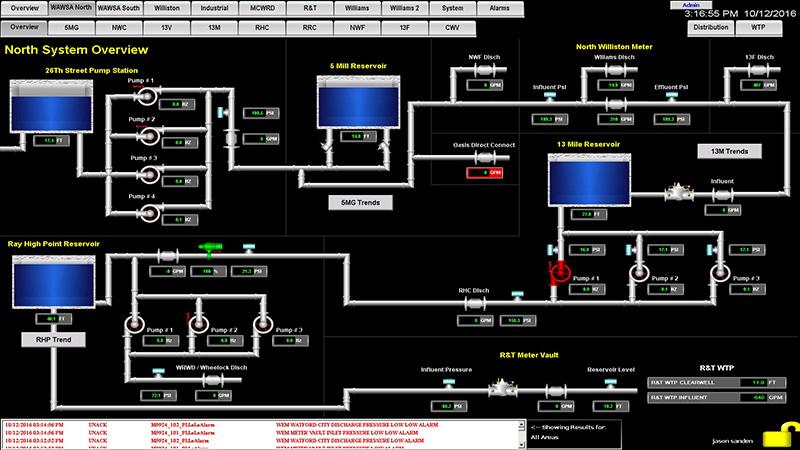

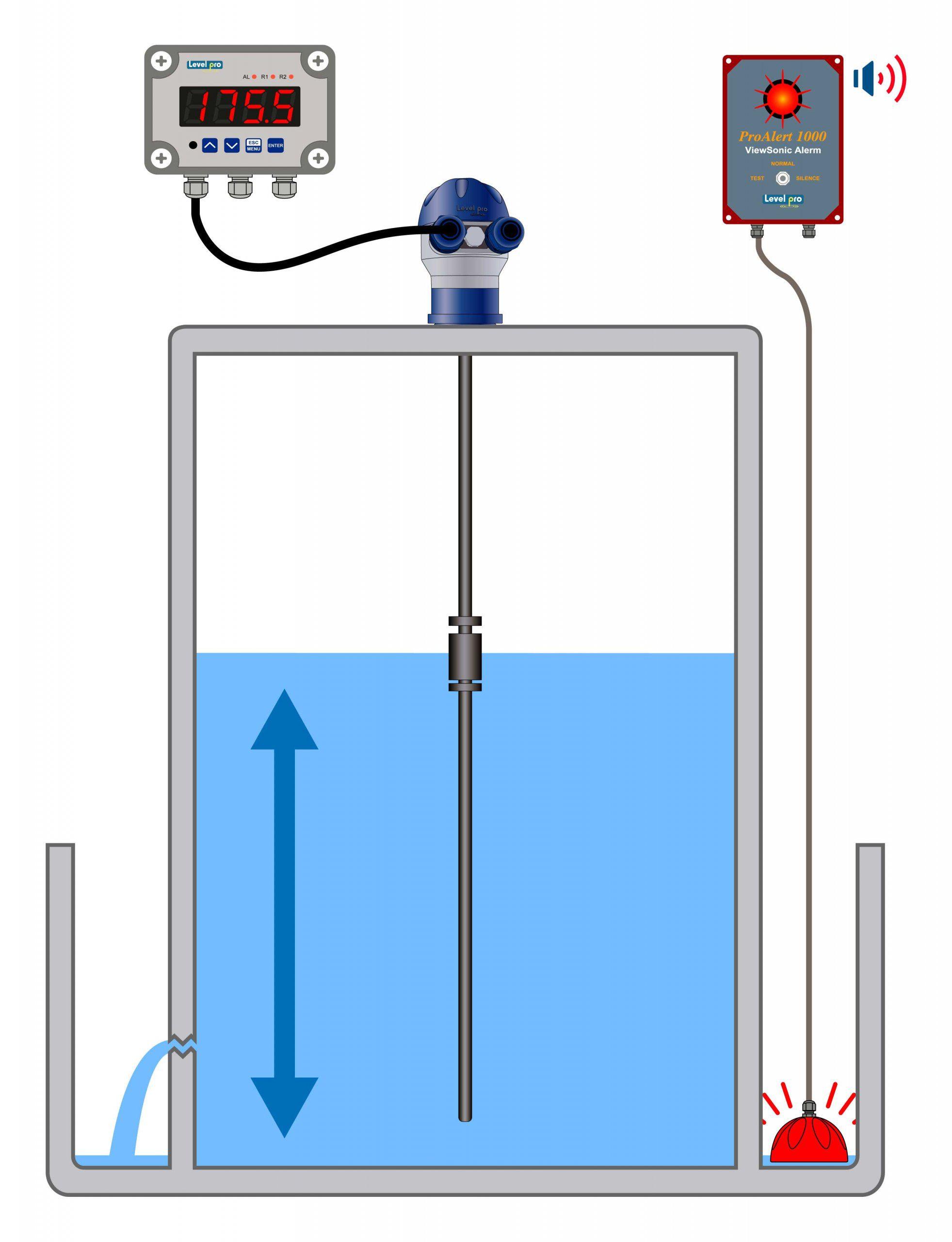

Alerting Operators to Level Anomalies in Real Time

Implement real-time alerts for level anomalies using Ignition's comprehensive monitoring tools. Configure thresholds to trigger notifications via SMS or email, ensuring immediate operator response. Example: If material level drops below 20%, send instant alerts to prevent downtime.