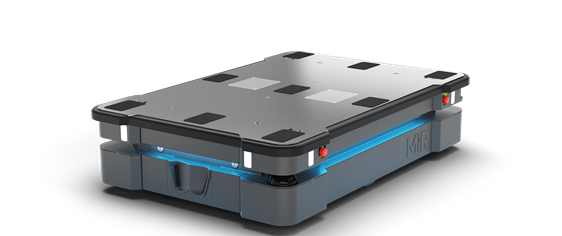

In the sprawling labyrinth of modern warehouses, where towering shelves brim with goods and the hum of activity is perpetual, a silent revolution is unfolding. Autonomous Mobile Robots, or AMRs, glide seamlessly through the intricate maze, orchestrating a ballet of precision and efficiency. These digital custodians, equipped with an array of sophisticated sensors and algorithms, navigate the complex terrain with an almost uncanny intelligence. But how do these robotic marvels chart their course amidst the chaos, avoiding obstacles and ensuring timely deliveries? Join us as we delve into the fascinating world of AMR navigation, unraveling the technological tapestry that empowers these machines to transform the very nature of warehousing.

Mapping the Maze: Understanding AMR Navigation Systems

Autonomous Mobile Robots (AMRs) are rapidly transforming warehouse operations with their sophisticated navigation systems. These systems leverage a mix of sensors, cameras, and advanced algorithms to chart their paths within complex environments. Lidar sensors play a pivotal role by emitting laser beams to measure distances to surrounding objects, creating real-time 3D maps. Paired with vision cameras, AMRs can recognize landmarks and obstacles, enhancing their spatial awareness. This combination of technologies allows the robots to make split-second decisions, adapting to dynamic changes in the warehouse layout. Additionally, inertial measurement units (IMUs) help the robots maintain balance and direction, ensuring precise navigation even on uneven surfaces.

Another crucial element in AMR navigation is the use of Simultaneous Localization and Mapping (SLAM) algorithms. SLAM enables robots to build and update maps of their environment while keeping track of their location within it. This dual capability is essential for AMRs to operate smoothly in ever-changing warehouse settings. Path planning algorithms further optimize the robots’ routes, taking into account factors such as traffic congestion, priority tasks, and battery levels. These algorithms ensure that AMRs not only reach their destinations efficiently but also avoid collisions and minimize downtime. As a result, warehouses can achieve higher productivity and better resource management, thanks to the intelligent navigation systems of AMRs.

Sensors and Software: The Technology Behind Precision

Autonomous Mobile Robots (AMRs) rely on an intricate blend of advanced sensors and cutting-edge software to navigate the complex environment of a warehouse with remarkable precision. These robots are equipped with various sensors such as LiDAR, ultrasonic sensors, cameras, and infrared sensors. Each type of sensor plays a unique role in building a comprehensive understanding of the robot’s surroundings. For instance, LiDAR creates real-time 3D maps, while cameras capture visual data to identify obstacles and pathways. Ultrasonic and infrared sensors are crucial for detecting objects in close proximity, ensuring that the AMR can make split-second decisions to avoid collisions.

The software that drives these robots is equally sophisticated, employing algorithms like Simultaneous Localization and Mapping (SLAM) and path planning. SLAM enables the AMR to construct and update maps of its environment while simultaneously tracking its own location. Path planning algorithms calculate the most efficient routes to follow, taking into account dynamic obstacles and real-time updates from sensors. This synergy between hardware and software allows AMRs to perform tasks with high accuracy and efficiency, revolutionizing the way warehouses operate. The integration of machine learning further enhances their capabilities, enabling continuous improvement in navigation and task execution.

Obstacle Management: How AMRs Handle Dynamic Environments

In the bustling environment of a warehouse, Autonomous Mobile Robots (AMRs) showcase their ability to adapt and thrive amidst constant changes. Leveraging advanced sensor arrays, these intelligent machines detect obstacles in real-time, allowing them to navigate around unexpected barriers seamlessly. LIDAR, ultrasonic sensors, and cameras work in unison to create a comprehensive map of their surroundings, ensuring that even the smallest object is identified and avoided. This dynamic obstacle management is further augmented by sophisticated algorithms that predict the movement of objects and personnel, enabling the AMRs to make split-second decisions and reroute their paths effectively.

Moreover, AMRs are equipped with machine learning capabilities that allow them to analyze past navigation experiences and optimize future routes. Whether it’s a fallen box, a sudden human presence, or a newly placed pallet, these robots learn to handle it all with increasing efficiency. Key features contributing to their adaptability include:

-

- Real-time data processing: Continuously updating their navigation maps based on live data.

-

- Predictive path planning: Anticipating the movement of dynamic obstacles to minimize disruptions.

-

- Collaborative intelligence: Sharing information with other AMRs to enhance overall operational efficiency.

This synergy of cutting-edge technology and intelligent design ensures that AMRs can maintain productivity and safety in the ever-changing landscape of a warehouse.

