Introduction: Integrating Okuma & Haas CNCs into MES without Custom code

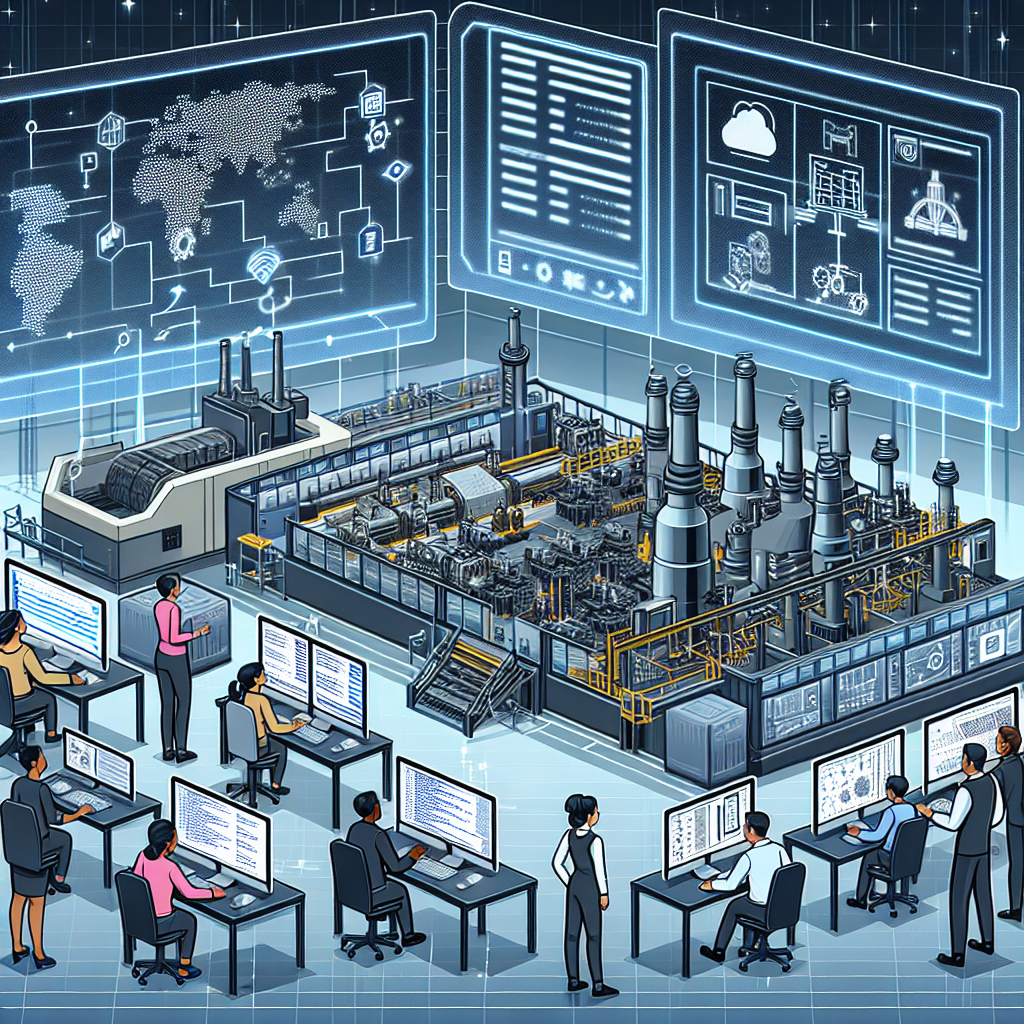

In today’s competitive manufacturing landscape, the need for seamless integration between machine tools and Manufacturing Execution Systems (MES) has never been more critical. As the demand for real-time data,efficiency,and productivity rises,manufacturers leveraging advanced CNC technologies from companies like Okuma and Haas stand to gain a meaningful edge.Though,the challenge frequently enough lies in the complexities of integration—especially when custom coding is involved.

