Introduction to alarm Escalation Strategies for High-Speed Automotive Production

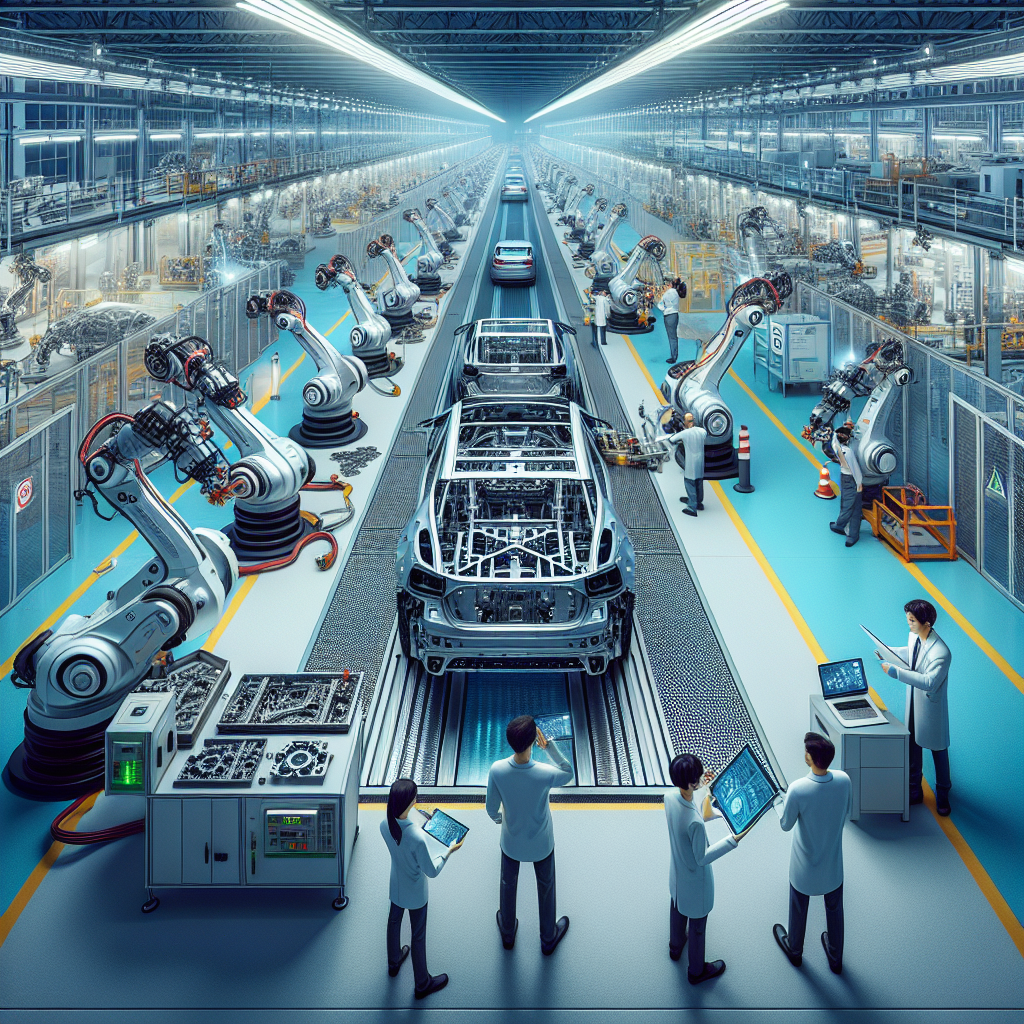

In the high-stakes environment of automotive manufacturing, producing vehicles efficiently while maintaining quality standards is paramount. With the advent of Industry 4.0, modern production lines have become equipped with increasingly complex machinery and advanced SCADA systems. Consequently,the management of alarms—arising from equipment anomalies,process deviations,or safety issues—becomes a critical component for minimizing downtime and ensuring optimal operational efficiency.

Alarm escalation strategies play a crucial role in addressing these challenges. Effective alarm management not only enhances the responsiveness of operators but also optimizes the overall production process. This article delves into the foundational concepts of alarm escalation and outlines strategies that can be employed to streamline operations within high-speed automotive production environments.

Key Benefits of Effective Alarm Escalation:

- Minimized Downtime: Rapid recognition and response to alarms can considerably reduce production interruptions.

- Improved Safety: Effective alarm handling reduces the risk of accidents by ensuring operators are alerted to potential hazards in a timely manner.

- Enhanced Productivity: By prioritizing alarms, teams can focus on critical issues that impact production, thus improving Overall Equipment Effectiveness (OEE).

- Data-Driven Decisions: Leveraging alarm data can guide continuous advancement efforts and inform future equipment investments.

this article will explore real-world use cases in the automotive sector that illustrate the impact of employing strategic alarm escalation protocols. We’ll discuss methodologies for implementing these strategies, the technology involved—such as MES systems and advanced SCADA setups like Ignition—and best practices for optimizing response times.Join us as we unlock the potential of alarm escalation strategies to create a more resilient and responsive automotive production environment.

Alarm Prioritization Techniques for Enhanced Response Efficiency

Effective alarm prioritization is crucial in high-speed automotive production environments, where a swift response can meen the difference between maintaining operational efficiency and facing costly downtimes. By categorizing alarms based on their severity and potential impact, production teams can allocate resources efficiently and ensure that critical issues are addressed promptly. As a notable example, a malfunction in a robotic assembly arm may trigger an alarm categorized as “High Priority,” while a minor fault in a labeling machine could be deemed “Low Priority.” This structured approach not only facilitates immediate intervention in critical scenarios but also enables teams to develop strategies for the prioritized resolution of less urgent alarms, reducing the overall impact on production schedules and enhancing operational reliability.

