Visualizing Cycle Times by Operator, Job, and Machine

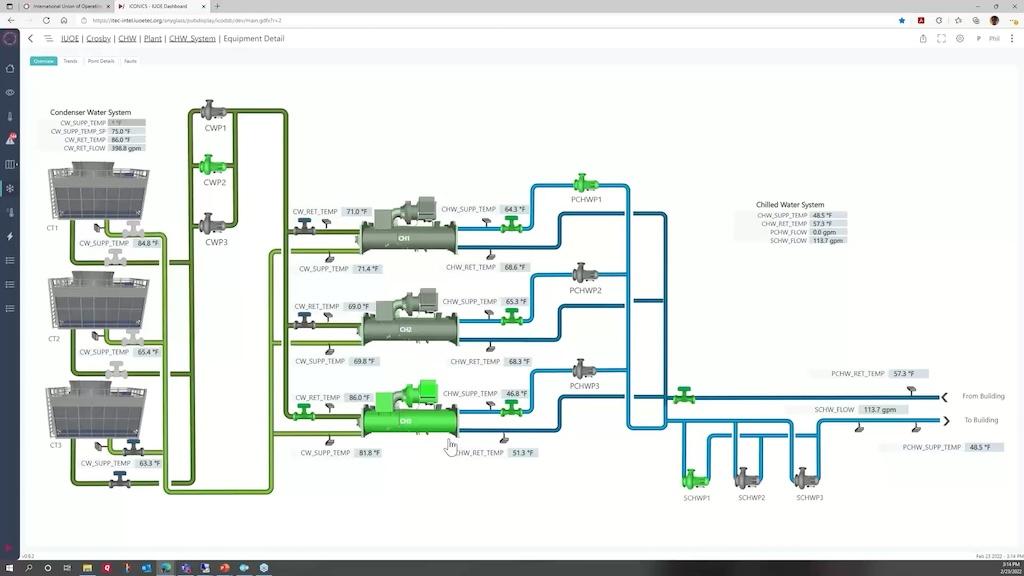

Leverage data to visualize cycle times by operator, job, and machine. For instance, compare Operator A's efficiency on Job X using MTConnect data. Use clear graphs to highlight productivity trends and identify improvement areas.