Introduction: OEE Calculation and Visualization with Ignition for Stamping Plants

In the competitive landscape of the automotive industry, the optimization of manufacturing performance is a primary focus for stamping plants. Key performance indicators, notably Overall Equipment Effectiveness (OEE), serve as critical metrics in assessing the efficiency of production lines. OEE not only quantifies the percentage of planned production time that is truly productive but also highlights areas for improvement across various stages of the manufacturing process.

OEE Calculation and Visualization with Ignition offers a robust framework that enables stamping plants to enhance productivity, reduce waste, and drive operational excellence. The Ignition platform, a premier industrial request progress software, allows real-time data collection, analysis, and visualization, making it easier for manufacturers to make informed decisions.

Key Benefits of OEE Calculation and Visualization

- immediate Insights: Real-time dashboards provide operators and management with immediate insights into performance metrics, allowing for swift, data-driven decisions.

- Enhanced Traceability: Digitizing data capture and traceability ensures that every aspect of production is documented and easily accessible, facilitating continuous improvement.

- Standardization of Processes: using a unified platform, such as Ignition, across multiple lines and machines promotes consistency in method and reduces configuration errors associated with various legacy systems.

- Identification of Bottlenecks: Advanced visualization tools make it straightforward to pinpoint where delays are occurring, allowing for targeted interventions.

Real-World Applications in Stamping Plants

- Case Study: Automaker A

- automaker A implemented Ignition to visualize OEE metrics across a series of stamping lines.

– Resulted in a 20% improvement in production efficiency by quickly identifying and resolving downtime causes.

- Case Study: Tier-One Supplier B

- Supplier B utilized Ignition’s data analytics to trace material flow.

– Enhanced visibility allowed them to reduce scrap rates by 15% by improving quality control measures throughout the stamping process.

- Case Study: Manufacturer C

– Manufacturer C standardized PLC and HMI interfaces with Ignition, facilitating maintenance and training.

– Led to a smoother launch of new production lines, reducing the typical ramp-up time by 30%.

As the automotive sector demands heightened precision and efficiency, leveraging advanced platforms like Ignition for OEE calculation and visualization equips stamping plants with the necessary tools to meet both current and future challenges. This article delves deeper into the direct implementations, tools, and methodologies that can empower stamping facilities to achieve excellence in operational performance.

