How to gather CNC OEE data without Serial or Ethernet connection.

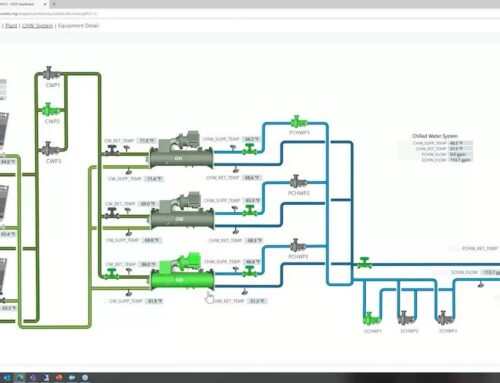

One of the key features of Industry 4.0 , which most manufacturers are trying to achieve is interconnectivity of machines and data collection. Specifically the latter, which is no longer a luxury , but a necessity.

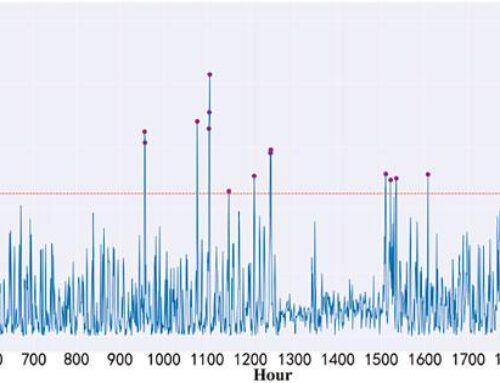

Combining this data with other enterprise data helps you preform analysis on business activities and operations. The results of these data may help your plant run at a better rate and earn you more money.

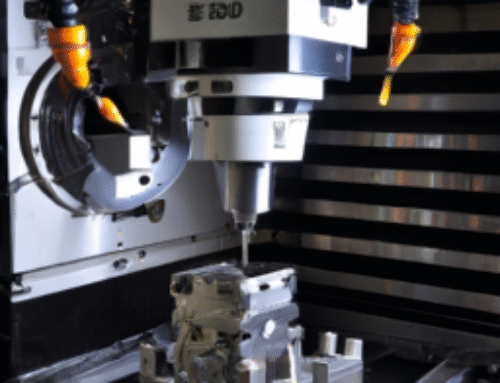

With more and more companies moving to smart manufacturing, its time to move towards connecting your CNC to Scada system. Even older CNCs can improve their OEE by proper production monitoring

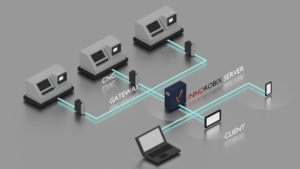

How to connect a CNC to SCADA?

Most CNC manufacturers had their own proprietary protocols to connect to a CNC. This involved buying an expensive licensed software suite for a particular CNC controller and setting it up to collect the production data. It also came with the drawback of maintaining multiple software packages for different CNC types.

This made it hard to bring about one uniform solution which works for everyone. Until the MT connect protocol was introduced which made it easier to connect to any CNC which had an MTconnect adapter.

Today, most CNCs are connected to the plant Scada or shop floor software by either MT Connect or proprietary data collection packages.

How to collect data from a pre MTConnect CNC or without the use of Serial/Ethernet connections?

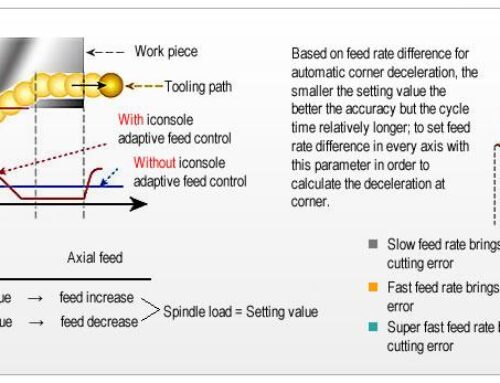

Most of the older CNCs don’t support MTConnect. And some of them don’t even feature proprietary software or hardware support. But fortunately , INNOROBIX Automation has a solution to salvage uptime/downtime for any older CNCs using digital I/O and gateways. Using this system you would still have access to all the data required to get the machine OEE and other critical metric data. Please fill out the form below for more information.