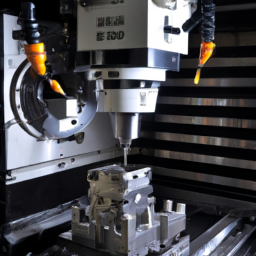

In the bustling heart of modern manufacturing, precision and efficiency reign supreme. Yet, amidst the rhythmic hum of CNC machines and the orchestration of complex workflows, an often-overlooked hero emerges: data. From the subtle nuances of machine performance to the intricate dance of operational metrics, data holds the key to unlocking unprecedented levels of productivity. Enter MTConnect, a game-changer in the realm of CNC data collection. By bridging the gap between disparate systems and streamlining the flow of information, MTConnect integration simplifies the formidable task of harnessing CNC data. Join us as we delve into how this innovative protocol is transforming the landscape of manufacturing, turning data into a wellspring of actionable insights and operational excellence.

Understanding the Basics of MTConnect and Its Role in CNC Data Collection

MTConnect is an open, royalty-free standard designed to foster greater interoperability between manufacturing equipment, devices, and software applications. By leveraging MTConnect, manufacturers can achieve seamless data communication across diverse CNC machines and systems. This standard uses XML and HTTP to structure and transport data, providing a common language for disparate devices to communicate effectively. With MTConnect, the data collected from CNC machines becomes more accessible and actionable, leading to improved operational efficiency and reduced downtime.

Integrating MTConnect into your CNC data collection process offers numerous benefits. Some of the key advantages include:

-

- Enhanced Data Visibility: Real-time monitoring of machine performance and status.

-

- Improved Decision-Making: Access to accurate and timely data enables better operational decisions.

-

- Increased Efficiency: Streamlined data collection reduces the need for manual data entry and minimizes errors.

-

- Scalability: Easily scalable to accommodate additional machines and devices as your production grows.

By integrating MTConnect, manufacturers can transform their CNC operations, leading to more informed decisions and optimized production processes.

Leveraging Real-Time Data: How MTConnect Enhances Operational Efficiency

In the fast-paced world of CNC machining, the ability to access real-time data is a game-changer. MTConnect, an open-standard communication protocol, stands at the forefront of this revolution. By seamlessly integrating with your CNC machines, MTConnect enables the continuous flow of data, offering invaluable insights into machine performance and operational efficiency. Through the use of standardized data formats, MTConnect eliminates the complexities associated with proprietary systems, allowing for a more streamlined and straightforward data collection process. This not only reduces downtime but also enhances predictive maintenance capabilities, ensuring that your operations run smoothly and efficiently.

With MTConnect, the benefits extend beyond mere data collection. The protocol facilitates enhanced interoperability between different machines and systems, allowing for a more cohesive and unified manufacturing environment. Key advantages include:

-

- Real-Time Monitoring: Instantly track machine status, performance metrics, and production data.

-

- Improved Decision-Making: Leverage accurate, up-to-the-minute information to make informed operational decisions.

-

- Reduced Downtime: Quickly identify and address issues before they escalate, minimizing interruptions.

-

- Enhanced Maintenance: Predictive maintenance schedules based on real-time data reduce unexpected breakdowns.

By harnessing the power of MTConnect, Innorobix Automation empowers manufacturers to achieve unprecedented levels of efficiency and productivity, transforming the way they approach CNC data collection and operational management.

Integrating MTConnect with Existing CNC Systems: Best Practices and Common Pitfalls

Integrating MTConnect with your existing CNC systems can significantly streamline data collection, but it requires a strategic approach to avoid common pitfalls. One of the best practices is ensuring compatibility between your CNC machines and the MTConnect standard. Conducting a thorough compatibility assessment will help identify any potential issues that could disrupt data flow. Additionally, updating firmware and software on your CNC machines to the latest versions can mitigate compatibility issues and enhance performance. It’s also crucial to document your existing system architecture meticulously, as this will aid in mapping out the integration process and identifying critical connection points.

Common pitfalls often stem from insufficient planning and lack of stakeholder involvement. Involving key stakeholders from the outset ensures that all requirements and constraints are considered, reducing the risk of unforeseen challenges. Another frequent issue is underestimating the network infrastructure requirements. MTConnect can generate substantial data traffic, so it’s essential to evaluate and upgrade your network infrastructure if necessary to handle the increased load. Lastly, testing the integration extensively in a controlled environment before full-scale implementation can help identify and resolve issues early, ensuring a smoother transition.

Future-Proofing Your Workshop: The Long-Term Benefits of MTConnect Integration

In an era where precision and efficiency are paramount, integrating MTConnect into your CNC operations is more than just a technological upgrade—it’s a strategic move toward future-proofing your workshop. MTConnect enables seamless data collection and communication between diverse manufacturing devices and software, offering a unified language that simplifies complex processes. This standardization facilitates real-time monitoring and analytics, providing valuable insights that drive productivity and operational efficiency. Imagine having the capability to track machine performance, predict maintenance needs, and optimize workflow without manual intervention. The benefits of such integration are not just immediate but extend far into the future, ensuring that your workshop remains agile and competitive in an ever-evolving market.