Understanding OEE and Its Importance in Stamping Plants

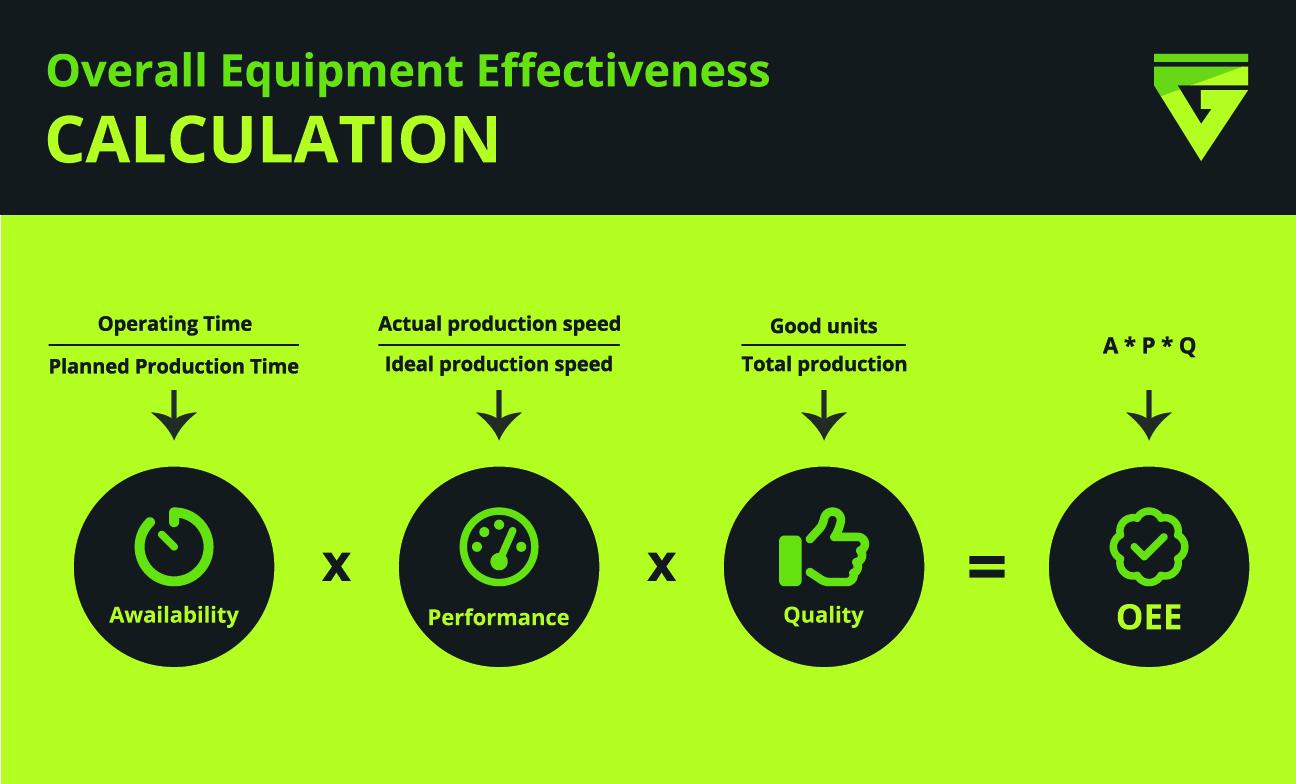

Overall Equipment efficiency (OEE) is a critical metric for assessing the effectiveness of production processes in stamping plants. It combines three vital components: availability, performance, and quality. Availability accounts for any downtime in production, including maintenance and equipment failures. For instance, if a stamping press experiences frequent breakdowns due to outdated PLC systems lacking real-time monitoring, this impacts overall productivity significantly. By integrating Ignition’s MES capabilities, manufacturers can establish real-time alerts and remote diagnostics, thus minimizing downtime. Moreover, when we analyze OEE data across multiple lines, it becomes evident wich machines require immediate attention, allowing for proactive maintenance schedules that enhance operational continuity.

Performance, on the other hand, measures the speed at which a machine operates compared to its maximum potential. For example, if a stamping line is designed to produce 1000 parts per hour but only delivers 800 due to inefficiencies, the performance rate would drop. Ignition can visualize this data, enabling operators to identify bottlenecks and streamline thier processes effectively, ensuring that every component of the production line meets optimal performance levels.Lastly, quality focuses on the defects per production run. Implementing real-time quality monitoring solutions within MES systems allows for the immediate identification of quality issues, leading to a rapid response to defects. All of these factors work synergistically, illustrating not only the importance of OEE but also demonstrating how Ignition can empower stamping plants to enhance operational efficiency significantly.

Key Components of OEE Calculation: Availability, Performance, and Quality

To achieve effective OEE (Overall Equipment Effectiveness) calculation in stamping plants, it is crucial to focus on three key components: Availability, Performance, and Quality. Availability refers to the actual operational time of the stamping machine versus the planned production time. For instance, if a machine is scheduled to run for 10 hours but experiences 2 hours of unplanned downtime due to a mechanical failure, its availability would be 80%. Monitoring equipment and utilizing real-time alerts through systems like Ignition can drastically reduce unexpected downtimes, enhancing availability metrics. Sensors in your stamping presses can help detect issues proactively, allowing for timely maintenance interventions before failures occur.