Incorporating advanced alarm management systems, such as Ignition’s Alarm Notification system, can further streamline this process. Using features such as filtering, grouping, and notification rules, organizations can customize alarm displays based on real-time operational data. For example, a well-known automotive manufacturer recently implemented a tiered response strategy within their MES that used data analytics to prioritize alarms based on past performance and failure rates. Alarms that historically led to prolonged downtime were given precedence, allowing operators to tackle root causes with greater urgency. This proactive approach not only optimized response times but also significantly improved the reliability of production lines, demonstrating that effective alarm prioritization is key to achieving lean and efficient operations in the competitive automotive sector.

Best Practices for Alarm Management in Automotive Manufacturing

Incorporating effective alarm management strategies is crucial for automotive manufacturers to maintain operational efficiency and ensure safety. Prioritizing alarms based on severity and the impact on production lines can significantly enhance response times and decision-making. For instance, in a high-speed automotive assembly plant producing engines, engineers implemented a tiered alarm system where critical alarms, such as those indicating a malfunction in the robotic welding cells, were highlighted and escalated to senior managers immediately. This practice minimized downtime by enabling a faster response to issues that could halt production or lead to defective assemblies. Additionally, integrating alarm management software with real-time data analytics helps in identifying patterns and predicting potential equipment failures before thay occur, allowing for proactive maintenance.

Establishing clear escalation protocols is equally vital in ensuring that alarms are addressed appropriately. For example, a leading automotive manufacturer deployed a multi-level escalation process for alarms triggered on the assembly line. Initially, frontline operators are alerted to non-critical alarms; if unresolved, the alarm escalates to a maintenance supervisor. if the situation persists, it moves up to higher management, ensuring that issues are addressed without unnecessary delay. Furthermore, conducting regular training on alarm importance and response procedures for operational staff can empower them to make informed decisions quickly. By emphasizing this process, the manufacturer experienced a notable decrease in alarm-related disruptions, resulting in improved Overall Equipment Effectiveness (OEE) metrics and a safer work environment.

Integrating Real-Time Data for Effective Alarm Escalation

Integrating real-time data into alarm escalation protocols can drastically improve responsiveness in high-speed automotive production environments. By leveraging SCADA systems like Inductive automation’s Ignition in conjunction with Manufacturing Execution Systems (MES), organizations can capture and relay production-critical data directly to operators and management. For example, a tier-one automotive supplier utilized real-time data to monitor key performance indicators (KPIs) across their production lines. When a machine’s efficiency dropped below a predefined threshold,the system automatically escalated an alarm,notifying not only the floor manager but also technicians qualified to address the specific issue,thereby reducing response time significantly.

Enhancing alarm escalation through real-time data allows companies to prioritize alerts more effectively. This can be achieved by categorizing alarms based on factors like severity, area of impact, and potential downtime duration. Implementation of triggered alarms ensures that critical issues receive immediate attention while lower-priority notifications are redirected to appropriate staff through performance metrics. Some manufacturers have also employed machine learning algorithms within their SCADA systems to develop predictive alerts based on historical performance data, allowing for more proactive maintenance strategies. Consequently, they have reduced reactive maintenance by up to 40%, translating into improved overall equipment effectiveness (OEE) and significant cost savings.

Case Studies: Successful Alarm Escalation Implementations in High-Volume Production

One notable implementation of alarm escalation in high-volume automotive production occurred at a leading manufacturer of electric vehicles. This facility faced frequent machine downtimes due to inadequate alarm response protocols, leading to significant production delays. By integrating a robust alarm escalation system via their MES, the company established a tiered alert system that notified operators and maintenance supervisors based on the severity of the alarm.As an example, minor alarms would first alert the machine operator via the HMI interface, while critical alarms triggered immediate notifications to both the maintenance team and production managers through SMS and email alerts. This proactive approach resulted in a 40% reduction in response time to critical failures and a measurable increase in overall equipment effectiveness (OEE).

Another successful case emerged from a conventional automotive parts manufacturer that deployed an alarm management solution to enhance real-time decision-making on the shop floor. By utilizing Ignition’s powerful dashboard capabilities,they visualized alarms in a user-pleasant format that highlighted key metrics and trends. this allowed operators to prioritize their responses effectively.The real-time data also enabled the formulation of more accurate maintenance schedules, ensuring that equipment was serviced before failures could occur. Additionally, by categorizing alarms into actionable items, the facility reported a 30% decrease in unnecessary alarm noise and a sustained improvement in production throughput, showcasing the pivotal role of alarm escalation in maintaining high-speed production lines.

Wrapping Up

effective alarm escalation strategies are critical for maintaining operational efficiency in high-speed automotive production environments.By implementing a structured approach to alarm management, manufacturers can significantly minimize downtime, enhance response times, and improve overall system reliability. Key takeaways include:

- Prioritization of Alarms: Focus on critical alarms that directly impact production and safety, ensuring rapid response.

- Integration with SCADA and MES: Utilize Ignition and MES systems for real-time monitoring and automatic escalation protocols, thereby reducing human error and delays.

- Continuous improvement: Implement regular reviews and updates to alarm systems based on performance metrics and incident analysis, fostering a culture of proactive management.

- Training and Empowerment: Equip operators with knowledge and tools to respond effectively to alarms, enhancing their problem-solving capabilities.

To explore tailored solutions that integrate these best practices, or to request a consultation/demo with Innorobix, please visit our website. Our team of experts is ready to assist you in optimizing your automotive production processes and elevating your operational efficiency.