By adopting MTConnect, you are setting the stage for a more resilient and adaptable manufacturing environment. Here are some long-term advantages you can expect:

-

- Enhanced Interoperability: Connect and communicate with a wide range of devices and software systems effortlessly.

-

- Scalability: Easily expand your operations without worrying about compatibility issues.

-

- Cost Efficiency: Reduce downtime and maintenance costs through predictive analytics.

-

- Data-Driven Decisions: Leverage real-time data to make informed decisions that optimize production.

-

- Future Readiness: Stay ahead of industry trends with a system designed to evolve with technological advancements.

Incorporating MTConnect into your CNC setup is not just about keeping pace with current technology, but about laying a robust foundation for continuous improvement and innovation.

Q&A

Q: What is CNC data collection, and why is it important?

A: CNC data collection refers to the process of gathering and analyzing data from Computer Numerical Control (CNC) machines. This data can include information about machine performance, usage, maintenance needs, and production output. The importance of CNC data collection lies in its ability to enhance operational efficiency, reduce downtime, optimize machine usage, and ultimately improve the overall productivity and profitability of manufacturing processes.

Q: What is MTConnect, and how does it relate to CNC data collection?

A: MTConnect is an open, royalty-free standard that facilitates the communication and interoperability between manufacturing equipment and software applications. It enables the seamless collection and exchange of data from various machines and devices on the shop floor. In the context of CNC data collection, MTConnect acts as a bridge that standardizes the data output from different CNC machines, making it easier to gather, analyze, and utilize this information across different platforms and systems.

Q: How does MTConnect simplify the process of CNC data collection?

A: MTConnect simplifies CNC data collection by providing a standardized protocol for data exchange. This eliminates the need for custom interfaces and proprietary software, which can be cumbersome and expensive to develop and maintain. With MTConnect, manufacturers can easily integrate data from different CNC machines and other equipment, regardless of the manufacturer or model, into a unified system. This standardization reduces complexity, saves time, and lowers costs associated with data collection and analysis.

Q: Can you provide an example of how MTConnect integration can benefit a manufacturing operation?

A: Certainly! Imagine a manufacturing facility with multiple CNC machines from different manufacturers. Traditionally, each machine might require a unique data extraction method, leading to a fragmented and inefficient data collection process. By integrating MTConnect, the facility can standardize the data output from all these machines. This unified data stream can then be fed into a centralized monitoring system, allowing operators to track performance, identify issues, and optimize processes in real-time. For example, if a machine starts showing signs of wear, the system can alert maintenance staff before a breakdown occurs, thereby reducing downtime and maintenance costs.

Q: What are the steps involved in implementing MTConnect for CNC data collection?

A: Implementing MTConnect for CNC data collection involves several key steps:

-

- Assessment: Evaluate the current state of your CNC machines and data collection methods to determine compatibility with MTConnect.

-

- Hardware and Software Setup: Install MTConnect-compatible hardware adapters and software agents on your CNC machines.

-

- Configuration: Configure the MTConnect devices to ensure they are correctly communicating with your central data collection system.

-

- Integration: Integrate the standardized data from MTConnect into your existing monitoring and analysis software.

-

- Validation and Testing: Perform thorough testing to ensure data is being accurately collected, transmitted, and analyzed.

-

- Training: Train staff on how to use the new system and interpret the data for maximum benefit.

Q: Are there any challenges associated with integrating MTConnect into an existing manufacturing setup?

A: While MTConnect offers numerous benefits, there can be challenges in its integration. These may include compatibility issues with older equipment, the initial cost of upgrading hardware and software, and the need for technical expertise to set up and maintain the system. Additionally, there might be a learning curve for staff to fully utilize the new data collection capabilities. However, these challenges are often outweighed by the long-term gains in efficiency, productivity, and cost savings.

Q: What resources are available for manufacturers looking to implement MTConnect?

A: Manufacturers can access a variety of resources to aid in the implementation of MTConnect, including:

-

- MTConnect Institute: The official website offers comprehensive documentation, guidelines, and support.

-

- Industry Forums and User Groups: Online communities where users share experiences, tips, and best practices.

-

- Consultants and Integrators: Professional services that specialize in MTConnect implementation and can provide tailored solutions.

-

- Training Programs: Workshops and courses that cover the technical aspects of MTConnect and how to leverage it effectively.

By leveraging these resources, manufacturers can streamline the integration process and maximize the benefits of MTConnect for their CNC data collection needs.

In Retrospect

As the landscape of manufacturing continues to evolve, the integration of MTConnect for CNC data collection stands as a beacon of efficiency and precision. By streamlining processes and enhancing data visibility, MTConnect opens the door to a new era of operational excellence.

At Innorobix Automation, we’re dedicated to helping you navigate this transformative journey. Our expertise in automation and data integration is designed to empower your operations, ensuring you harness the full potential of MTConnect. Whether you’re taking your first steps or looking to optimize an established system, we’re here to support you every step of the way.

Ready to simplify your CNC data collection and elevate your manufacturing capabilities? Reach out to Innorobix Automation and let’s embark on this innovation-driven path together. Your next breakthrough is just a conversation away.