels of operational excellence. For a personalized consultation or to request a demo, please contact us today to see how Ignition can drive your lean manufacturing goals to the next level.