This article will explore how manufacturers can effectively integrate Okuma and Haas CNCs into their MES platforms without the need for custom code. By leveraging built-in capabilities and industry standards such as MTConnect, businesses can enhance their shop floor visibility, streamline operations, and maximize return on investment (ROI).

Key Benefits of Integration without Custom Code:

- Reduced Development Time: Bypass the lengthy and costly process of developing custom code, allowing for quicker deployment of solutions.

- Standardized Data Exchange: Use the MTConnect standard to facilitate seamless interaction between machinery and MES,promoting interoperability irrespective of equipment manufacturer.

- Real-Time Monitoring: Achieve immediate visibility into machine status, performance metrics, and production rates, allowing for timely decision-making.

- Cost Efficiency: Minimize the total cost of ownership by reducing reliance on specialized programming and focusing on existing tools and platforms.

- Scalability: Easily integrate additional machines or upgrades in the future without the need to rewrite code, allowing your operations to grow alongside technological advancements.

Example Scenario:

Imagine a manufacturing facility that operates multiple Okuma and Haas CNC machines. With customary methods,integrating these machines into an MES without custom code would involve intense configurations and potentially extensive downtime.However, by utilizing the Innorobix MTConnect module, manufacturers can:

- Automatically capture critical operational data, such as spindle loads and downtime periods, without manual input.

- Trigger alerts for anomalies, enabling proactive measures before production is significantly impacted.

- Generate part counts in real-time, contributing to accurate inventory management and production planning.

By the end of this article, you will gain insight into the strategies, tools, and best practices necessary for integrating Okuma and haas CNCs into your MES while capitalizing on the inherent benefits of standardization, which elevates your operational efficiency and overall productivity.

Understanding the Communication Protocols of Okuma and Haas CNC Machines

Modern CNC machines, such as those from Okuma and Haas, utilize various communication protocols that play a crucial role in enabling seamless integration with Manufacturing Execution Systems (MES). Understanding these protocols is essential for effective data communication and monitoring without the need for custom coding. As an example, Okuma employs the OSP (open System Platform) communication system, which supports Ethernet-based protocols that facilitate real-time data exchange. This allows for the easy extraction of spindle load data and operational metrics,directly feeding into an MES for increased visibility of production efficiency. On the other hand, Haas machines often utilize RS-232 serial communication and Ethernet, which can be configured to output essential operational data, such as part counts and alerts for downtime, without requiring additional middleware or custom programming.

To effectively harness these communication protocols,manufacturers can implement middleware solutions that bridge the gap between CNC machines and MES systems. Using the Innorobix MTConnect module,users can capture machine data by simply configuring the networking settings within the CNC machine’s control panel. The key steps involve:

- Network Configuration: Setting up the CNC machine to communicate over a specified IP address and port for real-time data streaming.

- Data Endpoint Definition: Utilizing built-in MTConnect compatibility to define data sources, ensuring that critical data points—like spindle load and operational status—are correctly referenced.

- Data Validation: Implementing validation rules to ensure accuracy and integrity of real-time data sent to the MES.

this structured approach not only eliminates the need for extensive custom code but also facilitates swift integration that optimizes shop floor operations. The result is a robust setup allowing for timely issue detection, automated downtime logging, and improved decision-making based on reliable data gathered from the machines.

Leveraging MTConnect for Seamless Data Extraction and Integration

In today’s fast-paced manufacturing habitat, integrating CNC machines like Okuma and Haas into a Manufacturing Execution System (MES) is crucial for achieving streamlined operations and maximizing productivity. Utilizing MTConnect to capture machine data offers a standardized and vendor-agnostic way to facilitate this integration without the need for custom code. The Innorobix MTConnect module allows for real-time monitoring of essential parameters such as spindle load, coolant levels, and more. As an example, a shop using an Okuma Lathe can easily extract and analyze performance metrics through MTConnect, enabling data-driven decisions that enhance machine utilization and reduce operational costs.