Optimizing Routes: Strategies for Efficient AMR Navigation

Automated Mobile Robots (AMRs) are revolutionizing warehouse logistics by leveraging a combination of advanced sensors, real-time data processing, and sophisticated algorithms. Laser-based LiDAR sensors create detailed maps of the warehouse environment, enabling AMRs to navigate with pinpoint accuracy. Additionally, camera systems and ultrasonic sensors aid in obstacle detection, ensuring that these robots can deftly maneuver around sudden impediments. By continuously updating their internal maps, AMRs can adapt to changes in the warehouse layout, such as the arrival of new inventory or temporary construction zones.

To further optimize their routes, AMRs utilize machine learning algorithms that analyze historical data to predict the most efficient paths. These algorithms take into account various factors, including traffic patterns, inventory locations, and energy consumption. By dynamically adjusting their routes, AMRs can minimize travel time and reduce wear and tear on their components. Furthermore, collaborative multi-robot systems allow AMRs to communicate with one another, ensuring that they can coordinate their movements and avoid potential bottlenecks. This level of intelligent navigation not only enhances operational efficiency but also contributes to a safer and more organized warehouse environment.

Q&A

Q: How do Autonomous Mobile Robots (AMRs) navigate in a warehouse?

A: Great question! AMRs are like the unsung heroes of modern warehouses, silently gliding through aisles, efficiently transporting goods from one place to another. But how do they know where to go and how to get there?

Q: Do AMRs use GPS like our cars do?

A: Not exactly. GPS is fantastic for outdoor navigation, but it doesn’t work well indoors due to the lack of a clear line of sight to satellites. Instead, AMRs rely on a combination of sensors and software to find their way around.

Q: What kind of sensors do they use?

A: AMRs are typically equipped with a variety of sensors, including LiDAR (Light Detection and Ranging), cameras, ultrasonic sensors, and sometimes infrared sensors. LiDAR is particularly important because it creates detailed 3D maps of the warehouse environment by emitting laser beams and measuring their reflections.

Q: How do these sensors help in navigation?

A: The sensors constantly gather data about the robot’s surroundings. For instance, LiDAR helps in mapping out the environment, while cameras and ultrasonic sensors detect obstacles. The data from these sensors is processed by the robot’s onboard computer to create a real-time map of the warehouse. This map helps the AMR determine its location and plan the best path to its destination.

Q: So, do AMRs follow a fixed path or can they adapt?

A: One of the coolest things about AMRs is their flexibility. Unlike traditional automated guided vehicles (AGVs), which follow fixed paths marked by magnetic strips or wires, AMRs can adapt to changes in the environment. If an obstacle appears in their way, they can dynamically re-route themselves to avoid it.

Q: How do they decide the best route to take?

A: AMRs use sophisticated algorithms to calculate the most efficient route. These algorithms take into account various factors like distance, current traffic in the warehouse, and even the battery level of the robot. The goal is to optimize efficiency while ensuring safety.

Q: What happens if two AMRs are on a collision course?

A: Good question! AMRs are designed with collision avoidance systems. They communicate with each other and the central warehouse management system to coordinate their movements. If two AMRs are on a potential collision course, they’ll negotiate to decide who should yield or take an alternate path.

Q: Can AMRs work in any type of warehouse?

A: While AMRs are incredibly versatile, they’re best suited for warehouses that are designed with their capabilities in mind. This means having clear, wide aisles and minimal clutter. However, advances in technology are continually expanding the environments where AMRs can operate effectively.

Q: Are humans still needed in a warehouse with AMRs?

A: Absolutely! While AMRs handle repetitive and physically demanding tasks, humans are still crucial for more complex decision-making, maintenance of the robots, and tasks that require a level of dexterity and problem-solving that robots haven’t yet mastered.

Q: What’s the future of AMR technology in warehouses?

A: The future looks bright! We can expect to see even more intelligent and versatile AMRs with improved sensors, better algorithms, and enhanced collaboration capabilities. As AI and machine learning continue to evolve, AMRs will become even more efficient, making warehouses smarter and more productive.

So, the next time you receive a package swiftly delivered from a warehouse, there’s a good chance an AMR played a key role in getting it to you. Fascinating, isn’t it?

In Conclusion

As the world of logistics continues to evolve, the role of Autonomous Mobile Robots (AMRs) in warehouse navigation becomes ever more pivotal. These technological marvels, with their sophisticated sensors, intelligent algorithms, and seamless integration capabilities, are redefining efficiency and precision in warehouse operations. From mapping vast spaces to avoiding obstacles and optimizing routes, AMRs are not just tools but partners in productivity.

Curious to delve deeper into how AMRs could revolutionize your warehouse operations? At Innorobix Automation, we’re passionate about pioneering the future of automation. Our team of experts is ready to guide you through the intricacies of AMR technology and tailor solutions that meet your unique needs.

Reach out to us today, and let’s explore how innovation can drive your success. Your journey towards a smarter, more efficient warehouse begins now.