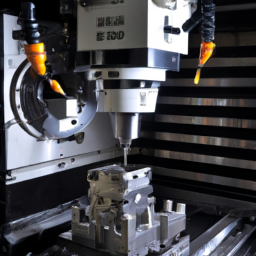

In the bustling world of modern manufacturing, precision and efficiency are paramount. The unseen maestros orchestrating this symphony of productivity are often the CNC (Computer Numerical Control) machines, whose silent diligence crafts the very nuts and bolts of today’s innovations. Yet, behind the scenes, a revolution is taking shape—one that promises to elevate the transparency and optimization of CNC operations. Enter the realm of Ignition and MTConnect, powerful tools that offer a window into the soul of manufacturing machinery. This article embarks on a journey to explore how these technological marvels converge, shedding light on the art of optimizing CNC monitoring. Through the lens of Ignition and MTConnect insights, we will uncover new possibilities for refined control and enhanced productivity, driving the industry forward into an era of unprecedented capability.

Enhancing Data Acquisition with Ignition Integration

At Innorobix Automation, we harness the power of Ignition software and the versatile MTConnect protocol to deliver robust data acquisition solutions for CNC monitoring. The convergence of these technologies ensures seamless integration and unparalleled operational insights, allowing manufacturers to leverage real-time data for optimized performance. By integrating Ignition with MTConnect, data from various CNC devices is effectively captured, monitored, and analyzed, providing a comprehensive view of the entire manufacturing process.

-

- Real-Time Data Acquisition: Instantly access CNC machine statuses and performance metrics.

-

- Enhanced Analytics: Utilize detailed reports and visualizations for data-driven decision making.

-

- Interoperability: Seamlessly integrate with existing systems for a cohesive workflow.

Ignition’s powerful tools enable intuitive dashboards and sophisticated analytics, facilitating a deeper understanding of machine operations and maintenance needs. The flexibility of MTConnect ensures future scalability, accommodating new machines and processes as they are integrated. With this dual approach, downtime is minimized and productivity is maximized, elevating the overall efficiency of CNC operations.

Leveraging MTConnect for Real-Time Analytics

MTConnect, an open, royalty-free protocol, transforms how manufacturers and plant managers grasp the live status of their CNC machines. By integrating this standardized communication framework with Ignition, businesses can seamlessly harness real-time data analytics to optimize operations. The advantages of using MTConnect in conjunction with Ignition are undeniable:

-

- Enhanced Visibility: Detailed insights into machine performance and uptime.

-

- Proactive Maintenance: Anticipating issues before they cause downtime.

-

- Streamlined Operations: Real-time data for informed decision-making, reducing production bottlenecks.

Consider a practical scenario where MTConnect feeds real-time data directly into Ignition’s powerful analytics engine. Using these actionable insights, maintenance schedules can be dynamically adjusted, minimizing disruptions and maximizing throughput. Embrace MTConnect with Ignition to drive your CNC monitoring to new heights.

Strategies to Improve CNC Efficiency Through Monitoring

By leveraging MTConnect and Ignition, you can transform your CNC operations into a robust data-driven ecosystem. These technologies provide detailed, real-time insights into machine performance, allowing for strategic decision-making and immediate corrective actions. Some of the primary strategies include system integration that harmonizes machine tools with manufacturing processes and predictive maintenance that reduces unexpected downtime. Utilizing Ignition’s powerful visualization dashboards, you can gain comprehensive overviews which, in turn, empower operators to swiftly react to anomalies and inefficiencies. Furthermore, MTConnect facilitates standardized data, making it easier to analyze across different platforms and machines.

Implementing these technologies effectively involves several key practices:

-

- Real-time Alerts: Implement instant notifications triggered by performance thresholds to minimize downtime.

-

- Data Collection Automation: Automate the aggregation of operational data for more accurate analysis and reporting.

-

- Performance Benchmarks: Set and track standard performance metrics to gauge operational efficiency.

Best Practices for Implementing Unified CNC Monitoring Systems

Q&A

Q1: What is the main focus of the article “Optimizing CNC Monitoring: Ignition & MTConnect Insights”?

A1: The article primarily delves into how modern manufacturers can enhance the efficiency and productivity of their CNC machines through advanced monitoring solutions. It explores the synergy between Ignition—a modular software platform by Inductive Automation—and MTConnect, an open-source communication protocol designed for seamless data collection from CNC machines.

Q2: How does Ignition contribute to CNC monitoring optimization?

