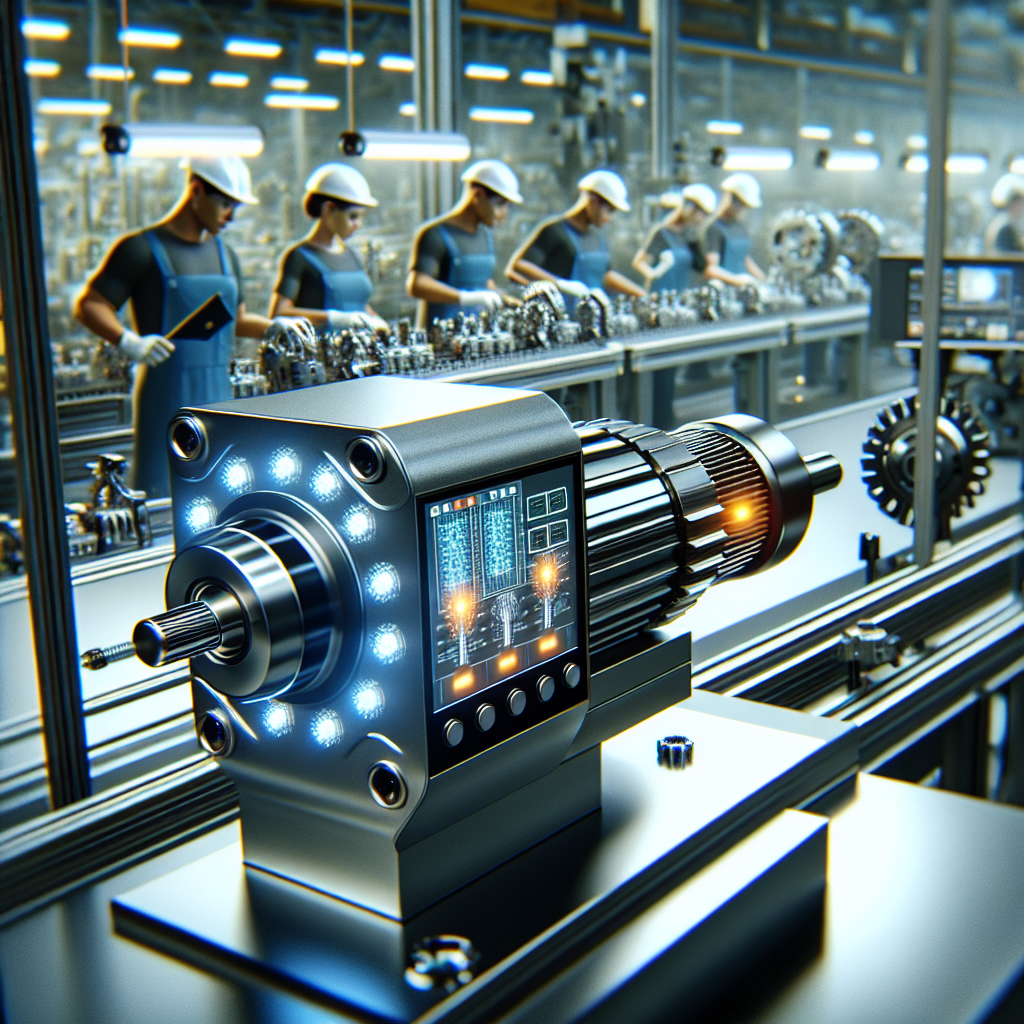

Sturtevant Richmont Integration with SCADA: Simplify Tightening Validation with Open Protocol torque

Unlock seamless integration of Sturtevant Richmont tools with SCADA using Open Protocol to simplify tightening validation. Key benefits include:

- Error-Proofing: Real-time feedback eliminates tightening errors.

- Enhanced Traceability: Automatic logging ensures compliance.

- Two-Way Communication: Streamlined data flow boosts efficiency.