Autonomous mobile robots (AMRs) and Ignition are two technologies that are transforming the manufacturing industry in Canada and around the world. By automating tasks such as material handling and transportation, AMRs can increase efficiency and reduce costs, while Ignition’s industrial automation platform can help to streamline operations and improve visibility into production processes.

To learn more about the benefits and best practices for integrating AMRs and Ignition in the Canadian manufacturing industry, we sat down with expert to get his insights.

Q: How can AMRs and Ignition be used together in the manufacturing industry?

A: AMRs and Ignition can be used together to automate and streamline manufacturing processes. AMRs can handle tasks such as material handling and transportation, while Ignition’s industrial automation platform can be used to monitor and control production processes, track production data, and provide real-time visibility into the plant’s operations. By integrating these technologies, manufacturers can increase efficiency, reduce costs, and improve the overall performance of their operations.

Q: What are some best practices for integrating AMRs and Ignition in a manufacturing plant?

A: Some best practices for integrating AMRs and Ignition in a manufacturing plant include:

- Identifying the tasks that the AMRs will be responsible for and defining the requirements for each task.

- Choosing the right AMR for the tasks at hand, taking into consideration factors such as the size and weight of the objects to be transported, the layout of the plant, and the operating environment.

- Mapping out the routes that the AMRs will follow, taking into account any obstacles or hazards that they may encounter.

- Installing any necessary infrastructure, such as sensors, beacons, or charging stations, to support the operation of the AMRs.

- Conducting thorough testing and fine-tuning of the AMR system to ensure that it is functioning correctly and meeting the requirements of the tasks.

- Training the staff on how to use and maintain the AMR system, including how to troubleshoot any issues that may arise.

By following these best practices, manufacturers can successfully integrate AMRs and Ignition in their plant and realize the full benefits of these technologies.

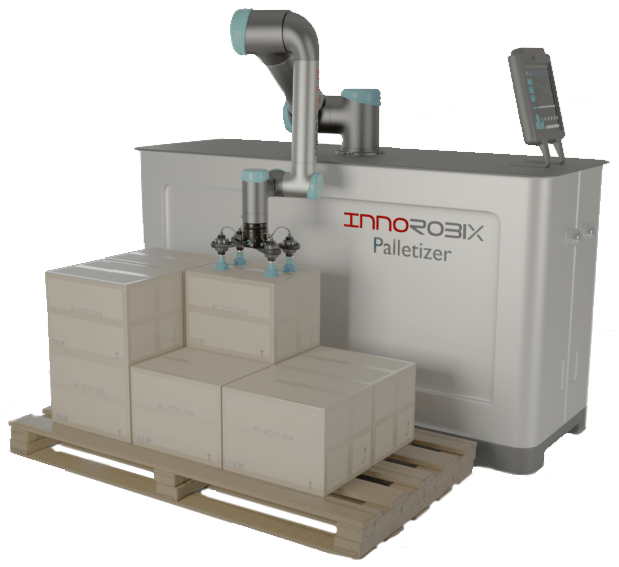

If you’re interested in learning more about how MiR AMRs can benefit your manufacturing process, don’t hesitate to reach out to Innorobix. Our team of experts can help you plan and execute a successful AMR deployment, maximizing the efficiency and benefits of these innovative technologies.