Using SCADA to Identify Underutilized CNC Assets

In the increasingly competitive landscape of modern manufacturing, optimizing machine utilization is paramount. For CNC shops, even minor improvements in asset utilization can lead to meaningful enhancements in productivity, cost savings, and overall efficiency.Supervisory Control and Data Acquisition (SCADA) systems play a crucial role in enabling manufacturers to gain real-time insights into their CNC assets, identifying underutilized resources that hinder operational excellence.

This article will delve into the methodologies and technologies that facilitate the identification of underutilized CNC assets using SCADA systems. By leveraging advanced data analytics and real-time monitoring, manufacturers can pinpoint inefficiencies and implement corrective actions that contribute to maximizing the return on investment (ROI).

key Topics covered:

- Understanding SCADA Architecture:

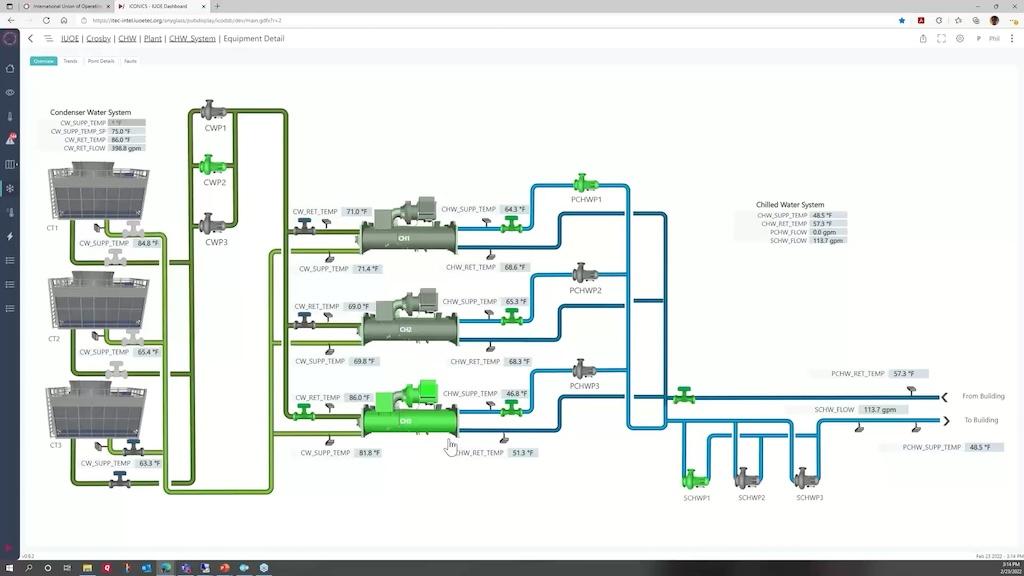

- Overview of SCADA components—sensors, controllers, and visualization platforms.

– The role of SCADA in aggregating real-time data from CNC machines.

- Identifying Key Performance Indicators (KPIs):

– Selecting relevant KPIs such as machine utilization rates, spindle load percentage, and down-time duration.

- Setting benchmarks for optimal performance against ancient data.

- Data Analytics for Actionable Insights:

– Utilizing data visualization tools within SCADA systems to generate real-time dashboards.

– Examples of visual analytics that highlight underused machines or portions of the production cycle.

- Implementing Alarm Systems for Anomaly Detection:

- Configuring SCADA alarms to notify operators of significant deviations from standard performance.

- Case studies demonstrating cost reductions achieved through rapid response to alerts.

- Integrating SCADA with Existing MES and ERP Solutions:

– Enhancing data flow between SCADA systems and Manufacturing Execution systems (MES).

- Exploring how seamless integration drives continuous enhancement and strategic resource allocation.

As we explore the capabilities of SCADA in this context, the goal is to empower manufacturing leaders with the knowledge and tools necessary to unlock the full potential of their CNC assets, driving them towards a more optimized, data-driven production habitat. Whether you are aiming to enhance operational efficiency, reduce costs, or increase output, harnessing SCADA systems effectively is the key to staying competitive in today’s fast-paced market.

identifying Underutilization Through Real-Time Data Monitoring and Analysis

In the fast-paced world of CNC machining, the ability to identify underutilized assets can dramatically improve operational efficiency and profitability. By implementing a SCADA system integrated with the Innorobix MTConnect module, manufacturers can monitor key performance indicators (KPIs) in real time. As an example, a manufacturer may discover that a high-speed milling machine is frequently enough sitting idle during peak production hours due to ineffective scheduling or unexpected machine downtime. By capturing real-time spindle load and operational data, shop managers can pinpoint specific times when the machine is underutilized and apply targeted strategies such as work order prioritization or additional employee training for setup. This proactive approach ensures that machinery operates closer to its capacity, maximizing return on investment (ROI).

Utilizing SCADA not only helps in identifying these inefficiencies but also in visualizing trends over time. Managers can set alerts for abnormal drops in productivity, enabling immediate investigation and remediation. Consider a scenario where a CNC lathe consistently shows a spindle load drop and low part count at certain times of the day.By analyzing the historical data collected through the SCADA system, the shop floor team can identify underlying issues such as outdated tooling or improper programming, which can be addressed to re-establish optimal performance levels. Key features of this analysis include:

- Visual Dashboards: Display real-time data for quick assessments of machine utilization.

- Automated Alerts: Notifications for anomalies such as prolonged machine idling or unexpected drops in spindle load.