Next, Performance is concerned with the speed at which the machines produce compared to their designed capacity. In a stamping plant, if a press is rated to produce 100 pieces per hour but only outputs 85, your performance calculation will reflect an efficiency of 85%. The key to improving performance lies in standardized training for operators and effective integration of MES (Manufacturing Execution Systems) with Ignition to fine-tune processes. Implementing dashboards that visualize real-time performance metrics can help identify bottlenecks or areas for improvement quickly. Lastly, Quality measures the number of good parts manufactured compared to the total produced. For example, if out of 100 parts, only 95 meet the quality standards, your quality rate is 95%. Systems like Ignition can track defects in real-time, allowing instant identification and resolution of quality-related issues, which is paramount in high-stakes environments such as the automotive sector.

Leveraging Ignition for Real-Time OEE Visualization and Data Insights

In the automotive stamping industry, real-time data visibility is crucial for monitoring and enhancing Overall Equipment Effectiveness (OEE).Utilizing Ignition, manufacturers can seamlessly integrate data from various sources, including PLCs, HMIs, and MES systems, to create a centralized dashboard that provides instant access to key metrics. This enables operators and management alike to identify issues promptly and take corrective actions before they escalate. For instance, a stamping plant can set up dashboards to display metrics such as availability, performance, and quality, allowing them to identify specific machines or lines that are underperforming during real-time production runs.

moreover, Ignition’s capabilities can be harnessed to create a customizable alert system, notifying operators about potential downtimes or production inefficiencies as they occur. such as, if a press is operating below its expected cycle speed, the system can trigger alerts, prompting immediate examination. The integration of past data allows for the analysis of past performance trends, empowering managers to make data-driven decisions regarding maintenance schedules and operational improvements. By implementing such a system, one automotive manufacturer was able to reduce unplanned downtime by 20%, significantly increasing both productivity and profitability while ensuring a higher standard of quality throughout the production process.

Implementing Continuous Improvement Strategies to Optimize OEE in Stamping Processes

Implementing continuous improvement strategies within stamping processes is crucial for optimizing Overall Equipment Effectiveness (OEE). This can be achieved by employing real-time data analytics and automation tools like Ignition. For example, a leading automotive manufacturer successfully enhanced their stamping process by integrating Ignition’s real-time monitoring capabilities. They captured key performance indicators (KPIs) such as cycle time, machine availability, and quality rates directly from their machines. By visualizing this data on customizable dashboards, operators were empowered to identify bottlenecks and areas of inefficiency promptly. This structured approach allowed them to conduct focused problem-solving sessions that resulted in reduced cycle times by 15% and significantly decreased machine downtime.

In addition to data visualization, the standardization of processes across multiple stamping lines can drive significant improvements in OEE. By leveraging Manufacturing Execution Systems (MES), users can create a unified PLC and HMI standardization strategy that ensures consistent performance measurement across diffrent production lines. For instance, a tier-one supplier employed standardized HMI interfaces across their stamping operations, which facilitated easier training for operators and improved response times to issues.This consistency in operation not only minimized setup errors but also enhanced the traceability of materials and processes, allowing for more informed decision-making and quicker responses to quality issues.As a result,the manufacturer observed a ample increase in OEE,reinforcing the importance of continuous monitoring and process improvement strategies in the automotive stamping sector.

To Conclude

optimizing Overall Equipment Effectiveness (OEE) in stamping plants is crucial for enhancing productivity and reducing operational costs. Implementing Ignition to calculate and visualize OEE brings substantial advantages, such as:

- Real-time Data Visualization: Gain instant insights into production metrics, improving decision-making processes.

- Root Cause Analysis: Quickly identify and address inefficiencies, minimizing downtime and production bottlenecks.

- Benchmarking: Establish performance standards that drive continuous improvement across production lines.

By integrating these features, you empower your teams to respond proactively to issues, standardize machinery performance, and ultimately improve output quality. For those looking to drive these advancements in their stamping operations, we invite you to explore comprehensive solutions with Innorobix. Let us assist you in harnessing the full potential of Ignition and MES systems. request a consultation or demo today to begin your journey towards a more efficient future.