By deploying MTConnect protocols, manufacturers can automatically log critical events and anomalies, such as unexpected increases in spindle load or unplanned downtime, directly into their MES. With minimal operator input required, this robust data collection can lead to significant ROI through reduced labor costs and improved error tracking. Additionally, part counting can be automated, eliminating guesswork and ensuring precision in inventory management. For instance, a Haas CNC machine coudl be equipped to log it’s production counts directly into the MES, providing manufacturers with valuable insights into production rates and helping better align supply chain logistics. As a result, the streamlined communication between machines and software not only enhances operational visibility but also fosters a culture of continuous improvement on the shop floor.

Implementing Automated Data Logging Features for Real-time Monitoring

Furthermore, real-time anomaly detection is streamlined through automated logging mechanisms. With continuous monitoring, your MES system can trigger alerts if real-time data deviates from established baselines—such as unexpected spikes in spindle load during a continuous production run. This capability allows operators and maintenance personnel to take proactive measures, reducing downtime and preventing potential machine failures. Some practical applications include:

- automated Downtime Logging: Automatically record when a machine goes off cycle, classifying the cause based on pre-set parameters.

- Part Counting: Utilize machine output data to automatically aggregate part counts without manual entry,ensuring accurate production metrics in real-time.

- Anomaly Alerts: Receive instant notifications via SMS or email when significant anomalies are detected, allowing for immediate investigation.

Maximizing Production Efficiency through MES Integration Strategies

Integrating Okuma and haas CNC machines into a Manufacturing Execution System (MES) can significantly enhance production efficiency, especially when leveraging the Innorobix MTConnect module. This seamless integration allows manufacturers to capture real-time data directly from machinery without the need for custom coding, reducing implementation time and costs. For instance, a leading precision machining shop utilizing Okuma CNC lathes was able to track spindle load variations during production. By automatically detecting deviations from predefined operational parameters, they identified inefficiencies such as tool wear and misalignment, which resulted in unplanned downtimes. In this scenario, preemptively addressing these anomalies increased their spindle uptime by over 25%, translating directly into improved throughput and reduced operational costs.

Furthermore, through the use of MES analytics and the Innorobix MTConnect module, shops can automate key processes like downtime logging and part counting without manual operator intervention. consider a scenario at a Haas CNC facility were operators previously needed to log downtimes manually. With integrated MES solutions, every time a machine halts, the automated system logs the duration and root cause based on real-time data collected from the machine’s telemetry. this leads to precise reporting and actionable insights that can inform maintenance schedules and operational strategies. Additionally, automated part counters provide accurate production statistics, empowering team leads to gauge productivity levels instantly, and make real-time decisions to reallocate resources or address bottlenecks. Ultimately, these integration strategies streamline operations, reduce human error, and enhance overall operational efficiency, driving significant ROI for shops across the board.

Final Thoughts

the integration of Okuma and Haas CNC machines into your Manufacturing Execution System (MES) is not only feasible without the need for custom coding but also essential for achieving operational excellence.By leveraging the capabilities of the Innorobix MTConnect module, manufacturers can unlock a wealth of data that enables effective monitoring, proactive maintenance, and enhanced productivity. Key takeaways from this integration process include:

- Seamless Communication: Using standardized MTConnect protocols allows for effortless data exchange between machines and the MES.

- Real-Time Monitoring: gain immediate insights into machine performance metrics such as spindle loads and cycle times, improving your decision-making processes.

- Anomaly detection and Alerts: Establish thresholds for key performance indicators, helping to identify and rectify issues before they lead to costly downtime.

- automated Downtime Logging: Eliminate the need for operator input by automating logging processes, providing accurate and reliable operational data.

- Increased ROI: By streamlining workflows and maximizing machine uptime, your investment in CNC technology can yield significantly higher returns.

We invite you to explore how Innorobix can transform your shop floor dynamics with our innovative solutions. For a personalized exhibition or to discuss specific integration strategies tailored to your operations, please do not hesitate to request a consultation. Together, we can drive your manufacturing efficiency to new heights.