- Trend Analysis: historical data usage patterns to inform long-term scheduling and maintenance plans.

Leveraging SCADA Systems for Comprehensive Asset Performance Metrics

In today’s competitive manufacturing landscape, leveraging SCADA systems goes beyond basic monitoring; it enables organizations to gain deep insights into asset performance metrics. Such as, a mid-sized machine shop utilized SCADA to track the spindle load of its CNC machines in real-time while employing the Innorobix MTConnect module. By analyzing data patterns, the shop identified that one of its key CNC lathes consistently operated at only 40% of its capacity during peak hours. This revelation prompted management to conduct further investigations into operational practices, revealing that improper scheduling and tooling setup inefficiencies were contributing to underutilization. Armed with these insights, they adjusted workflows and optimized scheduling, leading to a significant increase in machine availability and throughput.

Moreover, SCADA systems can also automate downtime logging based on real-time performance indicators such as spindle load and cutting speed. By setting thresholds on acceptable operational metrics, alerts can be generated if deviations occur. For instance, a large aerospace manufacturer used this automated detection feature to quantify downtime associated with specific machinery. Whenever a machine’s spindle load dropped below a designated level, the SCADA system automatically timestamped the event and categorized the reason for the drop—be it tool wear or mechanical failure. Over time, these automatic logs generated a rich dataset, allowing the company to effectively pinpoint recurring issues and drive targeted improvements, ultimately enhancing overall equipment effectiveness (OEE) and leading to better ROI through reduced downtime and increased production capacity.

Implementing Predictive Maintenance to Enhance CNC Machine Utilization

Implementing predictive maintenance solutions using SCADA systems can significantly enhance CNC machine utilization by leveraging real-time data insights to prevent unexpected failures. For example, integrating the Innorobix MTConnect module allows manufacturers to monitor key performance indicators such as spindle load, temperature fluctuations, and cycle times. This continuous data stream enables operators to set thresholds that trigger alerts when a machine operates outside its normal parameters. As a case in point, a leading aerospace components manufacturer applied predictive analytics to their CNC lathes, which led to a reduction in downtime by 30% and a notable increase in overall equipment effectiveness (OEE). They utilized detailed machine history data to forecast maintenance needs, allowing for timely interventions that aligned with production schedules, rather than unexpected breakdowns.

Furthermore, predictive maintenance not only reduces downtime but also optimizes the entire manufacturing process through better asset utilization. By employing the Innorobix MTConnect module, shops can automatically log and analyze downtime occurrences without requiring operator input. Key benefits include:

- Enhanced visibility into machine performance and health

- Data-driven decision making that prioritizes urgent maintenance tasks

- Real-time anomaly detection that catches potential issues before they escalate

- Reliable part counting and automated reporting to meet production goals

Through the integration of maintenance data with an MES system,businesses can create actionable reports that provide insights into machine utilization trends,ultimately contributing to more efficient planning and resource allocation. This comprehensive approach allows organizations to make informed choices about machine usage and lifecycle management, thus maximizing ROI and driving continuous improvement across the shop floor.

Optimizing Production Efficiency with Actionable Insights and Machine Learning

By leveraging the capabilities of SCADA and the Innorobix MTConnect module, manufacturers can gain in-depth visibility into the performance of their CNC assets, thereby identifying areas ripe for improvement. Actionable insights derived from real-time data analytics enable shops to pinpoint underutilized machines that may not be operating at their full potential. As a notable example,a large metal fabrication shop noticed that one of their CNC lathes was consistently underperforming,achieving only 60% of its capacity. Through the integration of SCADA systems with machine-learning algorithms, the shop was able to analyze spindle load, cycle times, and production history. The data highlighted that specific tooling setups were rarely optimized, leading to needless idle time. Consequently, targeted training and process adjustments were implemented, ultimately improving utilization rates significantly, leading to a potential 15% increase in overall throughput.

furthermore, predictive maintenance powered by machine learning algorithms can mitigate risks associated with machine failures. Armed with historical operating data, shops can predict when a machine is likely to experience a fault and preemptively schedule maintenance before any unplanned downtime occurs. Such as, a plastic injection molding facility integrated their SCADA with MTConnect, allowing them to monitor not only machine performance but also environmental conditions such as temperature and humidity. The system detected deviations from established norms, allowing operators to take corrective actions proactively. Consequently, the facility managed to reduce unplanned downtime by 20%, optimizing workflow and enhancing production efficiency. With the continuous feedback loop established through data analytics, companies can continually refine their operations, thereby maximizing ROI and achieving lasting growth in a competitive landscape.

The way Forward

leveraging SCADA systems to identify underutilized CNC assets presents a significant opportunity for manufacturers to enhance operational efficiency and maximize returns on capital investment. By implementing advanced monitoring solutions, businesses can:

- Accurately monitor spindle load to understand machine utilization rates more effectively.

- Detect anomalies in machine performance early,leading to proactive maintenance and reduced downtime.

- Automate downtime logging, minimizing manual input and improving data accuracy for better decision-making.

- Create part counters automatically without operator intervention, thus ensuring accurate tracking of production output in real-time.

These key takeaways can drive substantial improvements in production optimization, leading to enhanced profitability. If you’re looking to harness the power of data-driven practices in your operations, we invite you to explore the advanced capabilities of the Innorobix MTConnect module. For a more tailored approach, please request a consultation or schedule a demo to see firsthand how our solutions can transform your shop floor performance.