A2: Ignition revolutionizes CNC monitoring by providing a unified platform for visualizing and analyzing machine data. Its modular and scalable architecture allows manufacturers to integrate various data sources, including MTConnect-compliant devices. With powerful tools for real-time data visualization, historical analysis, and event handling, Ignition facilitates comprehensive monitoring and predictive maintenance, significantly reducing downtime and improving overall machine performance.

Q3: What role does MTConnect play in this optimization process?

A3: MTConnect acts as a crucial enabler in the optimization process by standardizing the way data is collected and transmitted from diverse CNC machines and other manufacturing equipment. By ensuring consistent data formats and structures, MTConnect makes it easier for Ignition and other analytics tools to process and interpret information, helping manufacturers gain actionable insights into machine performance and operational efficiency.

Q4: Can you explain how the combination of Ignition and MTConnect benefits manufacturers?

A4: The integration of Ignition and MTConnect offers a potent combination that empowers manufacturers with a holistic and transparent view of their production processes. Ignition’s flexible, user-friendly interface coupled with MTConnect’s robust data extraction capabilities enables real-time monitoring, quick identification of inefficiencies, and informed decision-making. This leads to proactive maintenance strategies, reduced machine downtime, and optimized resource utilization, ultimately boosting productivity and profitability.

Q5: What are some specific features of Ignition that enhance CNC monitoring?

A5: Ignition boasts a plethora of features tailored for optimal CNC monitoring, including customizable dashboards, real-time data tracking, and alerting mechanisms. It also excels in data integration, allowing manufacturers to seamlessly combine information from multiple machines and systems. Additionally, Ignition supports historical data analysis and predictive analytics, assisting in the detection of trends, anomalies, and potential issues before they escalate.

Q6: How does adopting MTConnect impact the data acquisition process from CNC machines?

A6: Adopting MTConnect simplifies the data acquisition process by providing a standardized communication protocol that ensures consistent and reliable data exchange. It eliminates the complexities associated with proprietary systems and disparate data formats, enabling smoother integration with monitoring platforms like Ignition. This standardization enhances data accuracy and accessibility, facilitating more effective analysis and utilization.

Q7: What are the potential challenges manufacturers might face when implementing Ignition and MTConnect?

A7: While the benefits are significant, manufacturers may encounter challenges such as initial setup costs, the need for technical expertise to integrate and configure the systems, and potential compatibility issues with legacy equipment. However, these challenges can be mitigated through proper planning, training, and leveraging the comprehensive support provided by both Ignition and MTConnect communities.

Q8: How can manufacturers get started with using Ignition and MTConnect for CNC monitoring?

A8: Manufacturers can start by assessing their current monitoring needs and identifying gaps in their existing systems. Next, they should explore the capabilities of Ignition and MTConnect to understand how these tools can address their specific requirements. Collaborating with experts in industrial automation and consulting with solution providers can help ensure a smooth implementation. Additionally, leveraging online resources, tutorials, and training programs can facilitate a more effective onboarding process.

Q9: What future trends in CNC monitoring do Ignition and MTConnect set the stage for?

A9: Ignition and MTConnect pave the way for more sophisticated and connected manufacturing environments. Emerging trends include the integration of IoT devices, advanced machine learning algorithms for predictive maintenance, and enhanced edge computing capabilities. These developments will further enhance data-driven decision-making, drive automation, and improve the overall agility and responsiveness of manufacturing operations.

Q10: why should manufacturers consider optimizing their CNC monitoring with Ignition and MTConnect?

A10: Optimizing CNC monitoring with Ignition and MTConnect enables manufacturers to achieve higher levels of efficiency, productivity, and machine uptime. By providing a robust framework for real-time monitoring, data analysis, and predictive maintenance, these technologies support more informed and strategic decision-making, ultimately leading to improved operational performance and competitive advantage.

Insights and Conclusions

As we traverse this era of rapid technological advancement, the fusion of Ignition and MTConnect emerges as not just a solution but a revolution in CNC monitoring. The precision, efficiency, and insightful analytics gleaned from these integrations carve a pathway to previously uncharted levels of operational excellence.

Yet, mastering this technological symphony requires more than tools—it calls for a partner adept in orchestrating innovation and guiding your journey towards seamless manufacturing integration. At Innorobix Automation, we’re pioneers of possibilities, committed to transforming your CNC monitoring landscapes through tailored, cutting-edge solutions.

Isn’t it time to elevate your manufacturing capabilities? Reach out to Innorobix Automation and let’s unlock the future of CNC together. Your next chapter of optimized performance is just a conversation away.